Side band preheating device of side sealing machine

A technology of preheating device and edge banding machine, which is applied to wood processing appliances, household components, etc., can solve problems such as weak bonding of edge bands, no edge band preheating, production loss, etc., and achieve firm edge banding and strengthening The effect of adhesion and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

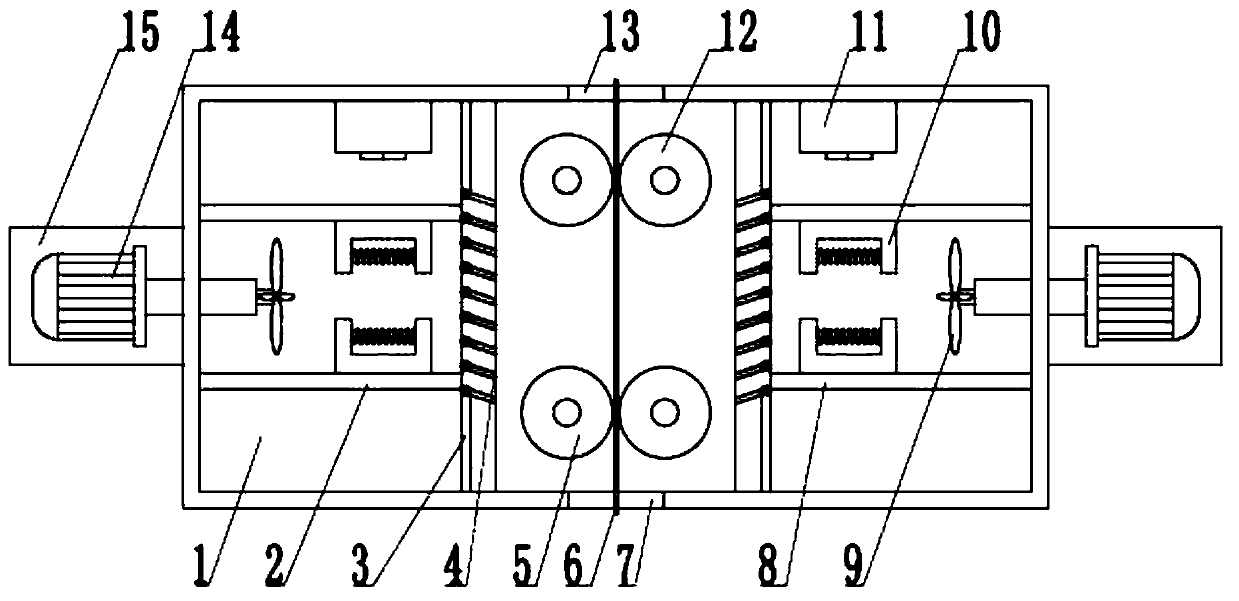

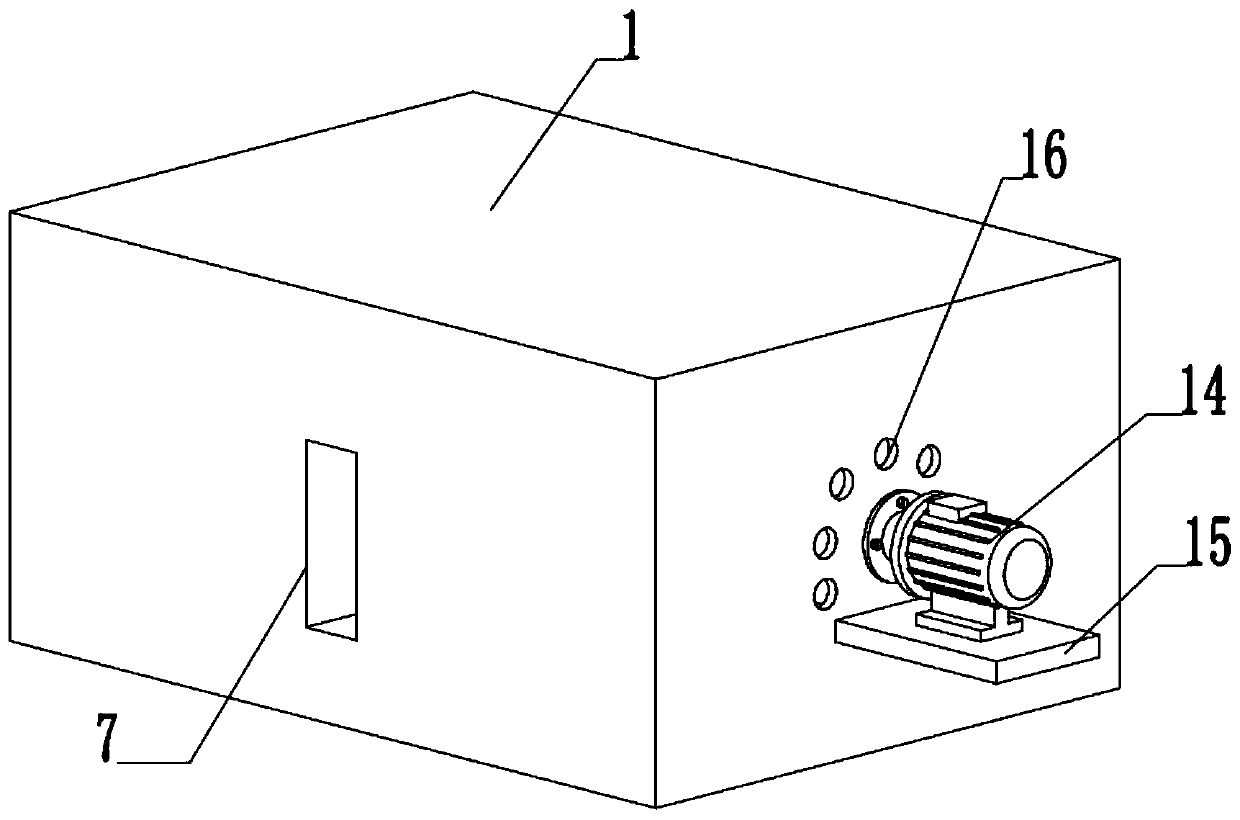

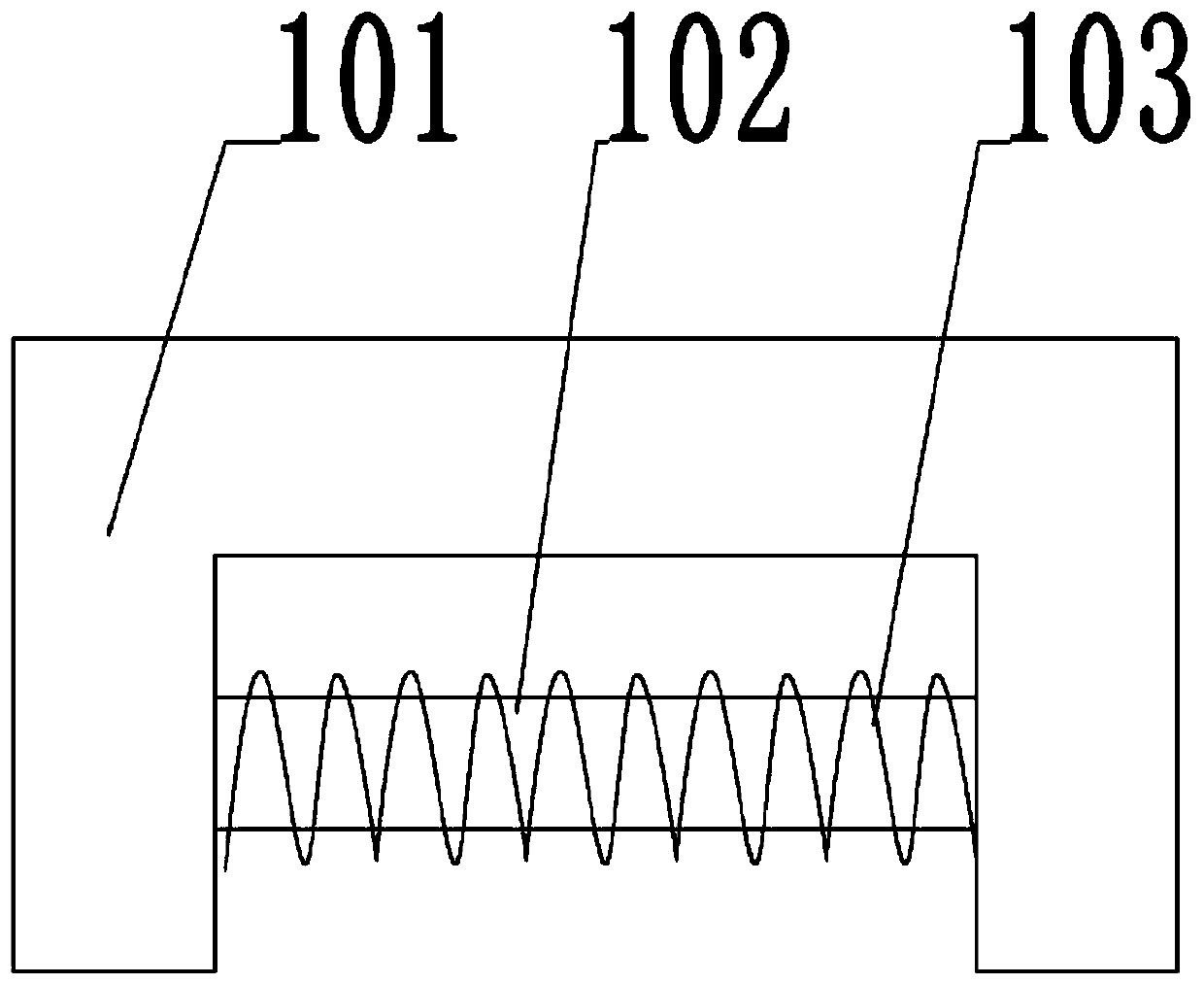

[0021] see Figure 1-3 , a sideband preheating device for an edge banding machine, comprising a main box body 1, a preheating box 3 is arranged in the main box body 1, and a No. 1 idler group 12 and a No. Roller group 5, louver air guide vanes 4 are arranged on the side walls of both sides of the preheating box 3, No. 1 heating chamber 2 and No. 2 heating chamber 8 are respectively arranged on both sides of the preheating box 3, the No. 1 heating Both sides of the inner wall of chamber 2 and No. 2 heating chamber 8 are equipped with heating device 10, and one side of heating device 10 is provided with micro fan 9, and the side walls on both sides of the main box body 1 are fixedly connected with support plate 15, and on the support plate 15 The motor 14 is fixedly connected, and the drive shaft of the motor 14 passes through the side wall of the main box body 1 and extends into the heating chamber.

[0022] A power supply 11 is arranged in the main box body 1 on one side of t...

Embodiment 2

[0024] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the No. 1 heating chamber 2 and the No. 2 heating chamber 8 are all communicated with the preheating box 3 through the louver air guide vane 4, and the main box body 1 Air inlet holes 16 are provided on both side walls.

[0025] During the implementation of the present invention, the sideband 6 enters the inside of the preheating box 3 in the main box body 1 through the sideband inlet 13 during use, and the sideband 6 passes through the No. 1 roller group 12 and the No. 2 roller group 5, and the motor is started. 14. Drive the micro fan 9 to rotate, connect the power supply 11 with the heating device 10 through the switch, and the micro fan 9 will bring the outside wind into the No. 1 heating chamber 2 and No. The hot air is generated, transported to the preheating box 3 through the louver air guide 4, and preheats the two sides of the side belt 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com