Prefabricated rail top air duct and construction method thereof

A rail-top air duct and roof technology is used in earth-moving drilling, mine/tunnel ventilation, mining equipment, etc. It can solve problems such as difficulty in controlling the accuracy of reserved installation positions, inability to install rail-top air ducts normally, and insufficient connection rigidity. Achieve the effect of improving production quality and efficiency, reducing construction accuracy and reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

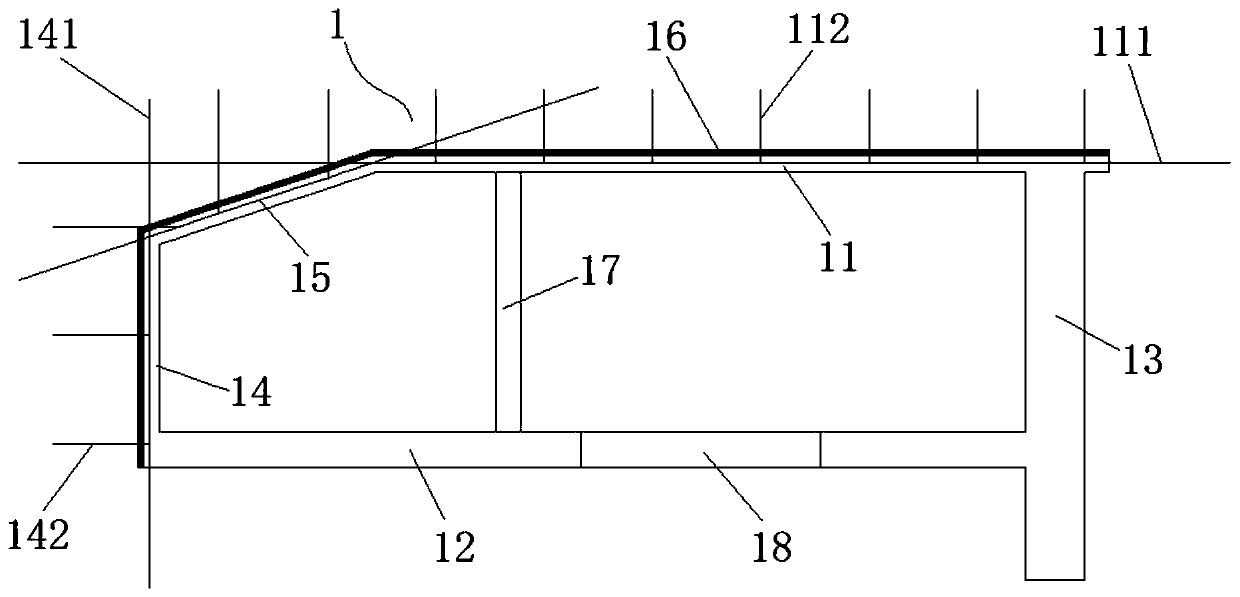

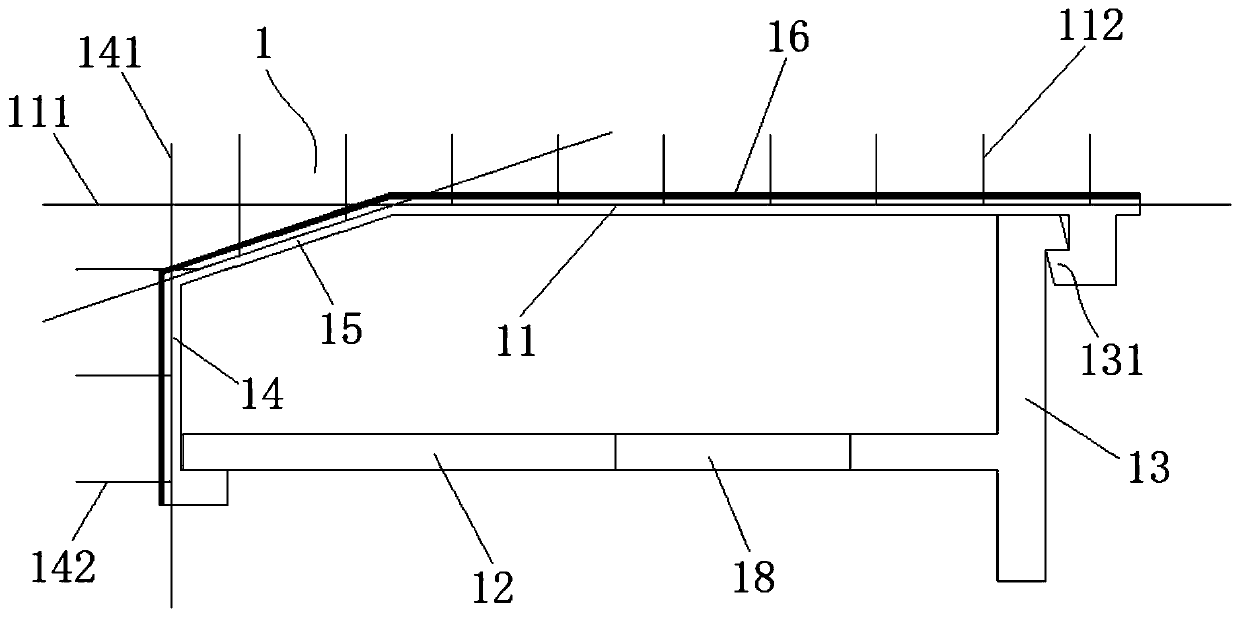

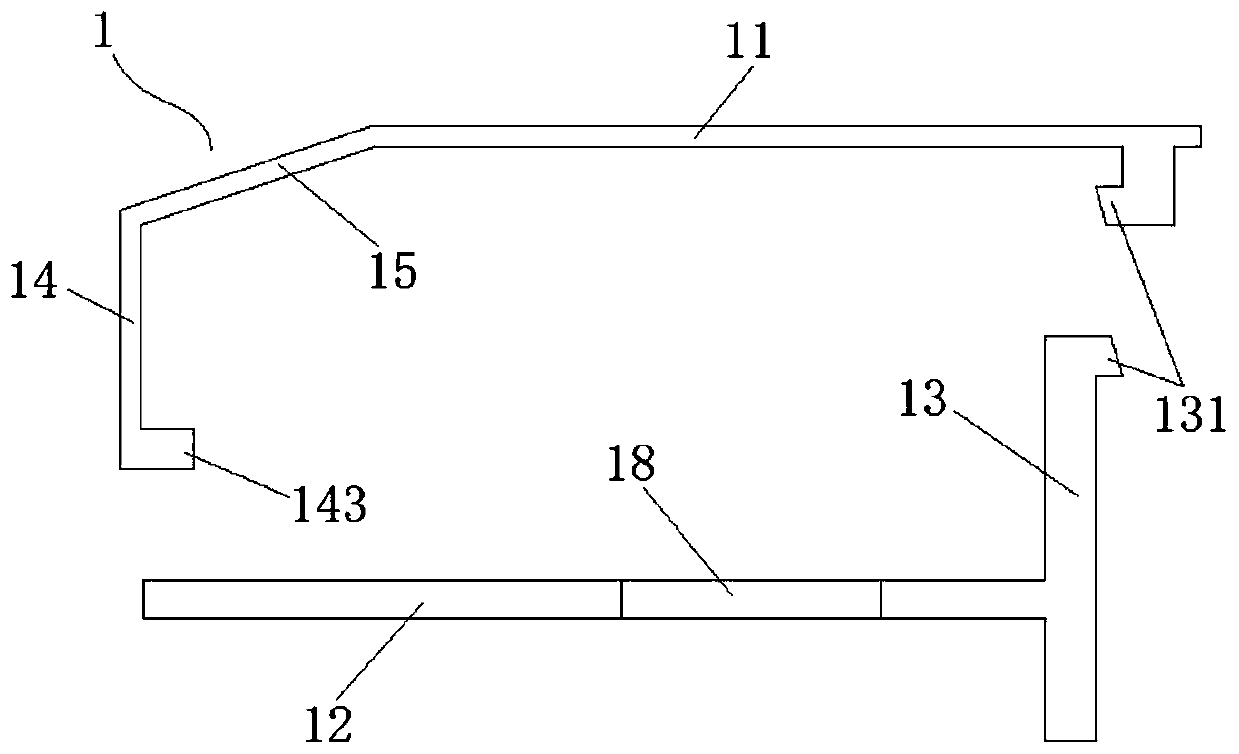

[0048] Such as Figure 1-8 As shown, a prefabricated rail top air duct 1 is provided in this embodiment, mainly including a top plate 11 and a bottom plate 12, the top plate 11 and the bottom plate 12 are arranged parallel to each other, and the same An internal fixed wall 13 is provided at the end. In this embodiment, when the prefabricated rail top air duct 1 is installed, the internal fixed wall 13 is arranged in the middle of the main body 2 of the station; One end is provided with a side plate 14. In this embodiment, when the prefabricated rail top air duct 1 is installed, the side plate 14 is embedded in the pre-casting range of the side wall 22 of the station main body 2.

[0049] Further, an inclined portion 15 is provided at the joint between the top plate 11 and the side plate 14, and the top plate 11, the internal fixed wall 13, the bottom plate 12, the side plate 14 and the inclined portion 15 are sequentially connected; wherein , the outer surfaces of the top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com