A fully laminating light-curing silicone liquid optical adhesive, a display panel containing it, and a preparation method thereof

A light-curing and silicone technology, which is applied in optics, nonlinear optics, adhesives, etc., can solve the problems of reducing production efficiency and achieve the effects of reducing production costs, high stability, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0097] This preparation example provides a kind of hyperbranched mercapto-modified silicone oil, and its preparation method is as follows:

[0098] (1) Dilute 10 parts of inorganic acid into deionized water according to 1:4, stir evenly, and transfer to a constant pressure dropping funnel;

[0099] (2) Add 25 parts of dimethyldimethoxysilane, 5 parts of trimethoxymercaptosilane, 20 parts of hexamethyldisilane in the flask equipped with stirrer, thermometer, condenser tube and constant pressure dropping funnel, During the stirring process, add the mineral acid diluted with deionized water dropwise, and control the reaction temperature at 60°C until the dropwise addition is completed;

[0100] (3) Slowly drop 40 parts of tetramethoxysilane into the flask, control the reaction temperature at 60°C, and raise the temperature to 85°C for 4 hours after the dropwise addition;

[0101] (4) Wash with 500ml of a mixed solution of deionized water and toluene at a weight ratio of 4:1 unti...

Embodiment 1-4

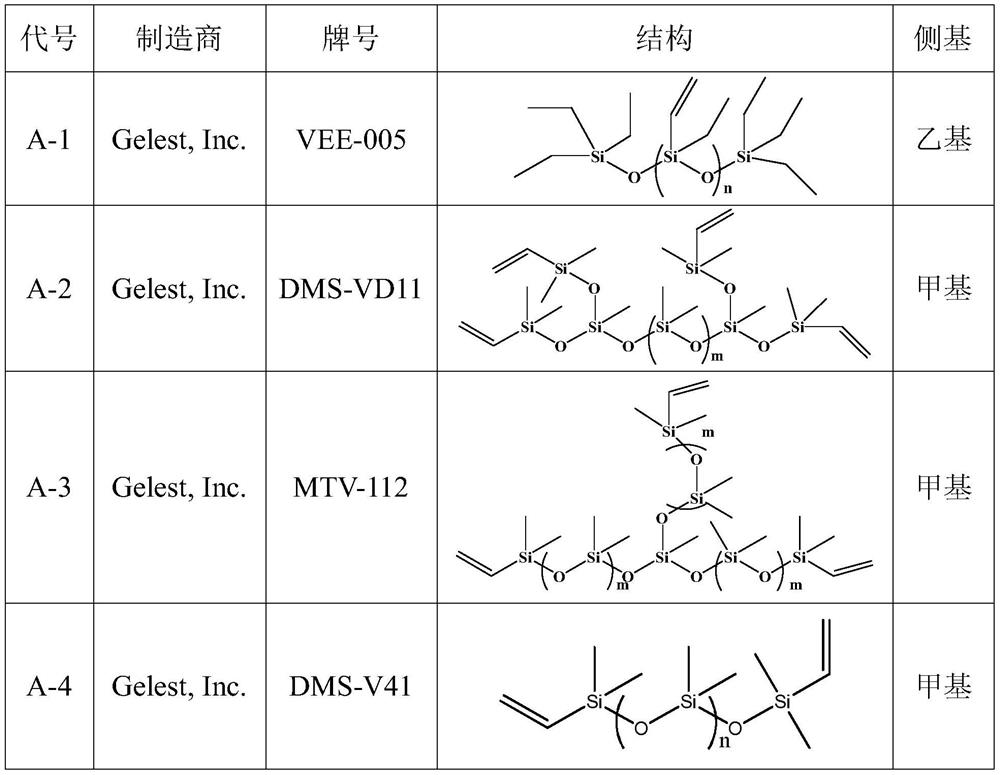

[0121] According to the components shown in Table 1, the frame glue and surface glue of light-curing silicone liquid optical glue were prepared.

[0122] Table 1

[0123]

[0124]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com