Inner diameter detection device

A detection device and inner diameter technology, which is applied in the mechanical field, can solve the problems affecting the accuracy of the pipeline and the vibration of the inner diameter detection device, and achieve the effect of reducing the impact and small vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

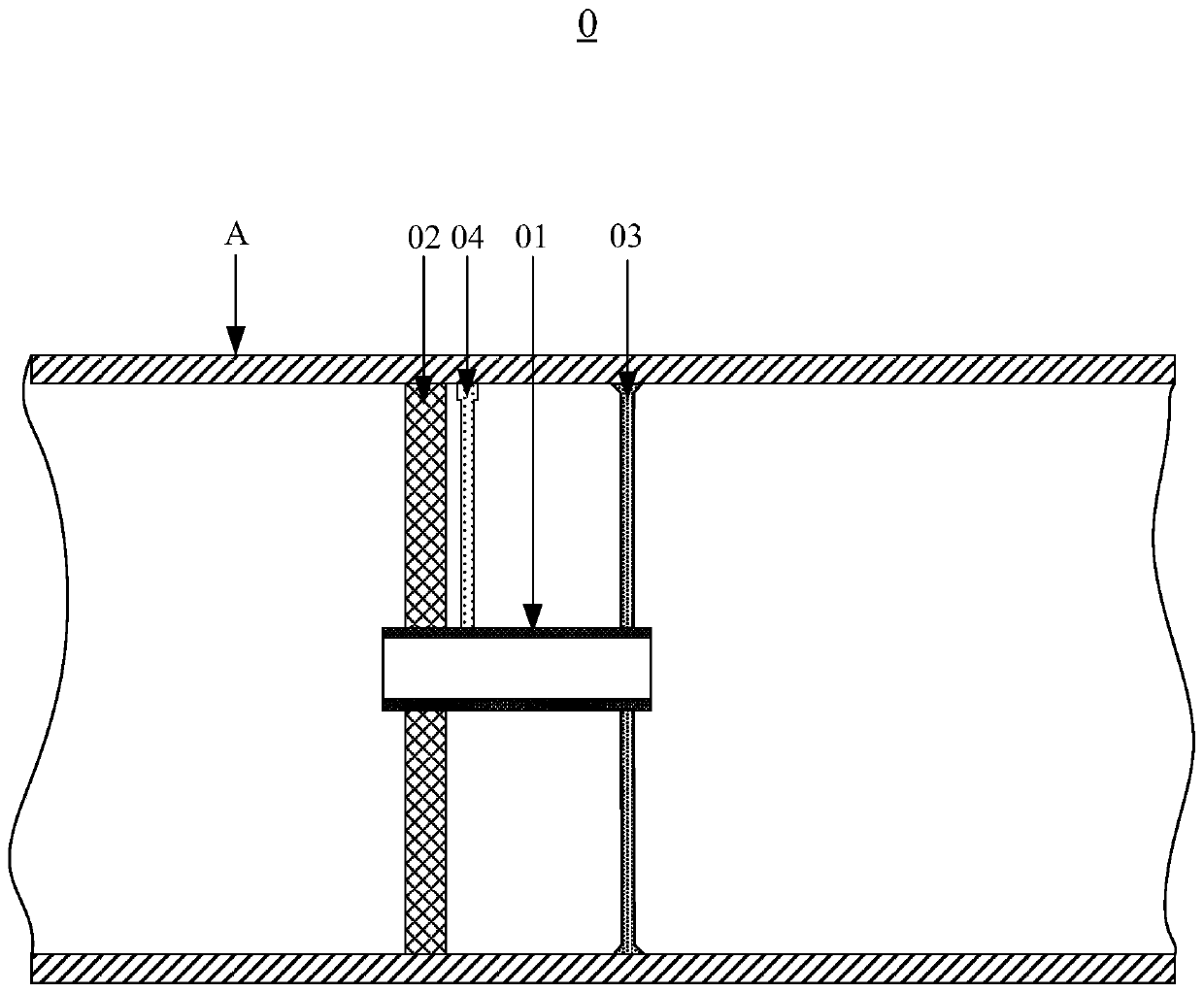

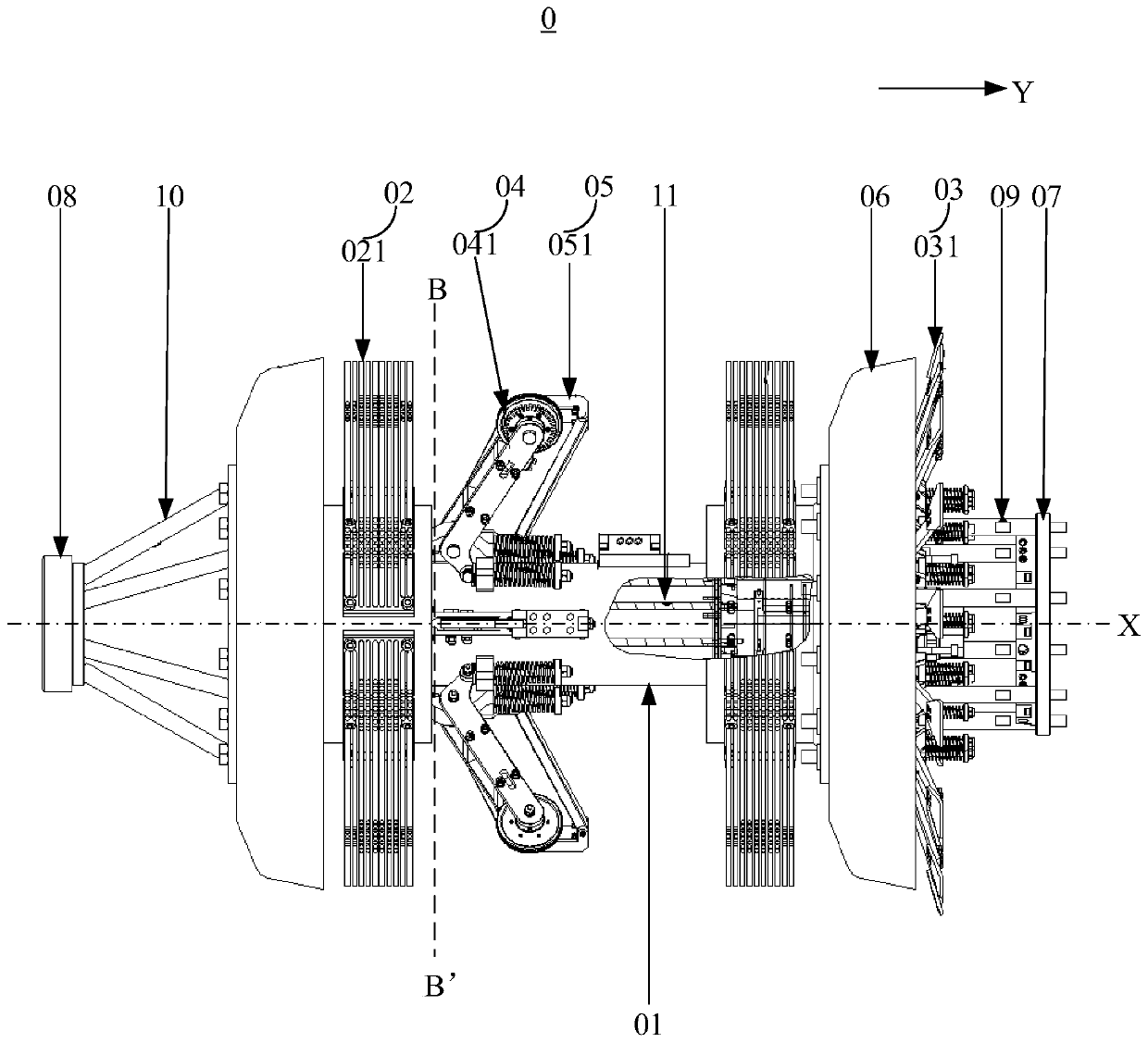

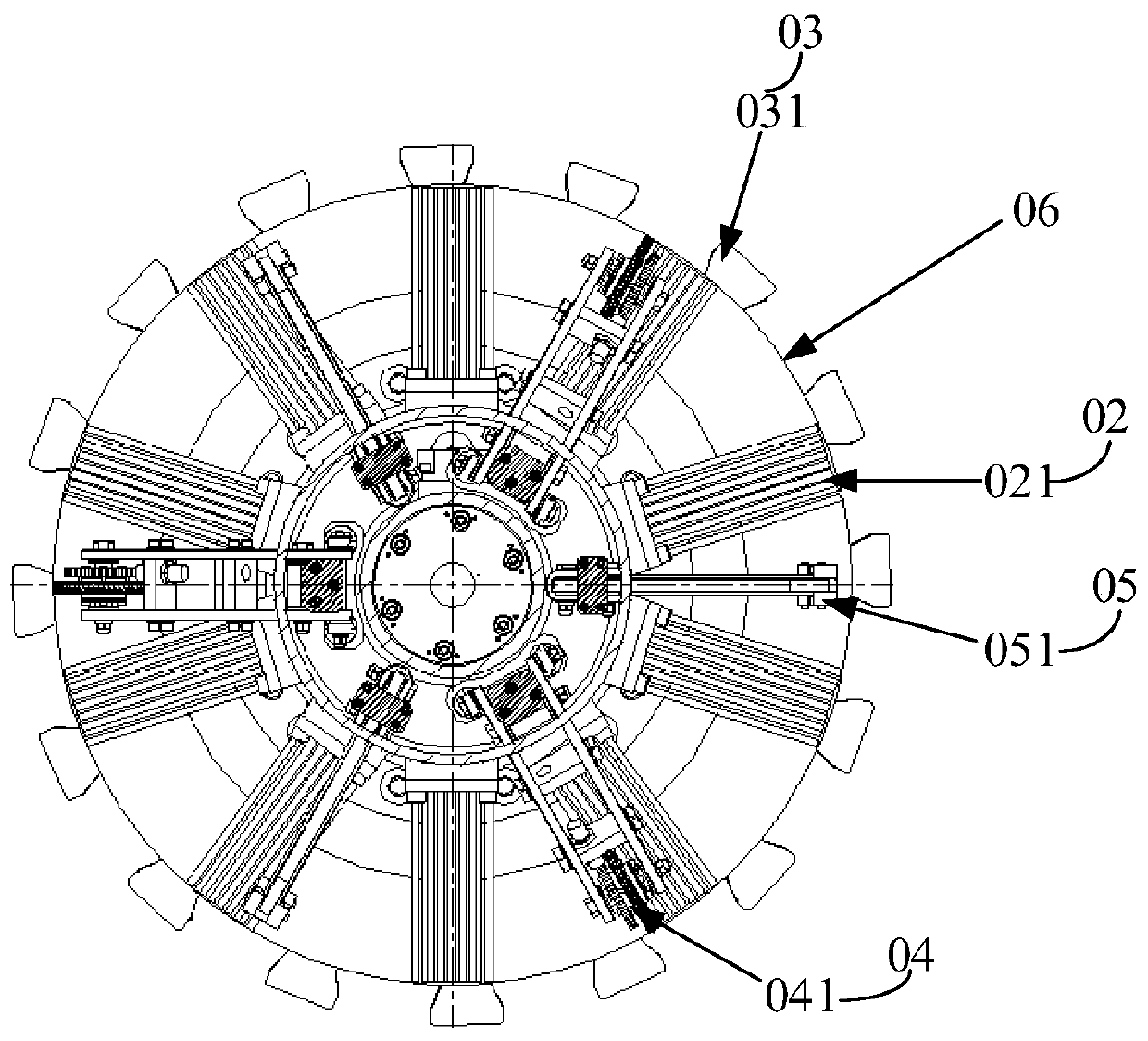

[0029] Since the inner diameter detection device in the related art is easily affected by the girth weld when detecting the inner diameter of the oil and gas pipeline, the embodiments of the present invention provide other inner diameter detection devices. Exemplarily, figure 1 It is a schematic structural diagram of an inner diameter detection device provided by an embodiment of the present invention. like figure 1 As shown, the interior warp detection device 0 may include: a main cylinder 01 , and a steel brush assembly 02 , a geometric probe assembly 03 and an odometer assembly 04 located on the outer wall of the main cylinder 01 .

[0030] Among them, the steel brush assembly 02 is used to support the inner wall of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com