Method for forming contact groove and semiconductor

A semiconductor and contact layer technology, which is applied to the contact groove formation method and the semiconductor field, can solve the problems of increased time consumption, high cost, and long etching time of contact point through holes, and achieves cost reduction and time consumption, and increased etching. Corrosion time, the effect of ensuring electrical consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

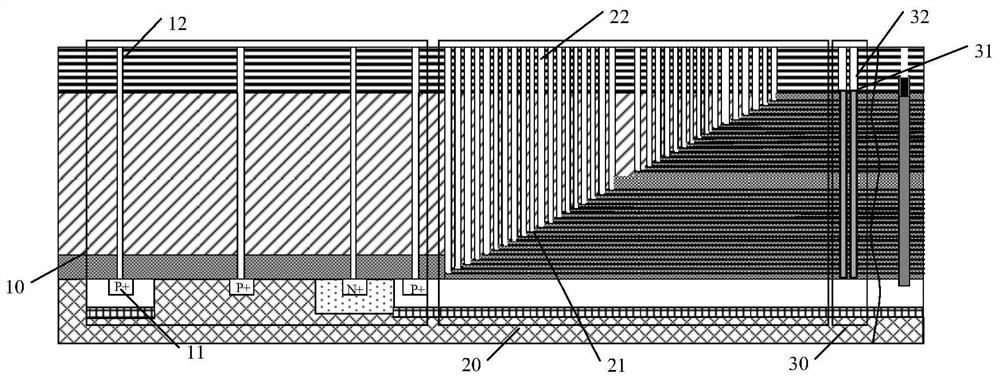

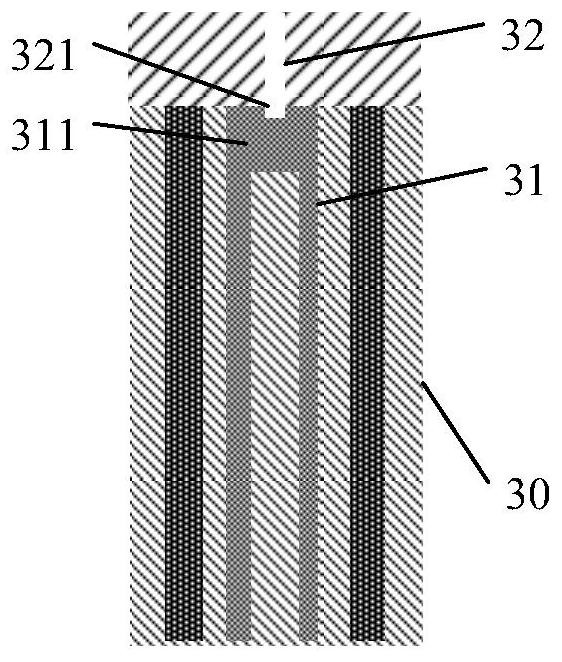

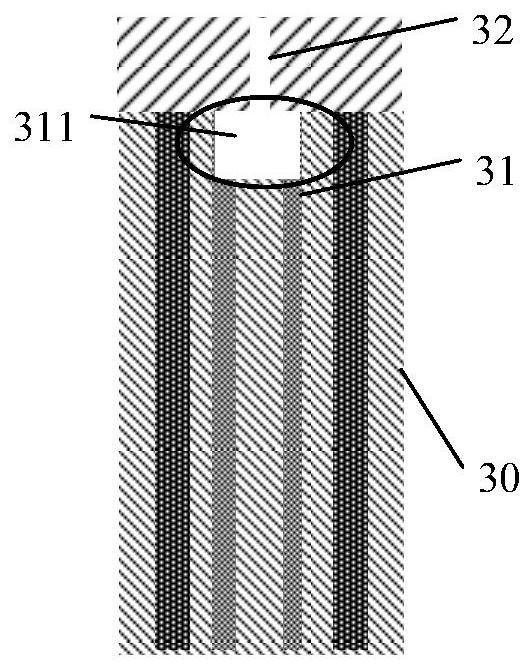

[0033] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution of the application will be further elaborated below in conjunction with the accompanying drawings and embodiments. The described embodiments should not be considered as limiting the application. All other embodiments obtained under the premise of no creative work belong to the scope of protection of this application.

[0034] In the following description, references to "some embodiments" describe a subset of all possible embodiments, but it is understood that "some embodiments" may be the same subset or a different subset of all possible embodiments, and Can be combined with each other without conflict.

[0035] If there is a similar description of "first / second" in the application documents, add the following explanation. In the following description, the terms "first\second\third" are only used to distinguish similar objects and do not mean Regarding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com