A kind of deposited metal material and preparation method for ultra-low temperature 304l austenitic stainless steel welding

A technology of austenitic stainless steel and deposited metal, applied in the fields of deposited metal material and preparation, and welding material, can solve the problems of reduced ultra-low temperature toughness, reduced ultra-low temperature toughness of deposited metal, waste of resources, etc., and achieves excellent ultra-low temperature toughness, good Economic benefits, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

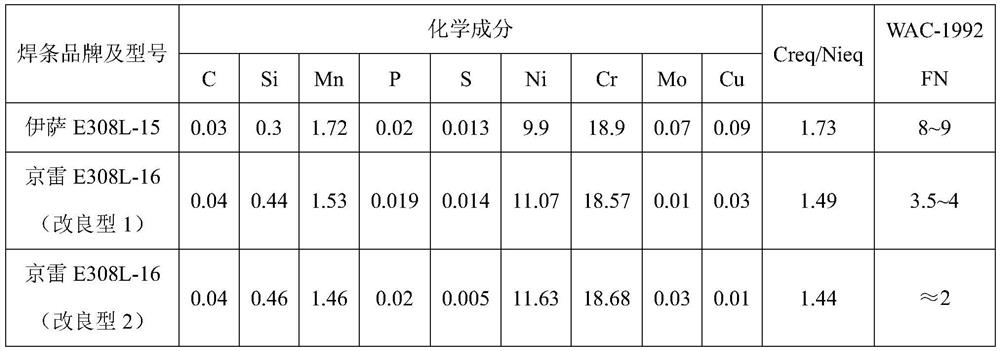

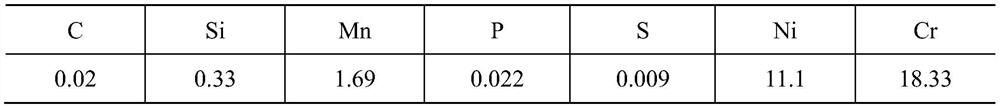

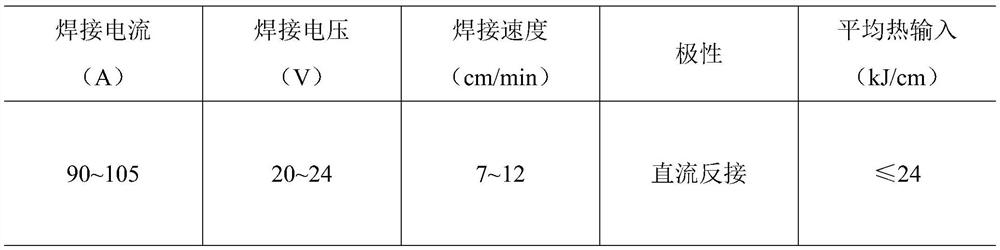

[0026] In this embodiment, three different E308L-XX electrodes are used to weld 304L by arc welding, the welding position is vertical welding, heat treatment is performed at 570°C±10°C×1h after welding, and the diameter of the electrodes is 3.2mm. The brands of the three electrodes, the chemical composition of the deposited metal, and the value of the chromium-nickel equivalent ratio are shown in Table 1, the chemical composition of 304L is shown in Table 2, the welding process parameters are shown in Table 3, and the impact energy of the weld at -196°C is shown in Table 1. 4.

[0027] Comparing Table 1 and Table 4, it can be seen that with the decrease of the chromium-nickel equivalent ratio, the ferrite content in the electrode gradually decreases, and the impact energy of the weld at -196°C gradually increases. When the chromium-nickel equivalent ratio is 1.44, the ferrite content in the weld The body is about 2FN, and the impact energy of the weld at -196°C is 56.7J. It ca...

Embodiment 2

[0037] In this example, three different S F308L FB-S308L submerged arc welding wires and flux combinations are used to weld 304L by submerged arc welding. The welding position is flat welding. After welding, heat treatment is performed at 570°C±10°C×1h, and the diameter of the welding wire is 4.0mm. . The brands of the three submerged arc welding wires and fluxes, the chemical composition of the deposited metal, and the chromium-nickel equivalent ratio are shown in Table 5, the chemical composition of the corresponding flux is shown in Table 6, and the chemical composition of 304L is shown in Table 2 in Example 1 The welding process parameters are shown in Table 7, and the impact energy of the weld at -196 °C is shown in Table 8.

[0038] Comparing Table 5 and Table 8, it can be seen that with the decrease of the chromium-nickel equivalent ratio, the ferrite content in the submerged arc welding wire and the flux deposited metal gradually decreases, and the impact energy of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com