ECT sensor calibration method

A calibration method and sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems that affect the accuracy of image reconstruction, time-consuming and labor-consuming, disassembly errors, etc., to avoid errors, high accuracy, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

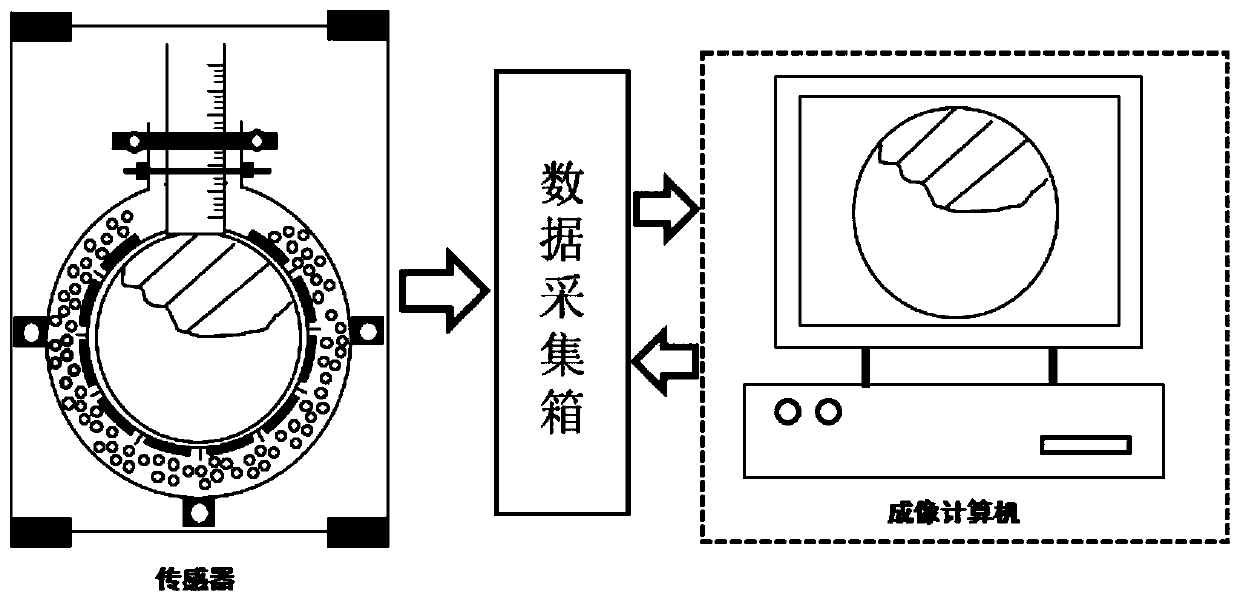

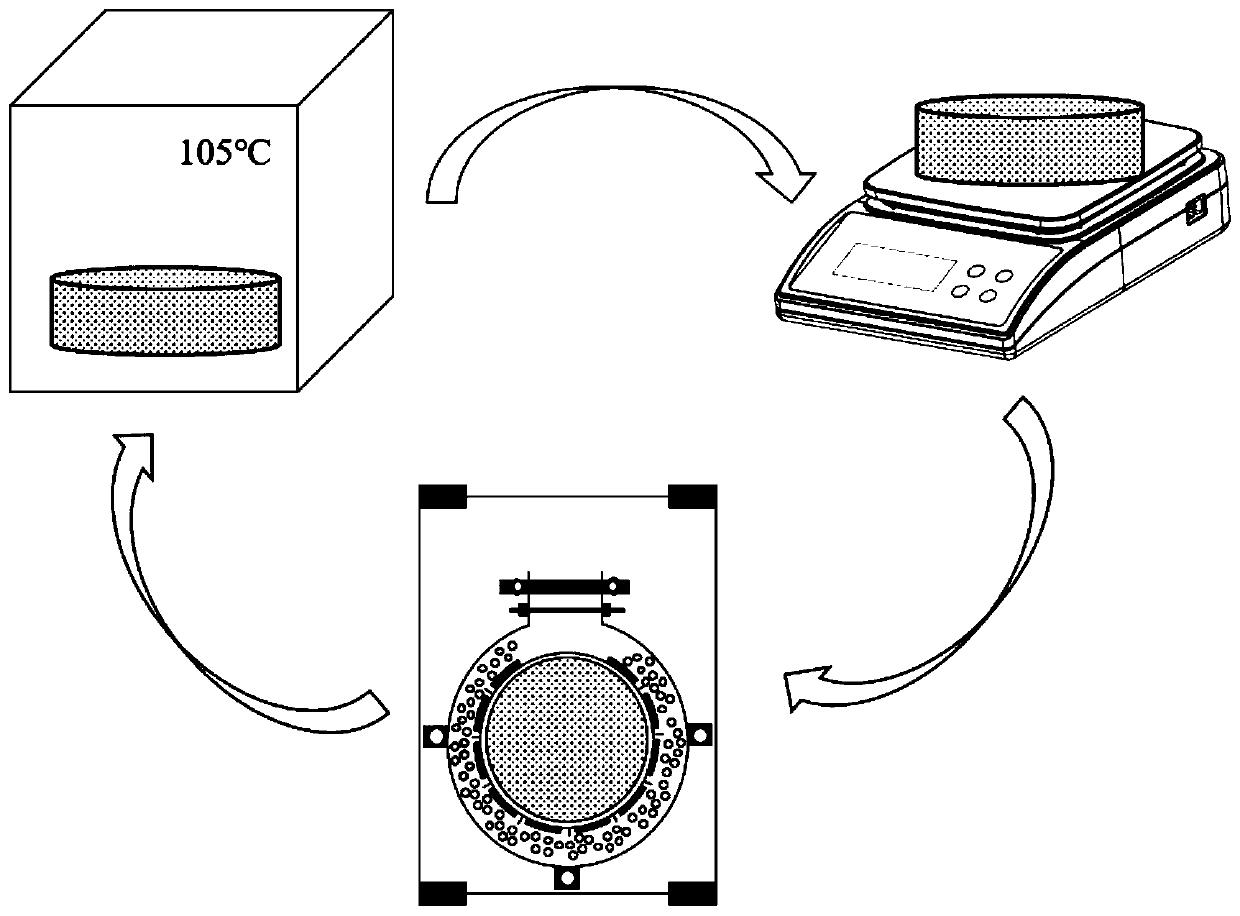

[0024] The specific technical process of the ECT sensor calibration method involved in this embodiment includes five steps in total: preparation of concrete specimens, connection of equipment, preparation work, measurement of capacitance value and normalization process:

[0025] (1) Preparation of concrete specimens: prepare concrete specimens with a diameter of 15 cm and a height of 10 cm, remove the formwork 24 hours after pouring and place it in a standard curing room with a humidity of 95% and a temperature of 20±2°C for 7 After taking it out, cut off 2.5cm symmetrically at both ends to eliminate the impact of the end and rinse it clean, and the remaining 5cm in the middle is used as a test sample;

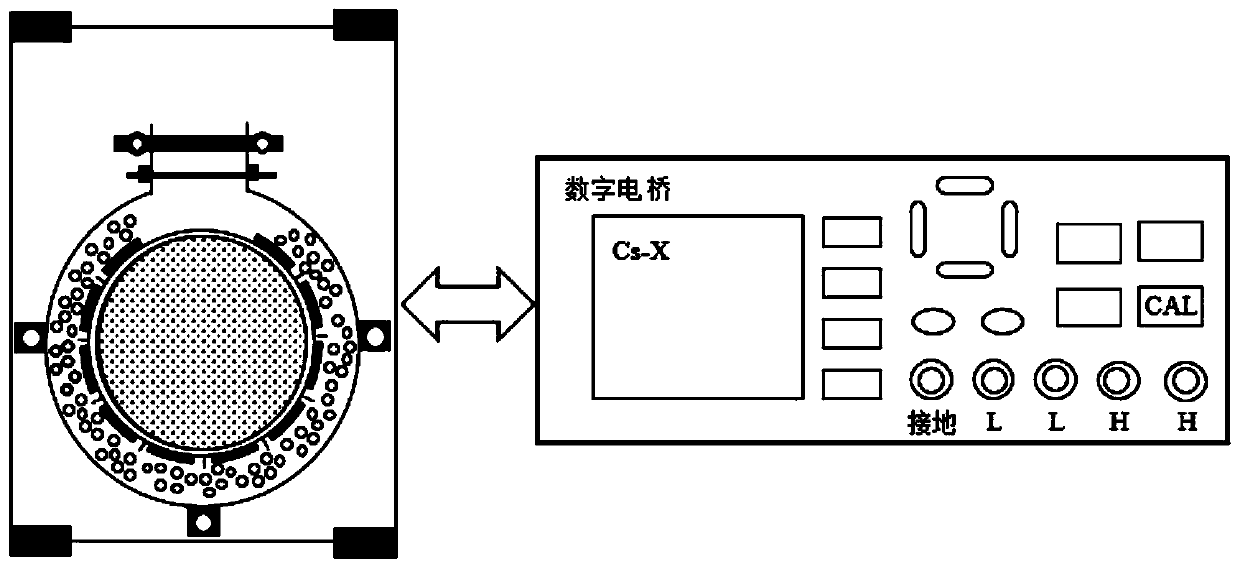

[0026](2) Connecting equipment: take two ECT sensors, one is used as an ECT sensor for offline calibration and connected to the digital bridge, where the excitation electrode is connected to the H port, the detection electrode is connected to the L port, and the other electrode...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap