Glue pressing equipment

A glue-pressing and equipment technology, which is applied in the direction of sewing tools, etc., can solve problems such as difficult to control the position interval intuitively, wrong pressing of edge curling on both sides, twisting and stagnation, etc., so as to improve the guiding transmission effect and ensure flexibility Intuitive and accurate effect of adjustment and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

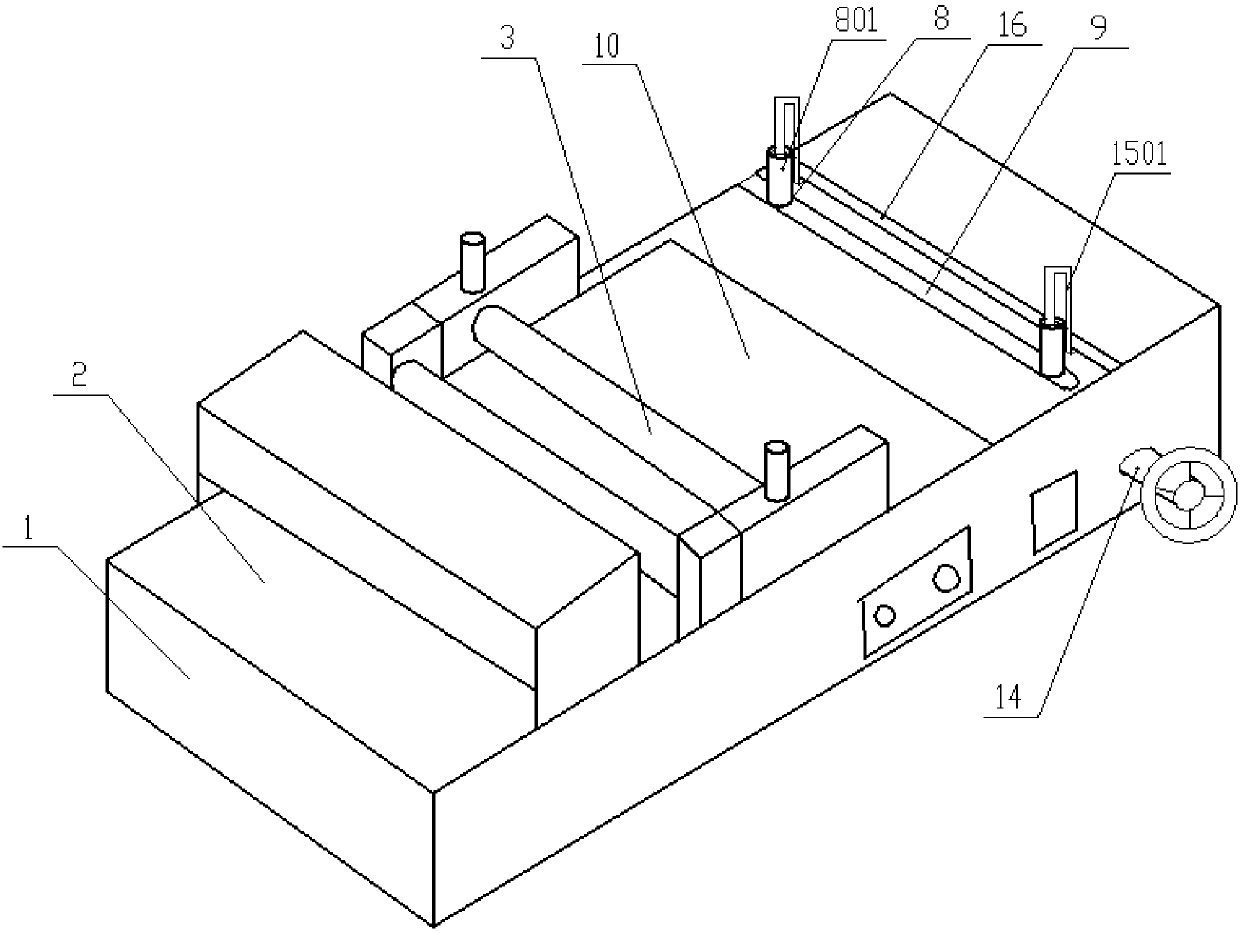

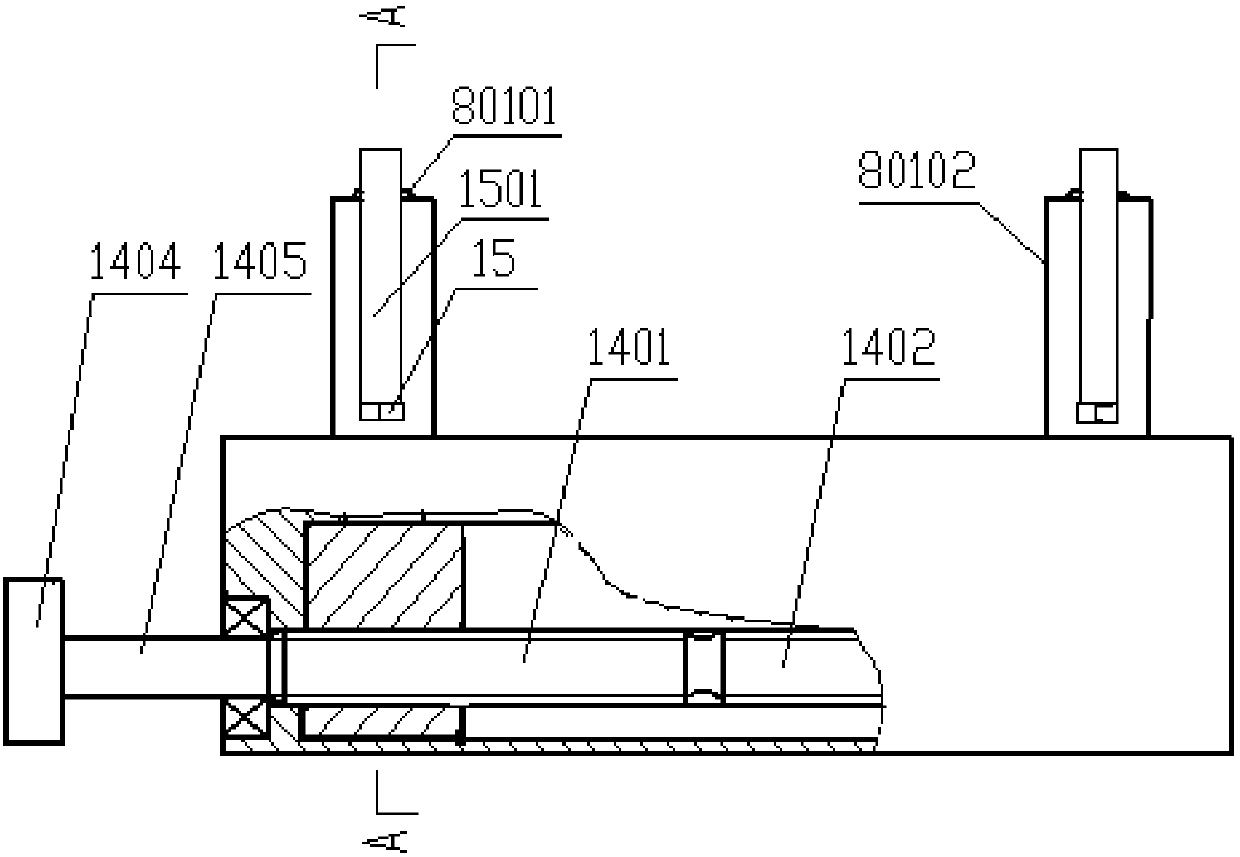

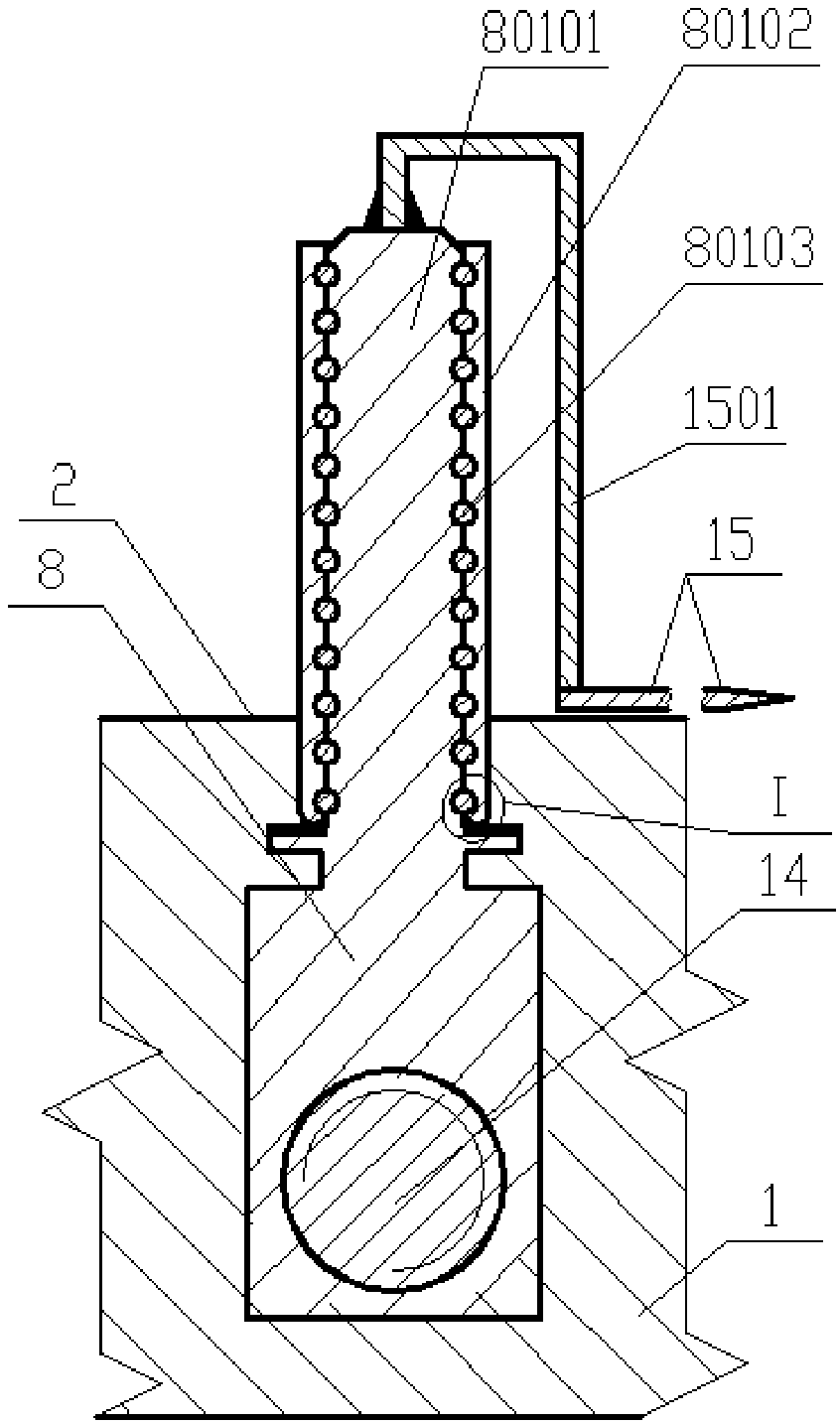

[0020] Such as figure 1 As shown in -5, a kind of laminating equipment includes a base 1 and a plastic roller 3. The upper surface of the base 1 is a laminating table 2. Of course, the laminating table 2 can actually be used as a table by adding a layer of board, considering the cost and structure. For compactness, usually the upper surface of the base 1 is directly used as the glued table top 2 . Two limiting plates 8, a chute 9 and a heating plate 10 are arranged on the glue pressing table 2, and the heating plate 10 is located under the plastic roller 3, and should be flush with the glue pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com