On-line scrubbing system for plate in suspended motion

A board and movement technology, which is applied in the field of online scrubbing system for boards in suspension movement, can solve the problems of low product manufacturing efficiency, time-consuming and laborious, etc., and achieve the effect of reducing labor costs, reducing complicated procedures, and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

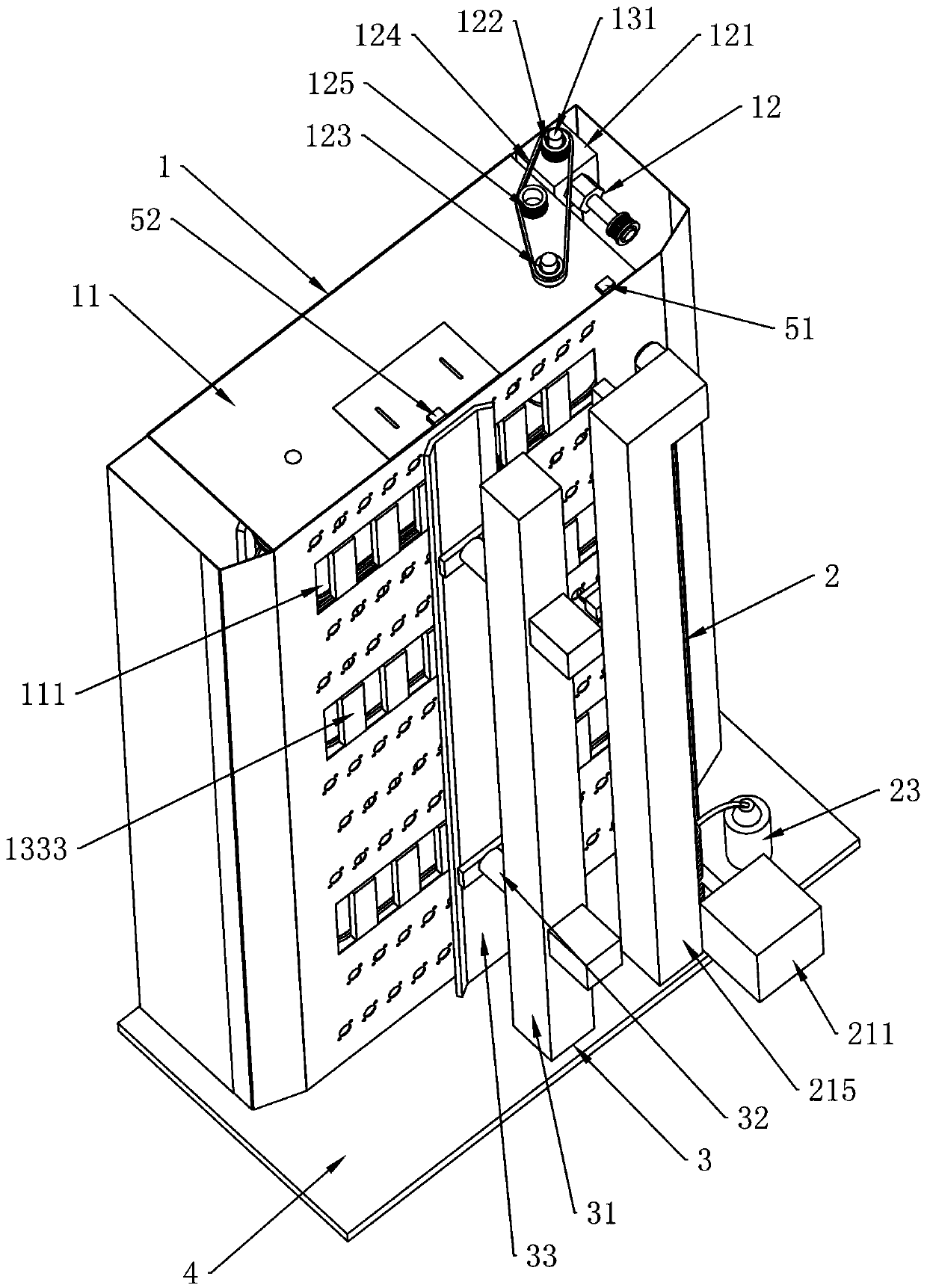

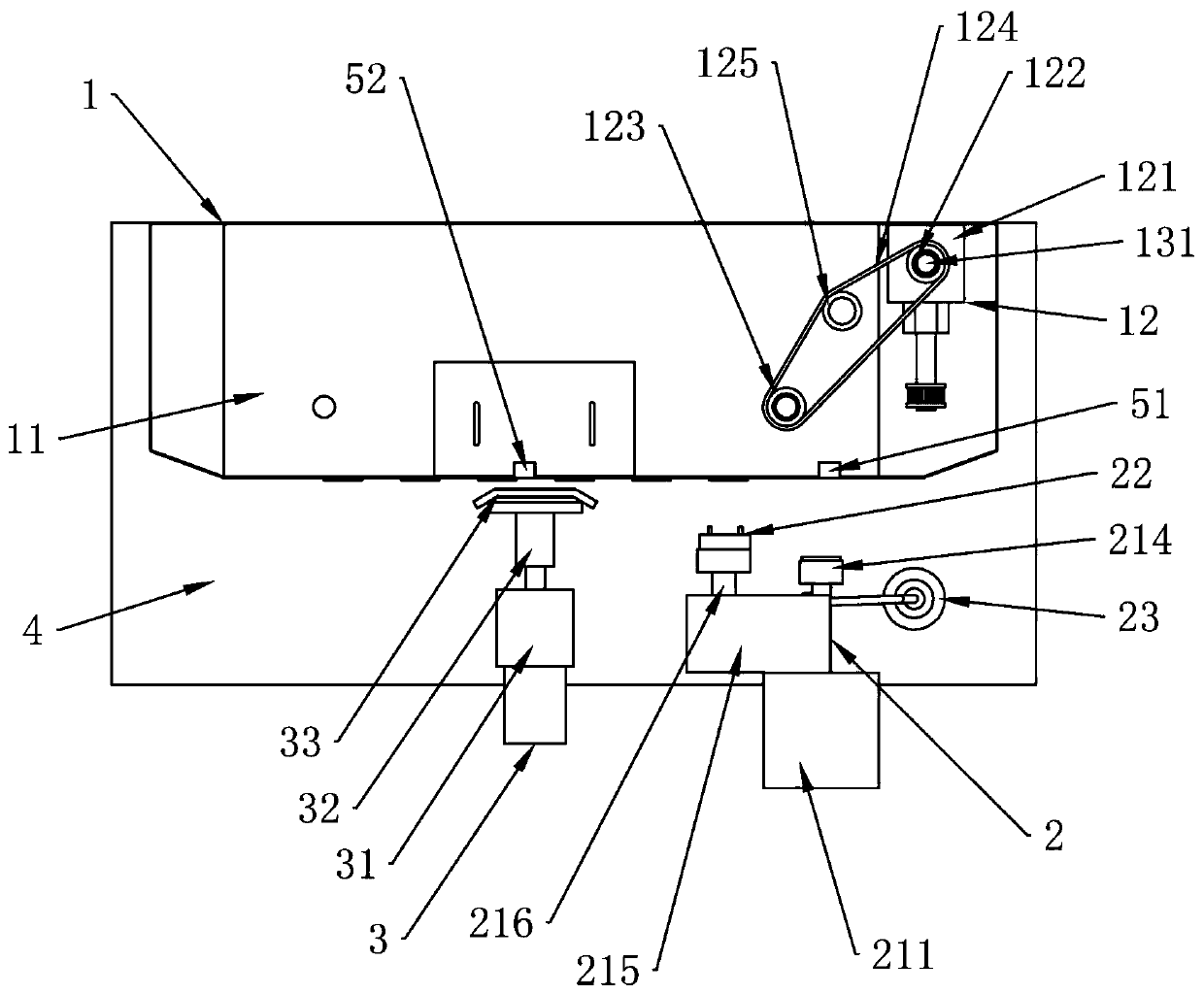

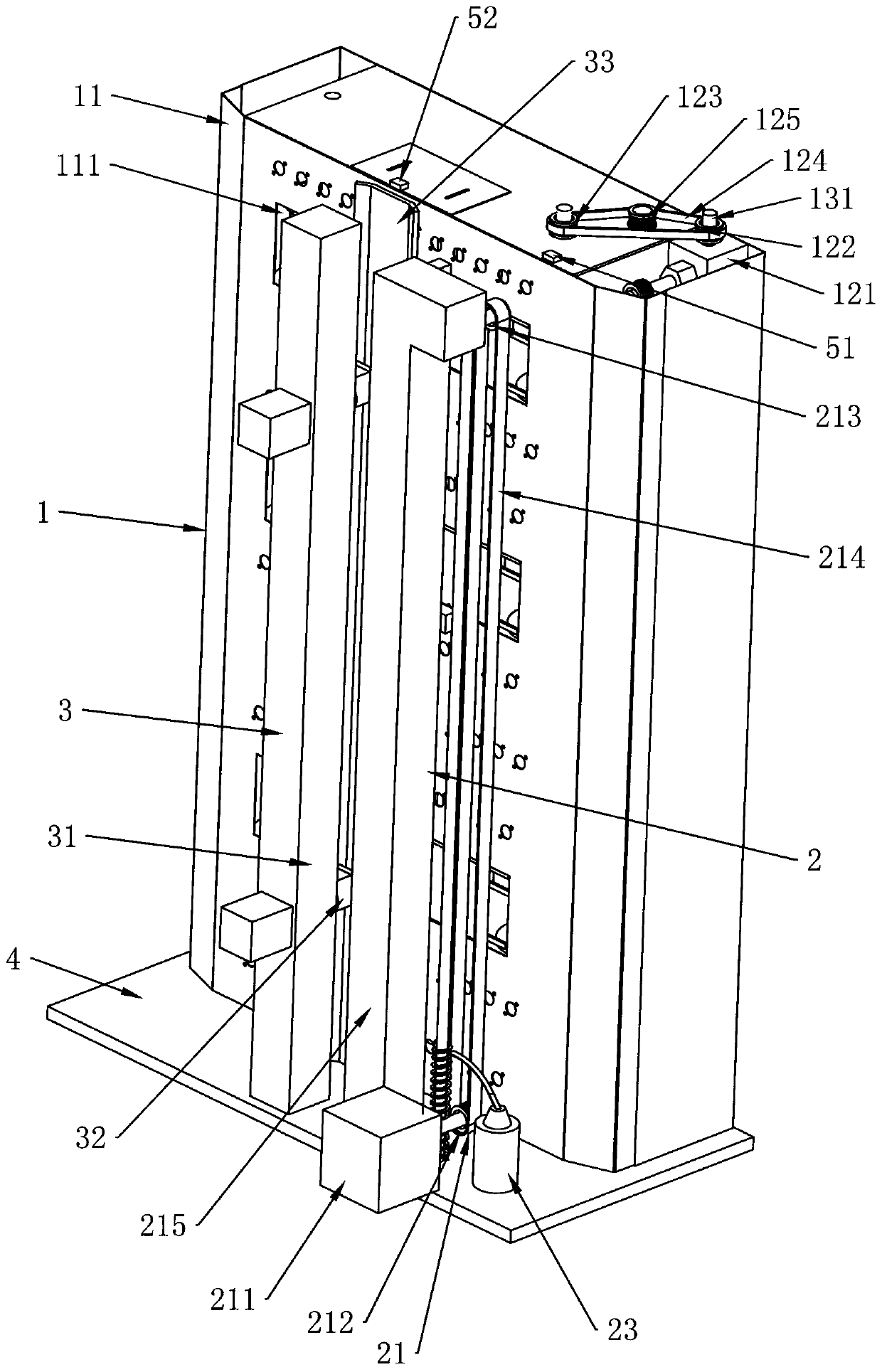

[0056] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, the first drive mechanism 12 includes: a first motor, a steering gear box 121, a first driving wheel 122 and a first driven wheel 123, the input end of the steering gear box 121 is connected to the first motor in transmission, and the first driving wheel 122 The first driven wheel 123 is mounted on the driving shaft 131 , and is connected to the first driving wheel 122 through the first belt 124 . Preferably, the steering gearbox 121 is a 90° steering gearbox.

[0057] Preferably, the first motor can also drive the input end of the steering gear box 121 through a belt assembly.

[0058] In a further embodiment of the present invention, the first driving mechanism 12 further includes: a tensioning wheel 125 , and the tensioning wheel 125 is in transmission connection with the first belt 124 .

[0059] In a further embodiment of the present invention, the automat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap