Method for measuring flow parameter distribution in particle fluid two-phase flow reactor

A technology of flow parameters and measurement methods, which is applied in the field of two-phase flow reaction of particle fluids, can solve the problems of distortion of particle concentration and pressure drop distribution in the flow field, complicated calculation methods, and large amount of calculation. The effect of simplicity, improved precision and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

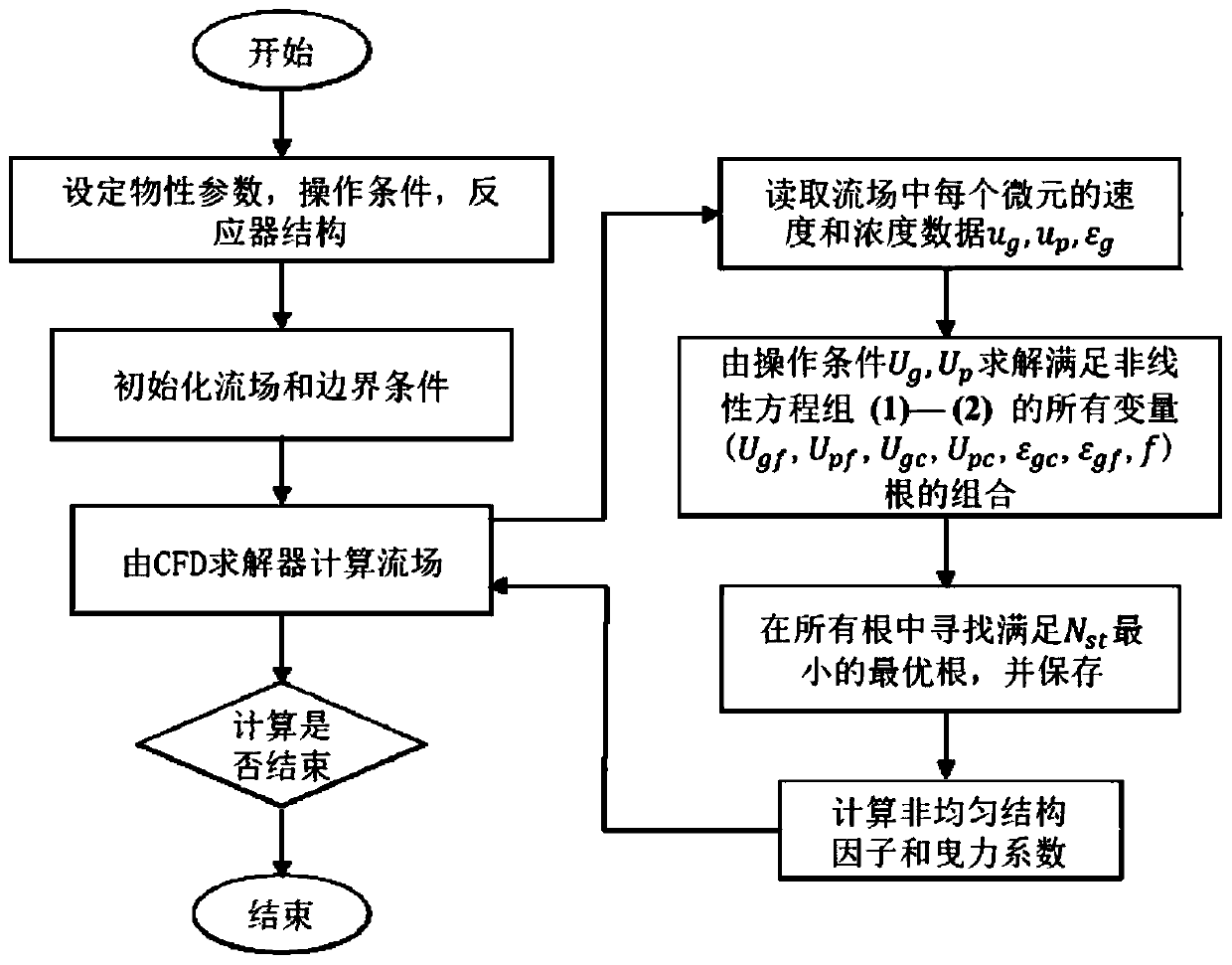

[0096] This embodiment provides a method for measuring flow parameter distribution in a particle fluid two-phase flow reactor, the method comprising the following steps:

[0097] (1) According to the physical parameters and operating conditions of the fluid, initialize the flow field and boundary conditions; the initial flow field and boundary conditions are to specify the structural size, Particle size, particle density, fluid density, fluid viscosity, superficial fluid velocity, and particle flow flux;

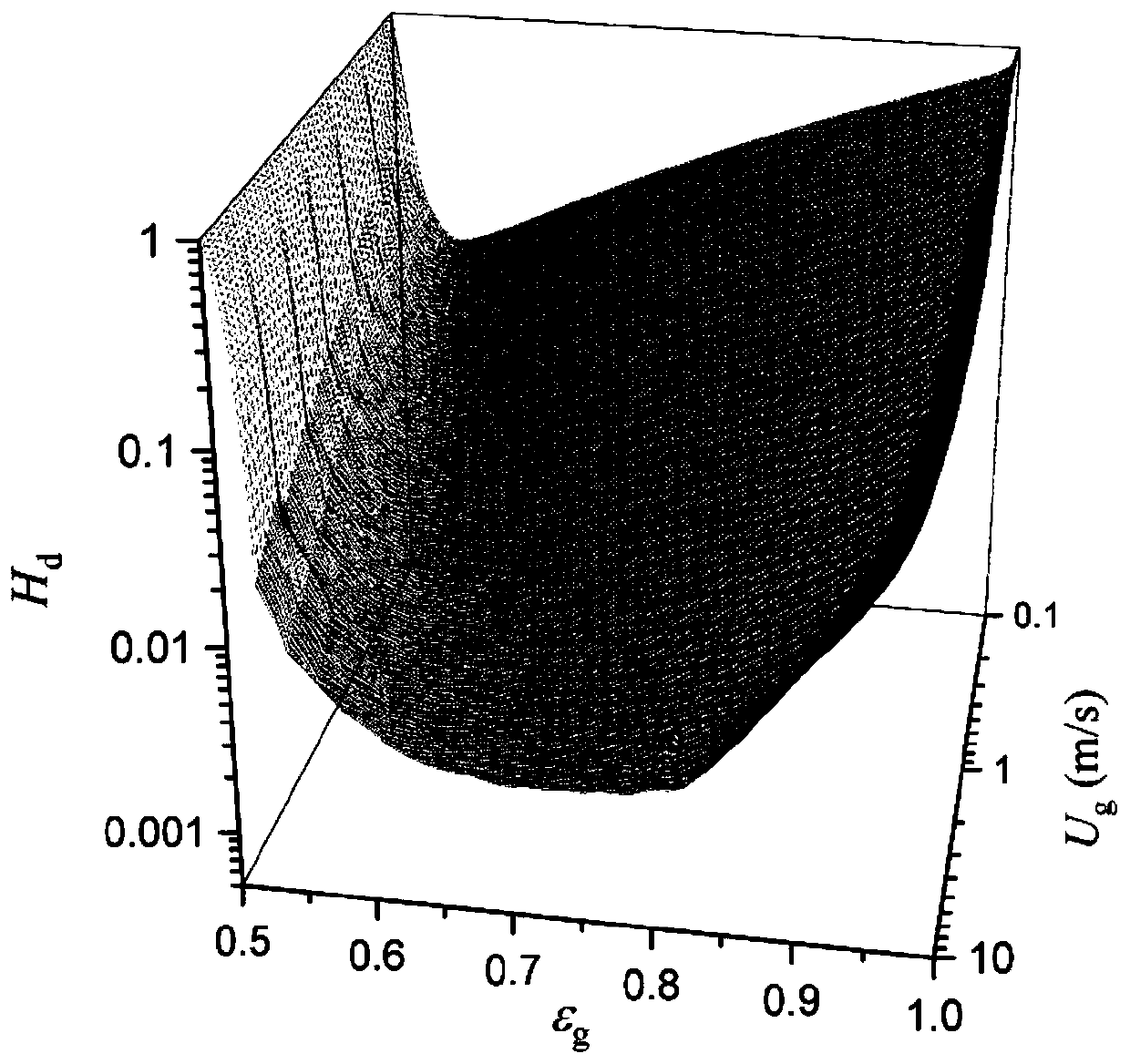

[0098] (2) Calculate the mass conservation equation and the momentum conservation equation in each space micro-element, read the velocity distribution and concentration distribution in the space micro-element, and use the parameter u for the velocity distribution and concentration distribution in the space micro-element g , u p and ε g means, among them, u g Indicates the real velocity of the fluid in the space element, u p Indicates the real velocity of the solid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com