Electrical connector and method for manufacturing the same

A technology for electrical connectors and manufacturing methods, which is applied to the components, connections, and assembly/disassembly of contact pieces of connecting devices, and can solve the problems of reducing manufacturing efficiency, reducing signal terminal transmission efficiency, and reducing the shielding performance of electrical connectors, etc. , to achieve the effect of simplifying the forming and cutting steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

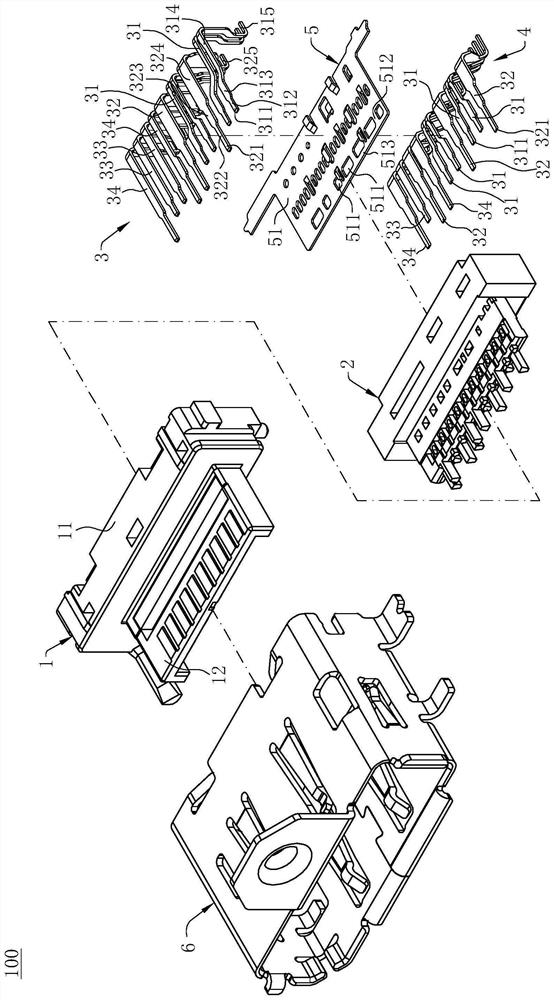

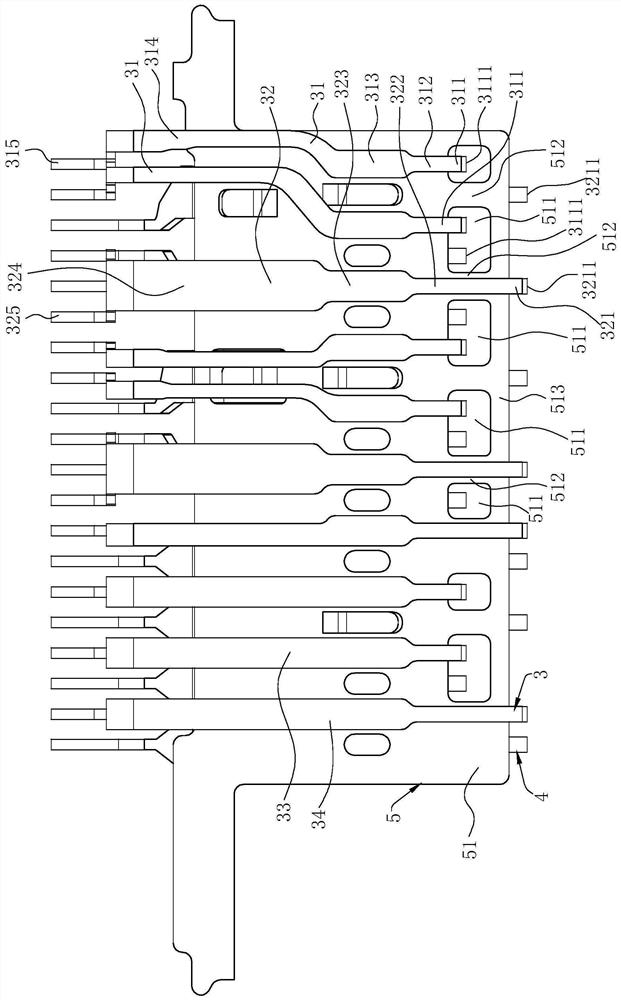

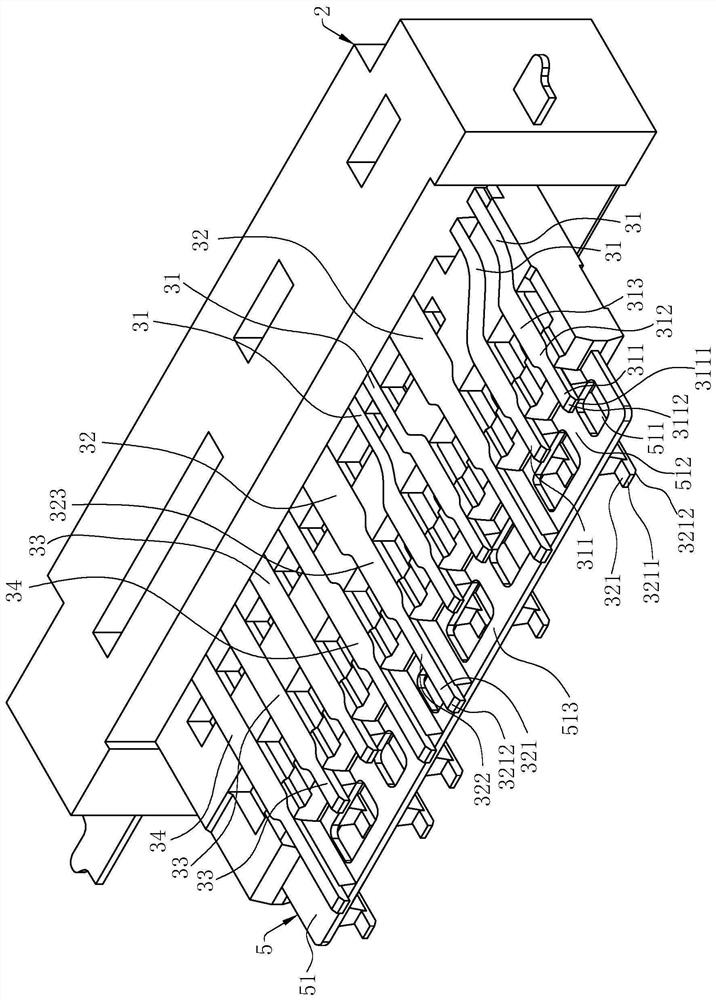

[0032] Such as figure 1 , Figure 4 and Figure 5As shown, this is the electrical connector 100 of the present invention, the electrical connector 100 is a Display Port receptacle for connecting with a Display Port plug (not shown), and the electrical connector 100 is used for Welded to a circuit board (not shown), in other embodiments, the electrical connector 100 can be an HDMI socket or a socket of other interfaces, for docking with an HDMI plug or a plug of other interfaces, the electrical connection The device 100 includes an insulating body 1, an insulator 2 accommodated on the insulating body 1, a first terminal row 3, a second terminal row 4 and a shielding member 5, and a metal shell 6 covers the insulating body 1. The exterior of body 1. Injection molding the insulator 2 on the periphery of the first terminal row 3 , the second terminal row 4 and the shielding member 5 at one time, and then on the first terminal row 3 , the second terminal row 4 , The outer perip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap