Waste oil collector

A waste oil collection and piston sleeve technology, applied in the lubrication of machines/engines, shafts, and engines, etc., can solve the problems of large stress on the bearing seal ring, affecting the working efficiency of the fan, and losing the lubrication effect, and achieves extended service life, The high frequency of action and the effect of avoiding the backflow of waste oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

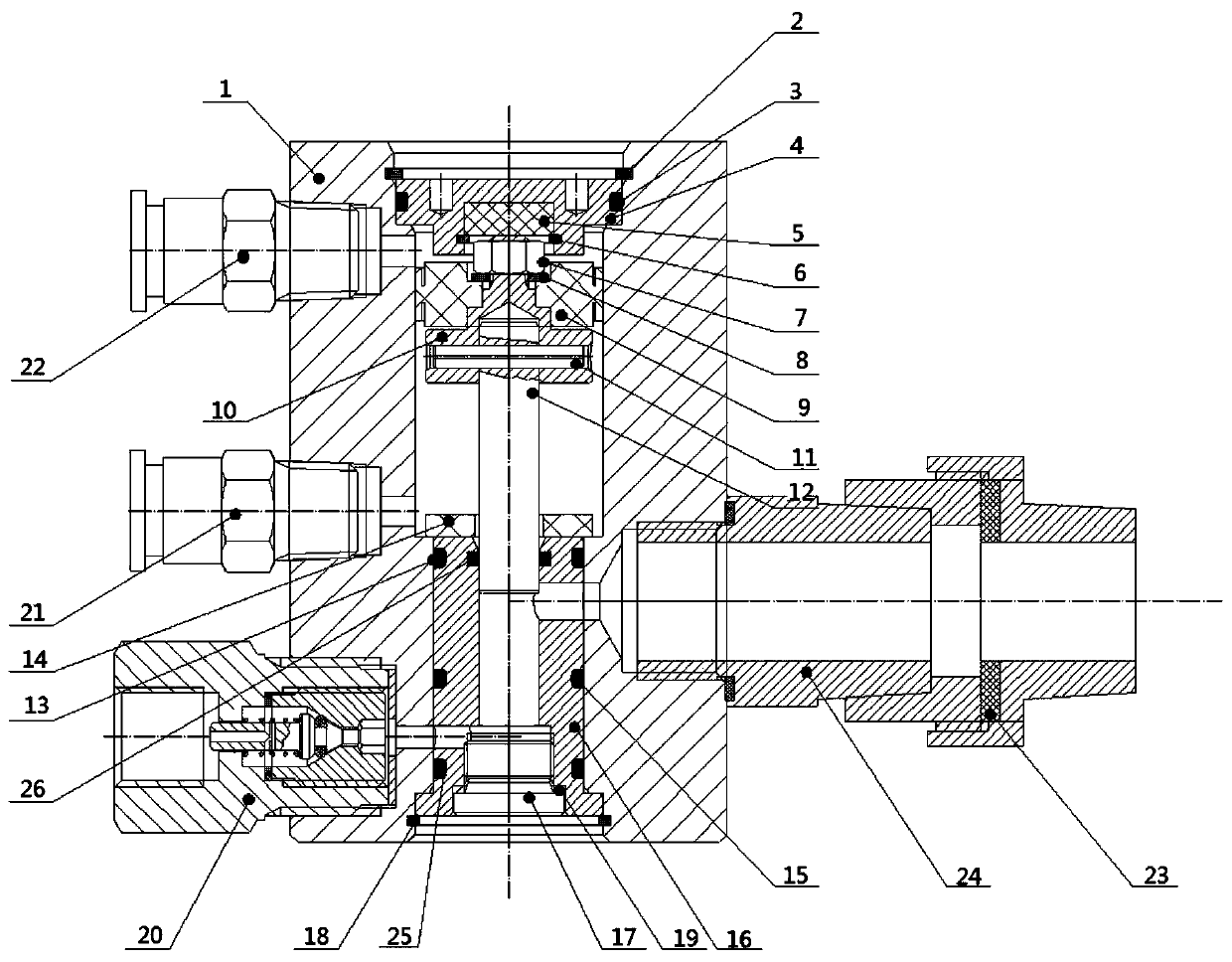

[0018] Such as figure 1 As shown, a waste oil collector includes a housing 1, a piston 12, a piston sleeve 16, a first air pipe joint 21, a second air pipe joint 22 and a one-way valve assembly 20; the piston 12 is arranged on the housing 1, the piston sleeve 16 is arranged on the lower end of the piston 12 and cooperates with it, and the top end of the piston 12 is provided with a cylinder plunger seal 9, so that the cylinder plunger seal 9 moves up and down to form two isolated air Cavity; the left side of the housing 1 is provided with the first air pipe joint 21 and the second air pipe joint 22, the first air pipe joint 21 communicates with the air chamber at the lower end of the cylinder plunger sealing ring 9, The second air pipe joint 22 communicates with the air cavity at the upper end of the cylinder plunger sealing ring 9; The bottom of the casing 1 is connected to the bottom; the right side of the housing 1 is threaded with an adapter assembly 24 , and the adapter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com