Method for predicting reversing track of semi-trailer train without hinge angle sensor

A technology of angle sensor and automobile train, which is applied in the field of semi-trailer steering control, can solve the problems of cumulative error, high cost, and insufficient precision, and achieve the effects of eliminating cumulative error, improving safety, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

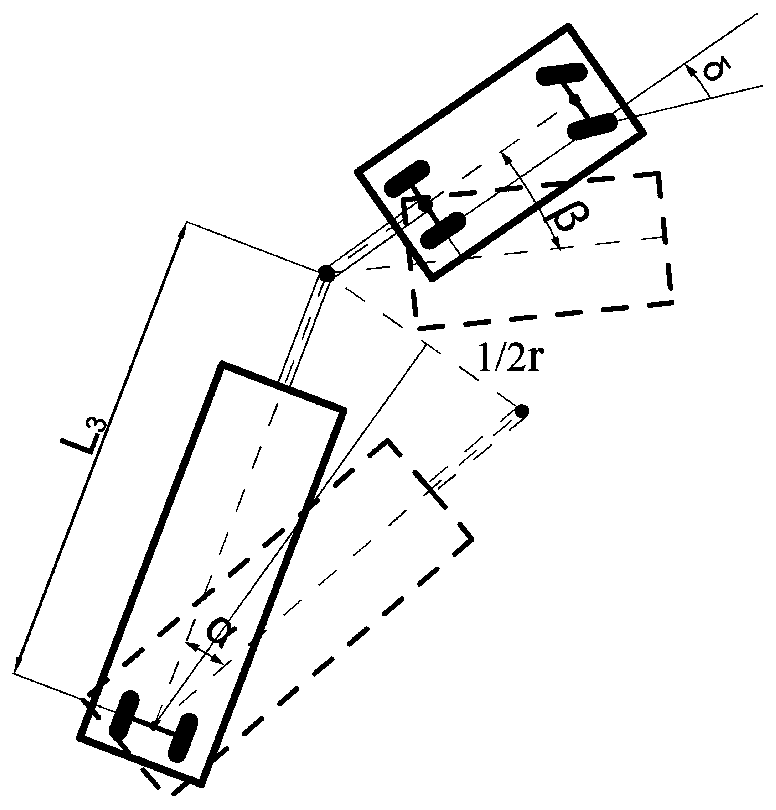

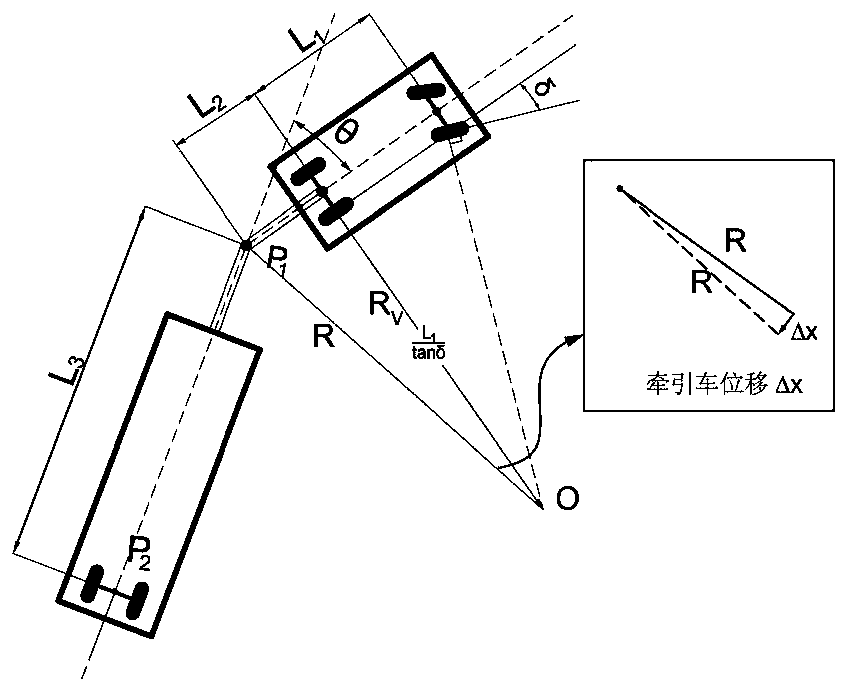

[0042] In this embodiment, a method for predicting the reversing trajectory of a semi-trailer train without an articulation angle sensor is to obtain the change trend of the articulation angle through a numerical accumulation method, and perform initial calibration by adding a check digit The initial articulation angle is zero, and the process verification is carried out through the check digit while accumulating the instantaneous change of the articulation angle, so as to eliminate the error in the numerical calculation, so that it can be carried out through the structure and kinematic relationship between the tractor and the semi-trailer t 1Prediction of reversing trajectory after time. Specifically, proceed as follows:

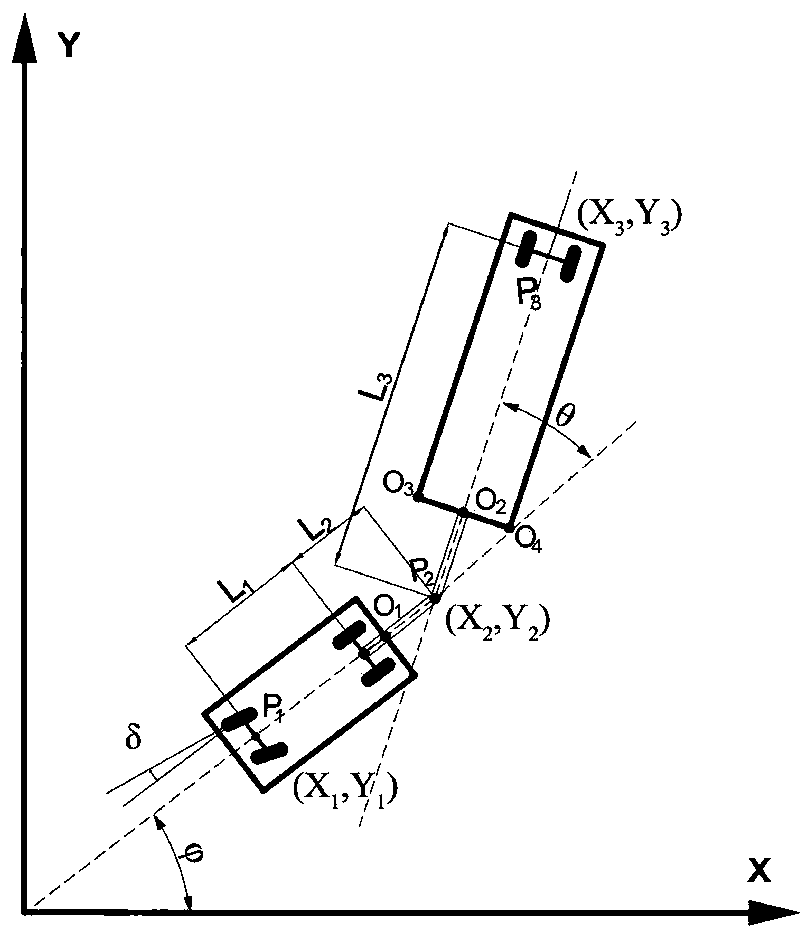

[0043] Step 1, such as figure 1 As shown, take any point on the extension line of the central axis of the tractor as the origin, and establish a Cartesian coordinate system, and determine the coordinates of the center point of the front axle of the tracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com