Lead screw braking device for vehicle automatic doors

A brake device and automatic door technology, which is applied in the field of rail transit, can solve problems such as reliability limitations, and achieve the effects of stable damping performance, easy adjustment, and simple braking structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

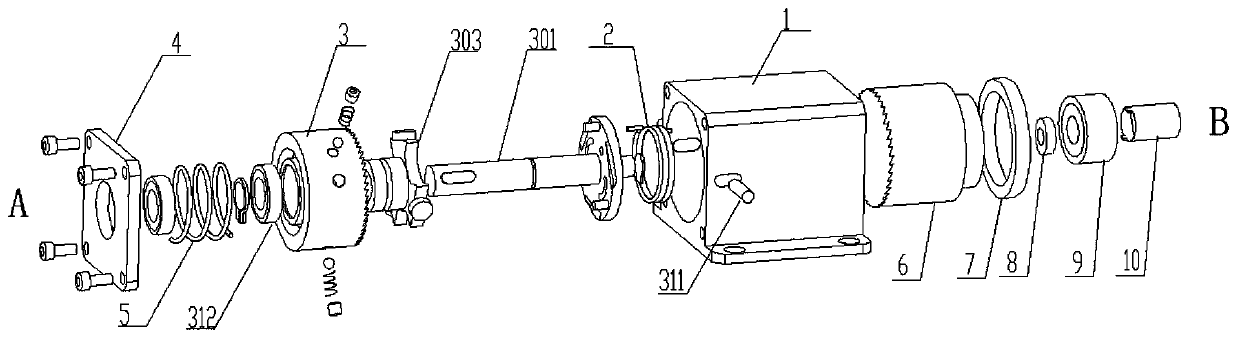

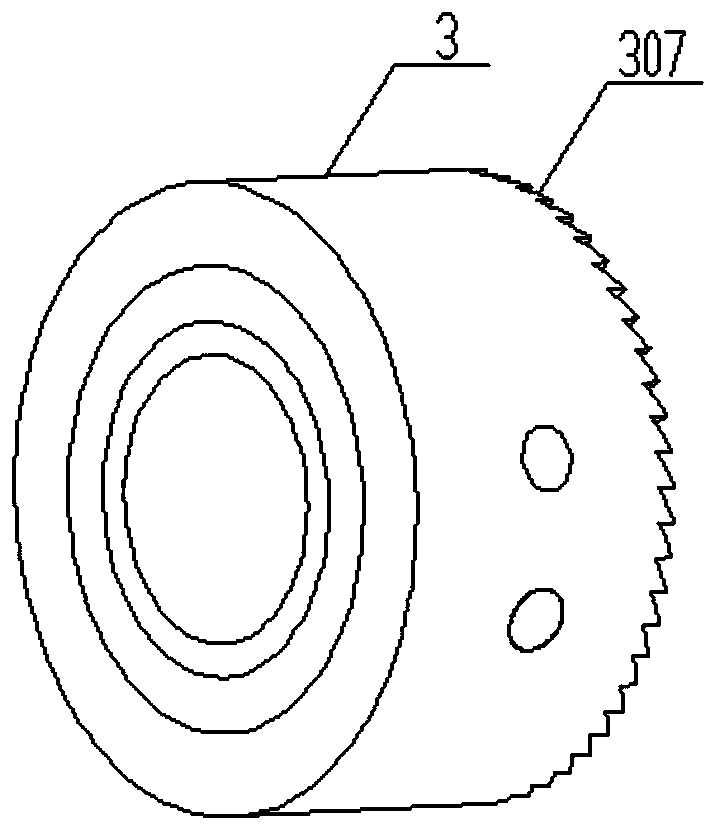

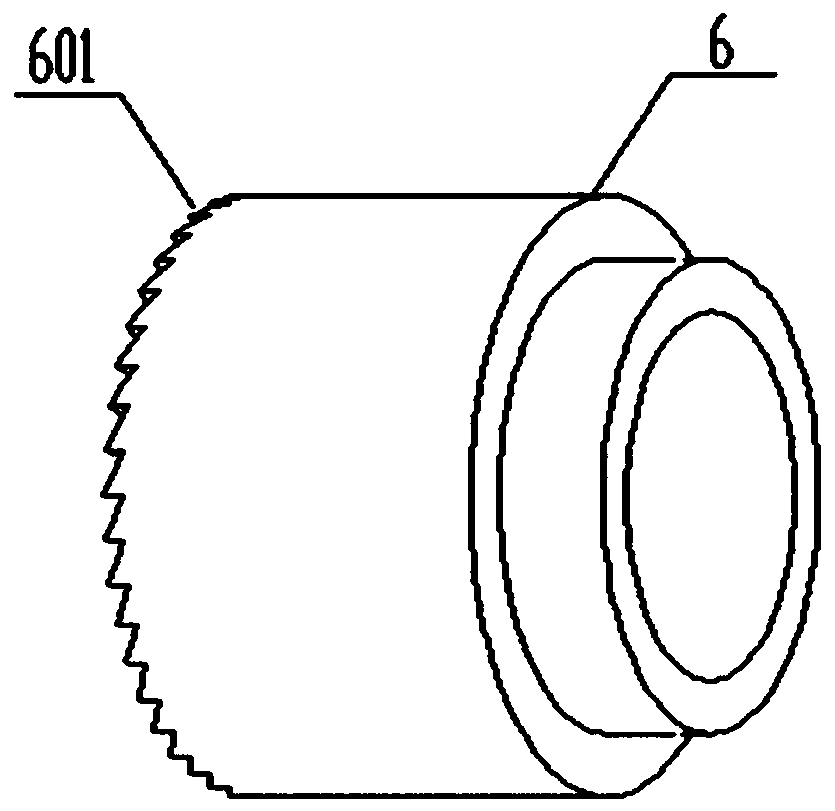

[0034] Such as figure 1 As shown, the screw braking device for automatic doors of vehicles of the present invention includes a driving motor and a screw transmission mechanism. The driving motor and the screw transmission mechanism belong to the prior art and will not be described in detail. A brake box is arranged between the driving motor and the screw transmission mechanism. The brake box includes a brake box 1, a main brake 3, an auxiliary brake 6, an unlocking disc 303 and a transmission main shaft 301, the drive motor, the screw transmission mechanism, The brake boxes are all installed on the fixed frame of the automatic door of the vehicle, and the fixed frame belongs to the prior art, and will not be described in detail.

[0035] Wherein the main brake 3 is installed with the transmission main shaft 301 through the first bearing 312, the auxiliary brake 6 is installed with the brake box 1 through the second bearing 7, and a driving disc 302 is arranged on the transmiss...

Embodiment 2

[0052] This embodiment is an improvement made on the basis of Embodiment 1. For the same content in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description is made here; the disclosure in Embodiment 1 The content should also be taken as the content disclosed in this embodiment.

[0053] Such as figure 1 , in this embodiment, the axial guide mechanism includes two guide rails and sliders installed in the guide rails, the two guide rails are respectively arranged on the inner wall surfaces corresponding to both sides of the brake box body 1, and the shaft of the guide rails and the transmission main shaft 301 The center lines are parallel; the slider is set on the main brake 3, and the two sliders are arranged in axisymmetric manner, and the two sliders are matched with the two guide rails; the spring return mechanism is a compression spring, and the compression spring is set on the transmission spindl...

Embodiment 3

[0055] This embodiment is an improvement made on the basis of Embodiment 1. For the same content in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description is made here; the disclosure in Embodiment 1 The content should also be taken as the content disclosed in this embodiment.

[0056] In this embodiment, the axial guide mechanism includes a long guide hole and a guide pin installed in the long hole. The long guide hole is arranged on the corresponding wall surfaces on both sides of the brake box 1. The long guide hole and the transmission spindle The axis lines of 301 are parallel; the guide pins are arranged on the main brake 3, and the two guide pins are arranged axisymmetrically, and the two guide pins are matched and installed with the two guide slots; one end of the guide pins passes through The thread is installed on the main brake, and the other end extends out of the brake box through the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com