Top-down slippage preventing fixing and limiting device

A top-down, limit device technology, applied in the direction of output power conversion device, support structure installation, connecting components, etc., can solve the problems of easy falling off of fasteners, low installation accuracy, poor control, etc., to achieve It is convenient for installation and later maintenance, avoids potential safety hazards, and is convenient for packaging and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

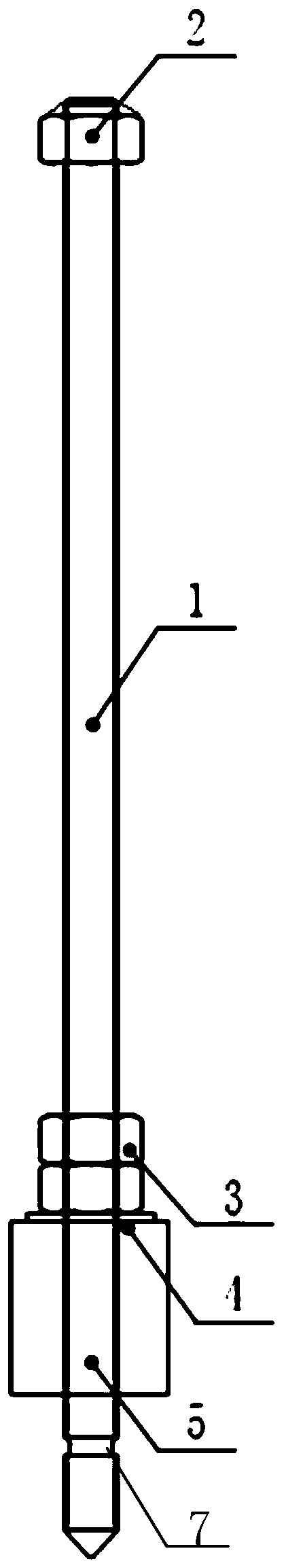

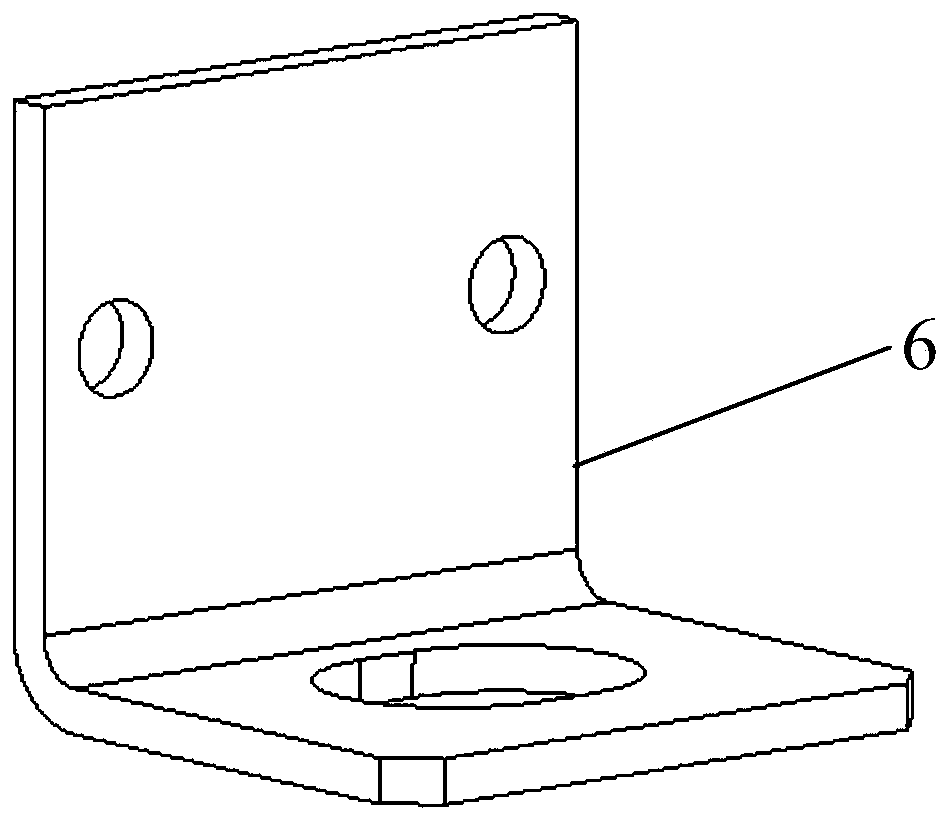

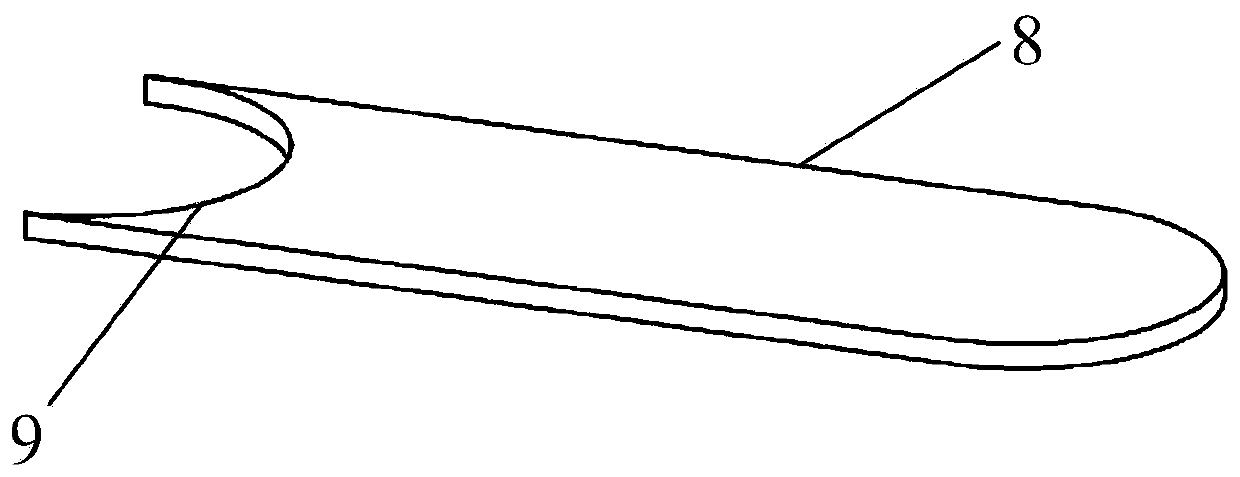

[0030] see Figure 1-3As shown, the present invention provides a top-down anti-slip fixing and limiting device, including a screw assembly installed in the power unit from top to bottom. assembly and disassembly; the screw assembly includes a long screw 1, and the top of the long screw 1 is welded with a nut 2. When the screw assembly is assembled in the power unit, the bottom of the vertical long screw 1 is a positioning piece 6, a self-locking The structure 3 , the spring pad 4 , the support column 5 , and the distance L1 between the top of the self-locking structure 3 and the positioning piece 6 is smaller than the height L2 of the support column 5 .

[0031] Preferably, the nut 2 is a hexagonal nut, and the hexagonal nut is welded to the top of the long screw 1. When installing the power unit to the inverter, the long screw 1 passes through the frame of the power unit from top to bottom and inserts it into the installation hole of the bottom plate of the inverter. Carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com