Product production information management method

A technology of production information and management methods, applied in the field of product production information management, can solve problems such as low production efficiency, recording errors, and inability to meet mass production, and achieve the effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

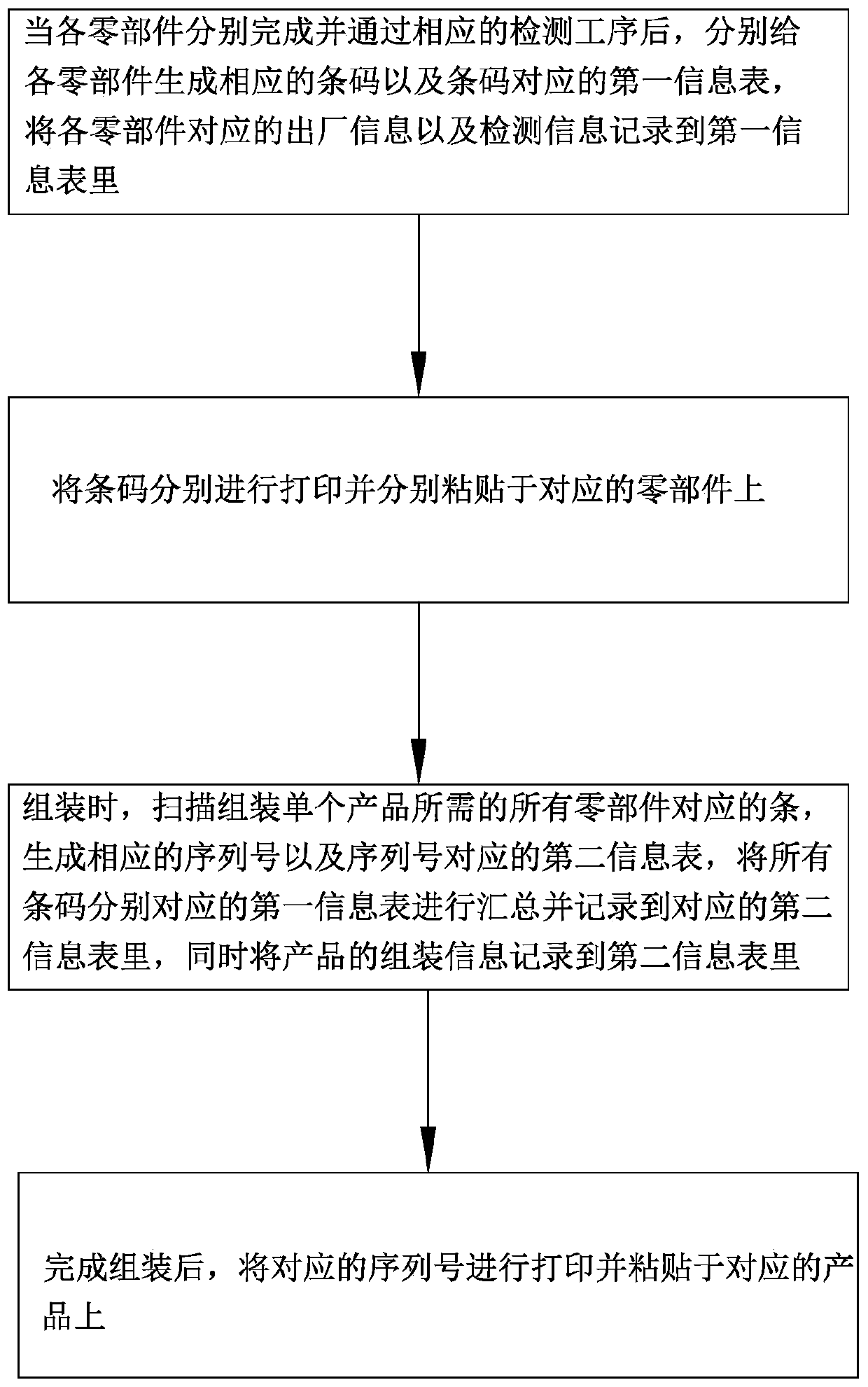

[0022] refer to figure 1 , is a preferred implementation manner, a method for managing product production information, comprising the following steps:

[0023] After each component is completed and passed the corresponding testing process, the corresponding barcode and the first information table corresponding to the barcode are generated for each component, and the factory information and testing information corresponding to each component are recorded in the corresponding first information Inside and outside;

[0024] Print the barcodes separately and paste them on the corresponding parts;

[0025] During assembly, scan the barcodes corresponding to all parts required for assembling a single product, generate the corresponding serial numbers and the second information sheet corresponding to the serial number, summarize and record the first information sheet corresponding to all the barcodes on the product to In the corresponding second information table, record the assembl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap