Equipment reference rapid leveling method

A technology of equipment and reference, which is applied in the field of rapid leveling of equipment reference, which can solve the problems of large time consumption and slow adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

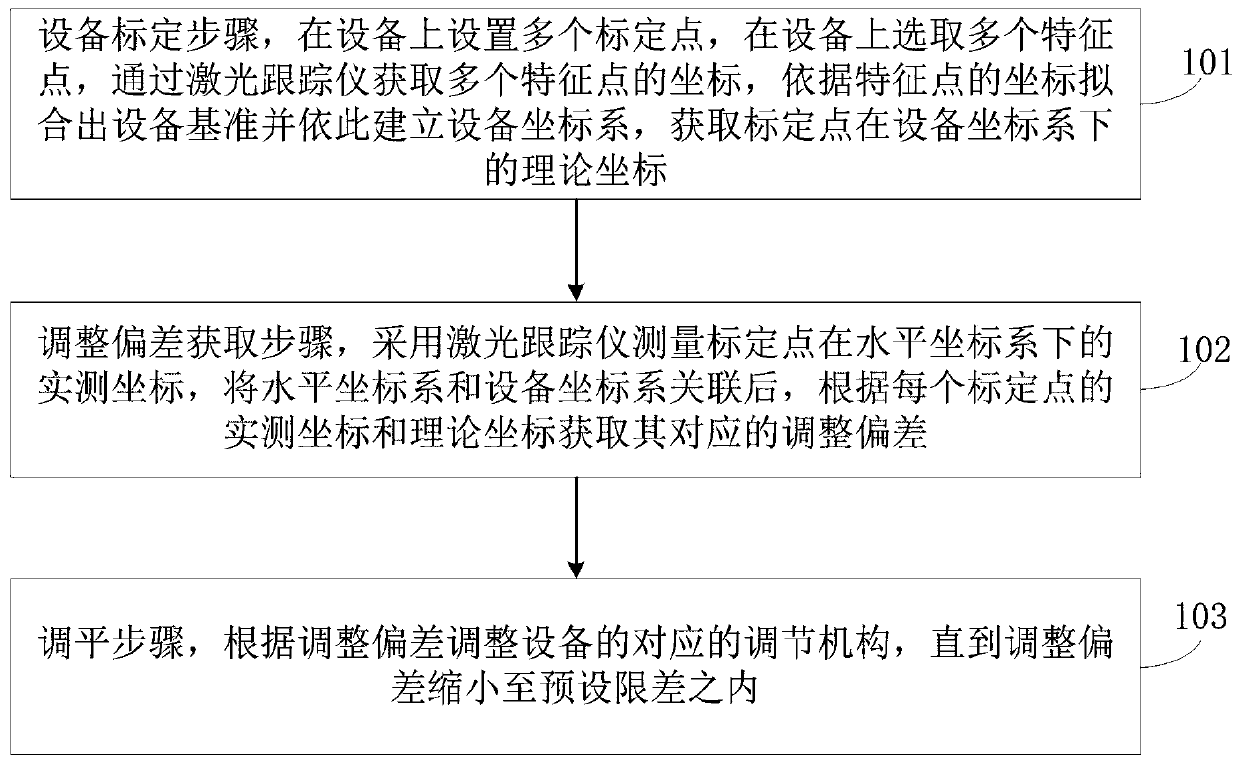

[0059] Please refer to figure 1 and figure 2 , this embodiment provides a method for quickly leveling equipment references, the method comprising:

[0060] Step 101: The device calibration step, setting multiple calibration points on the device, selecting multiple feature points on the device, obtaining the coordinates of multiple feature points through the laser tracker, fitting the device reference according to the coordinates of the feature points and then Establish a device coordinate system and obtain the theoretical coordinates of the calibration point in the device coordinate system;

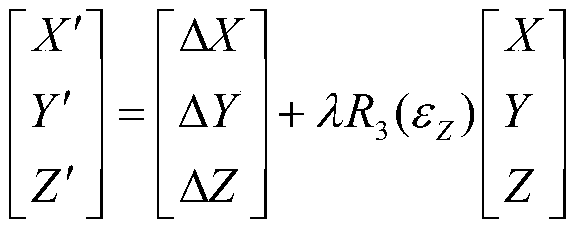

[0061] Step 102: Adjust the deviation acquisition step, use the laser tracker to measure the actual coordinates of the calibration points in the horizontal coordinate system, associate the horizontal coordinate system with the equipment coordinate system, and obtain the corresponding coordinates according to the actual measurement coordinates and theoretical coordinates of each calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com