Steel box girder of steel structure bridge

A steel structure and steel box girder technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as lack of support measures for inclined webs and side plates, crimping and damage of inclined webs, and compression deformation during hoisting, and achieve Enhance the overall strength, enhance the strength of the side plate, and prevent the effect of crushing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

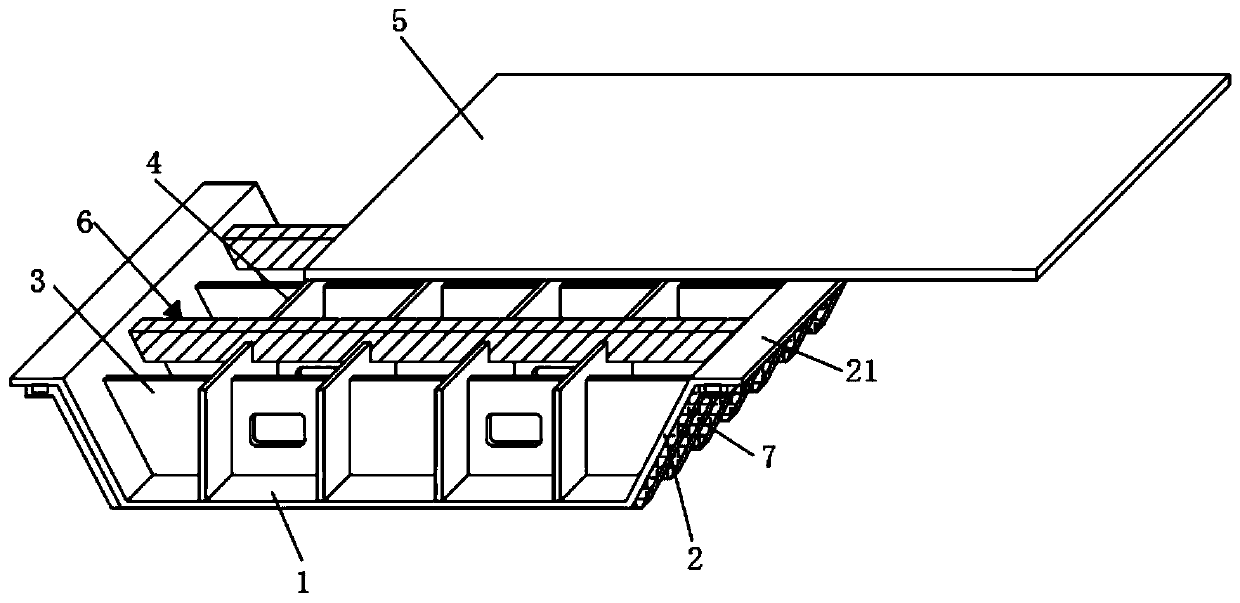

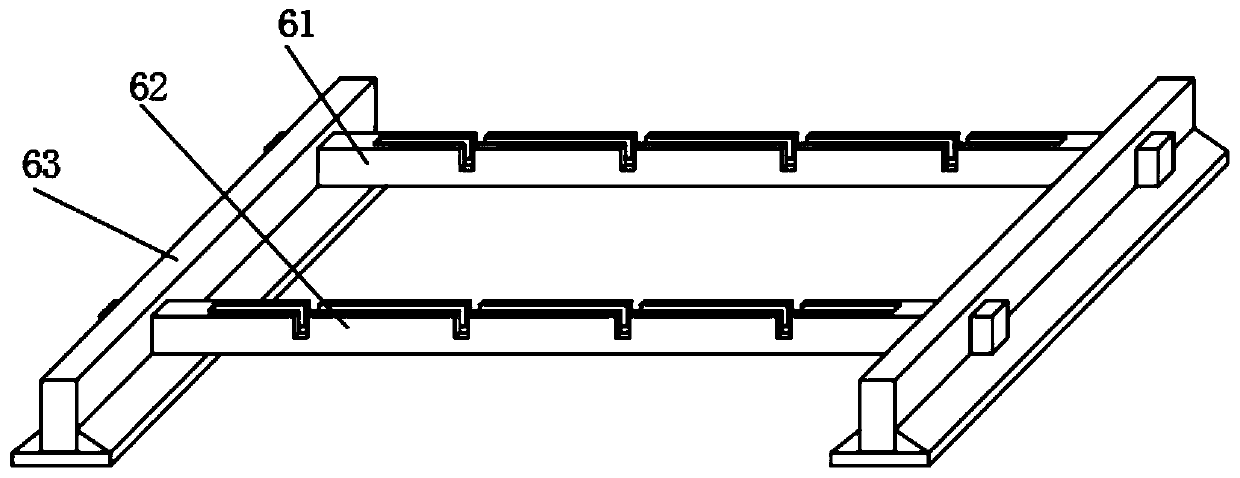

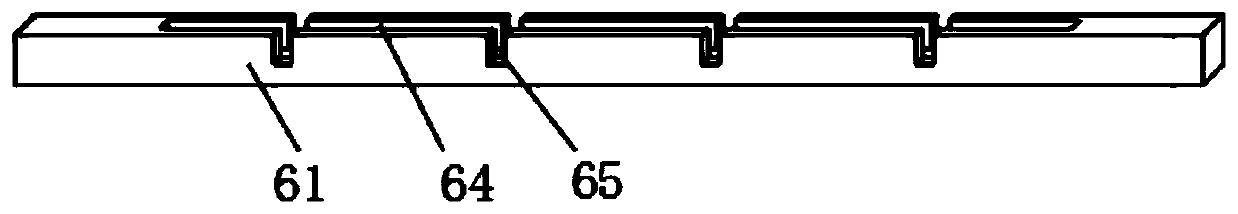

[0037] refer to Figure 1-5 , a steel box girder of a steel structure bridge, comprising: a bottom plate 1, a transverse diaphragm 3, a longitudinal diaphragm 4 and a connecting steel frame assembly 6;

[0038] Both sides of the bottom plate 1 are symmetrically formed with two inclined webs 2, and the tops of the two inclined webs 2 have side plates 21 extending horizontally outwards, and the bottom plate 1 is located between the tops of the two inclined webs 2 A top plate 5 is provided;

[0039] There are multiple transverse diaphragms 3 and longitudinal diaphragms 4. The arrangement of multiple transverse diaphragms 3 can prevent distortion and transverse bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com