Aluminum Profile Extrusion Die with Extrusion Pushback and Blade Anti-Stick Function

A technology for extrusion dies and aluminum profiles, applied in metal extrusion dies and other directions, can solve the problems of inability to use directly, push back and clean the structure by mistake, and have a large impact on automation upgrades, so as to improve reliability and ensure no Simple and reliable effects of damage and switching actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described with reference to the following examples.

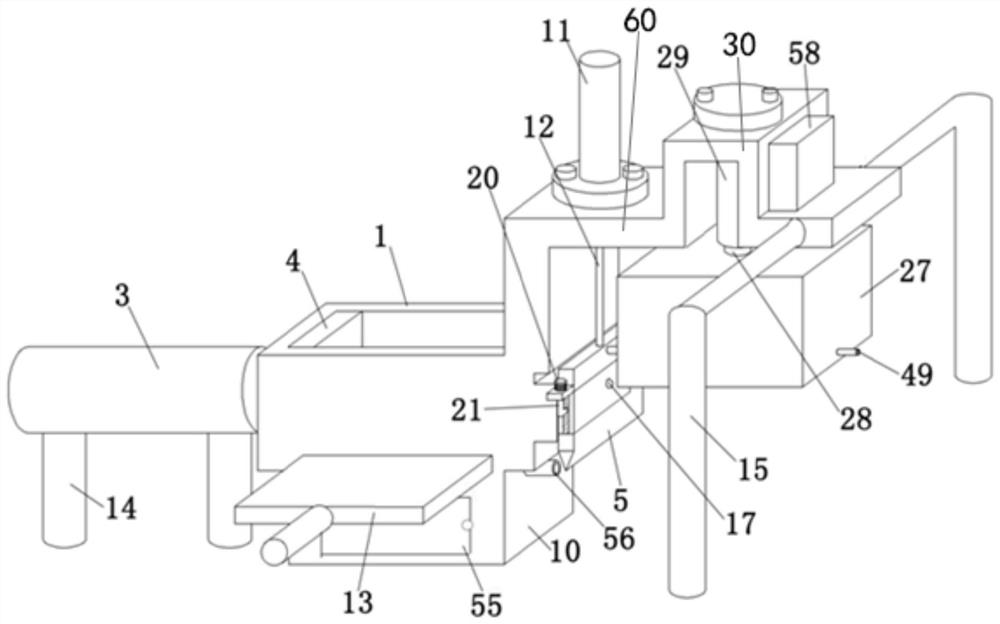

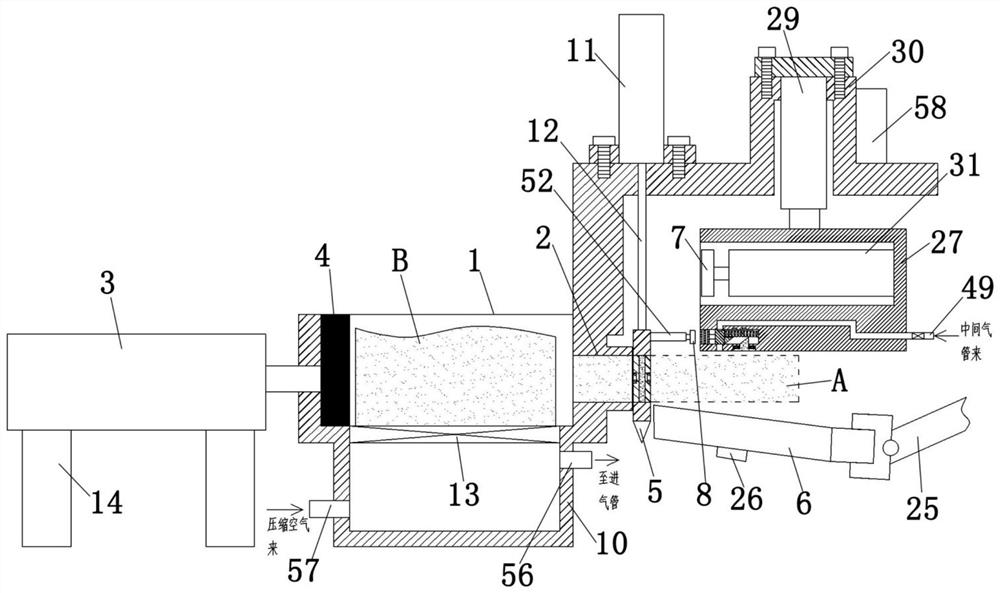

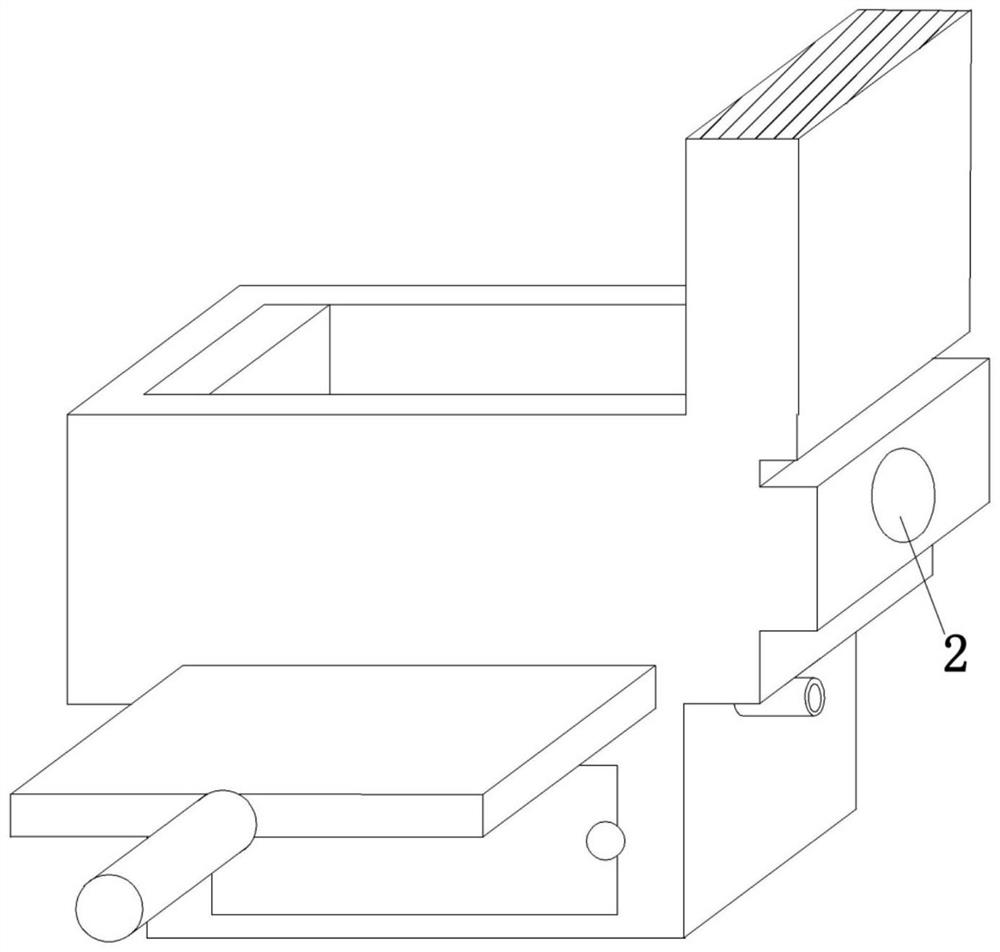

[0030] See eg Figure 1-10 The shown aluminum extrusion die with extrusion channel pushback and blade anti-sticking functions includes a casing 1 connected with an extrusion channel 2 , and the casing 1 has a built-in extrusion plate 4 driven by a first hydraulic cylinder 3 .

[0031] Also includes:

[0032] The aluminum profile cutting mechanism is used to cut the extruded aluminum profile A;

[0033] The aluminum profile sliding judgment mechanism, the inner temperature sensor 16 and the outer temperature sensor 17 are integrated on the blade 5 of the aluminum profile cutting mechanism, and whether the aluminum profile A falls into the receiving plate 6 through the two-level standard of the temperature difference and the gravity sensor 26 of the receiving plate 6 make judgments;

[0034] The extrusion channel push-back cleaning mechanism is used to lower the aluminum profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com