Bridge internal crack nondestructive testing equipment

A non-destructive testing technology for internal cracks, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as bridge cracks and defects that cannot be detected, and avoid detection Dead angle, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

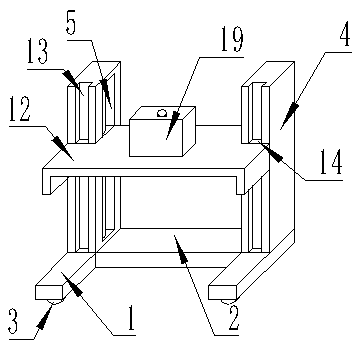

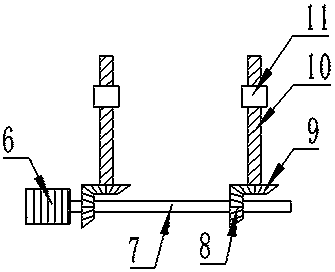

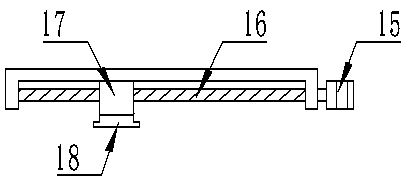

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a non-destructive testing device for internal cracks in bridges. The non-destructive testing device includes two symmetrically arranged support plates 1, and the two support plates 1 are connected by a connecting plate 2. The support plates 1 The bottom of the plate 1 is equipped with a pulley 3; the upper surfaces of the two support plates 1 are fixed with a support column 4, and a height adjustment mechanism is installed between the two support columns 4; the height adjustment mechanism includes a lifting plate 12, and the lifting The bottom of the plate 12 is provided with a translation detection mechanism, and the translation detection mechanism includes an ultrasonic transmitting end 18 .

[0022] The non-destructive testing equipment for cracks inside the bridge uses the ultrasonic transmitter 18 to achieve the purpose of non-destructive testing. It can detect cracks and defects inside the...

Embodiment 2

[0031] Such as figure 1 As shown, in yet another embodiment provided by the present invention, a remote communication module 19 is installed on the upper surface of the lifting plate 12 , and the remote communication module 19 is connected to the ultrasonic transmitting end 18 .

[0032] Ultrasonic waves are transmitted to the bridge through the ultrasonic transmitting end 18, and transmitted to the central processing unit by the remote communication module 19, and the height and position of the transmitted signal are displayed on the display component by the central processing unit, so that the size of the defect can be judged, which is convenient for inspection personnel Intuitively check the defects inside the bridge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com