Winding displacement structure of capacitor motor stator winding and working method thereof

A technology of motor stator and wire structure, applied in the shape/style/structure of winding conductors, electric components, magnetic circuit shape/style/structure, etc., can solve the problems of insufficient phase winding, small torque, low efficiency, etc., and achieve saving The effect of electrical energy, increased work efficiency and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

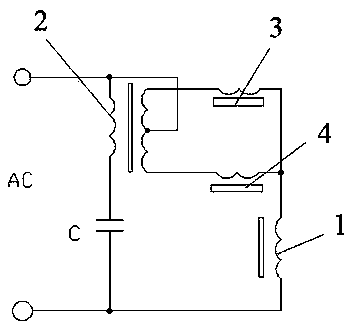

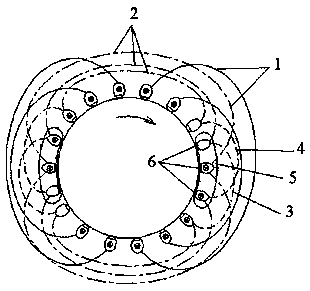

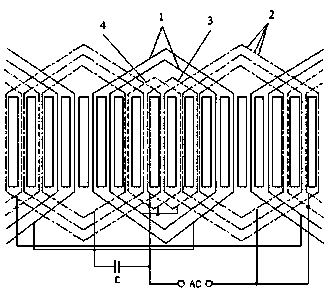

[0031] as attached figure 1 to attach image 3 As shown, a wire arrangement structure of the stator winding of a capacitor motor includes a main winding 1 and an auxiliary winding 2 embedded in the stator slot. The main winding 1 and the auxiliary winding 2 are separated by a phase angle of 90°. It is a concentric distributed winding, and also includes a shunt winding. The shunt winding is distributed in the stator slot inside the corresponding position of the main winding 1. The shunt winding includes the first shunt winding 3 and the second shunt winding 4. The first shunt winding 3 refers to the auxiliary winding 2 The electrode phase of the first shunt winding 3 is shifted to the left by a set angle, the right side of the electrode of the first shunt winding 3 is overlapped on the right side of the electrode of the secondary winding 2, and the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com