Oil groove iron scrap cleaning device for gear ring processing

A technology for cleaning devices and oil tanks, which is applied in the field of ring gear processing, and can solve problems such as collisions, falling into the oil tank, and falling off of the operator's suction pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

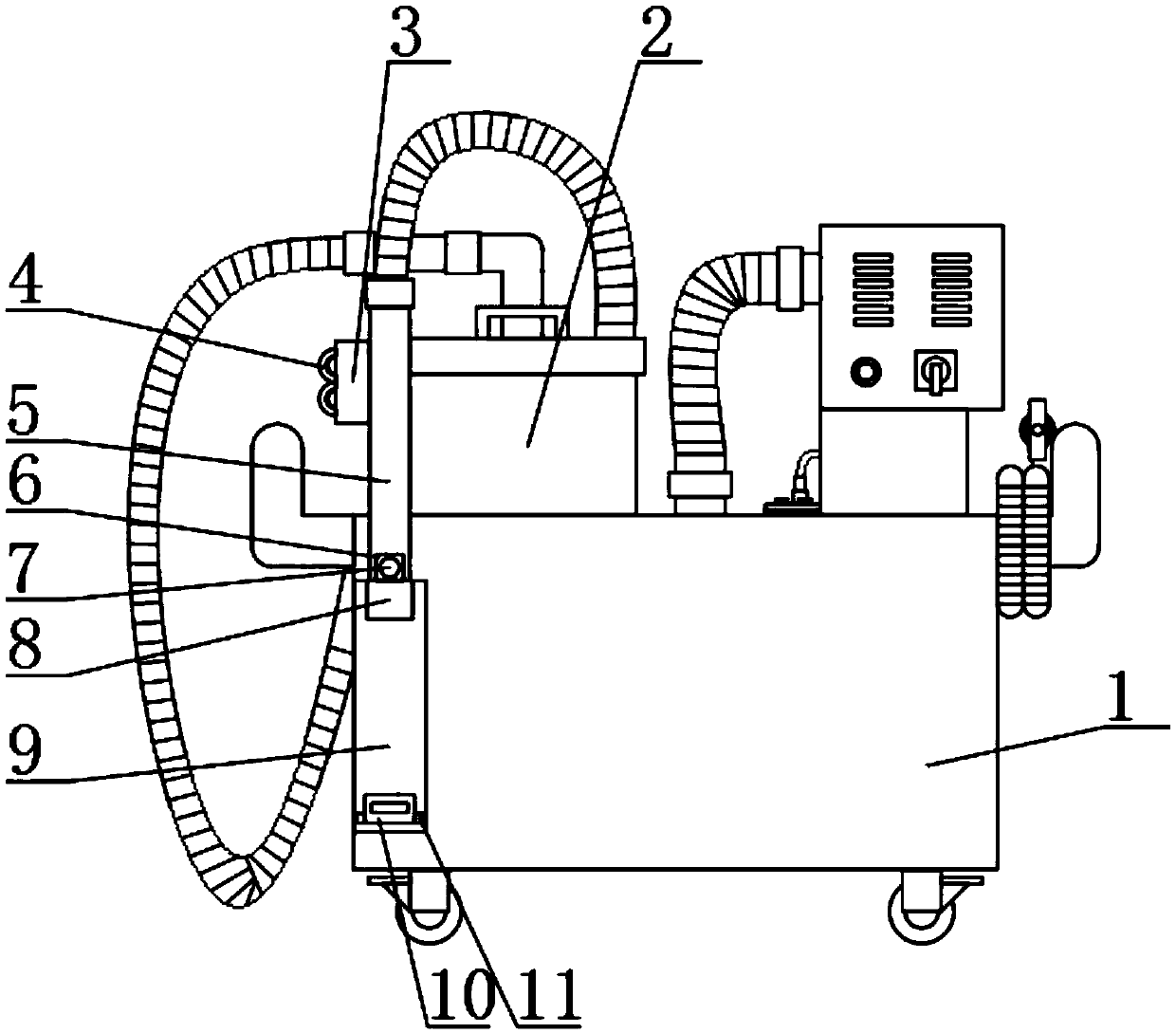

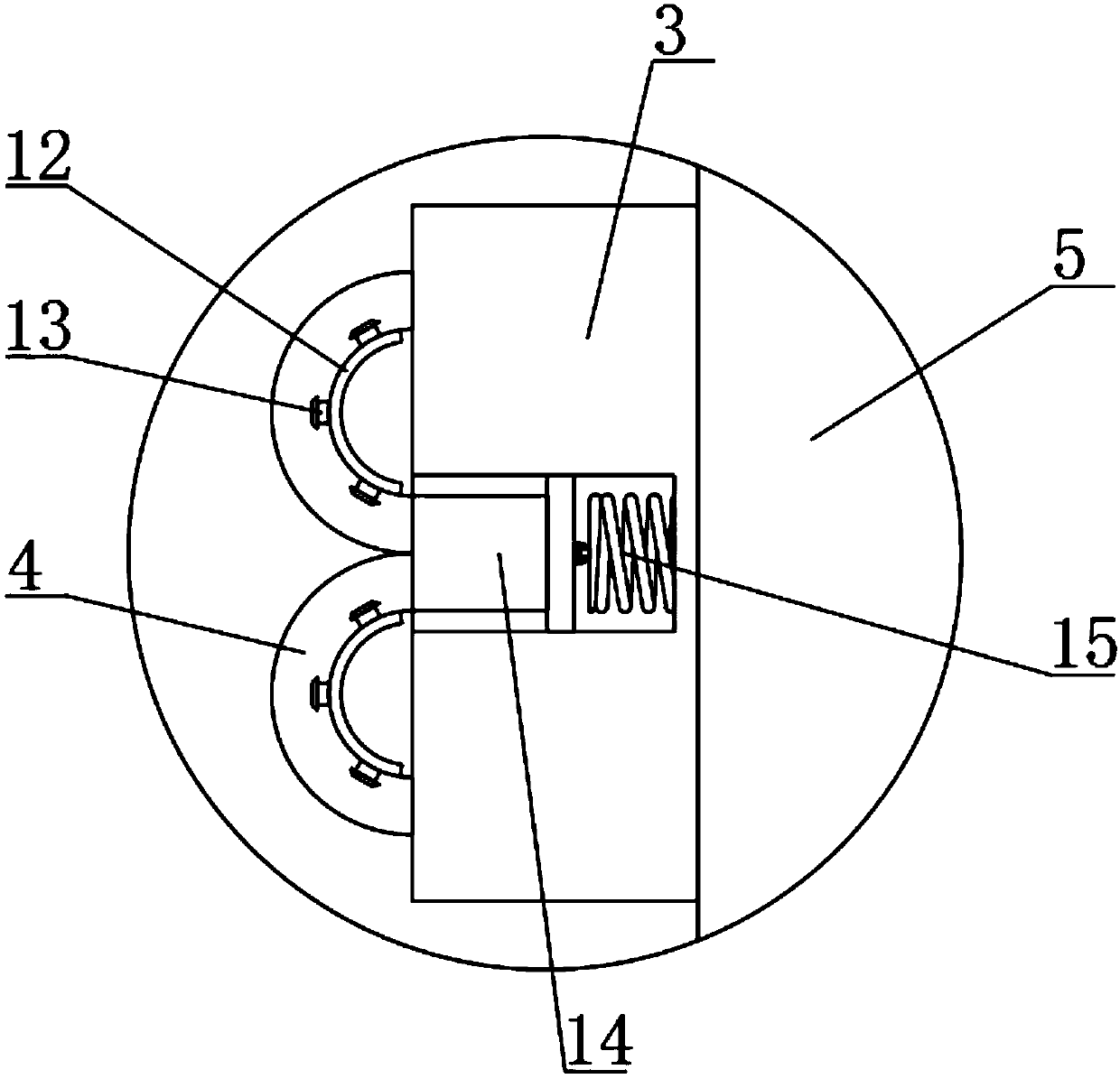

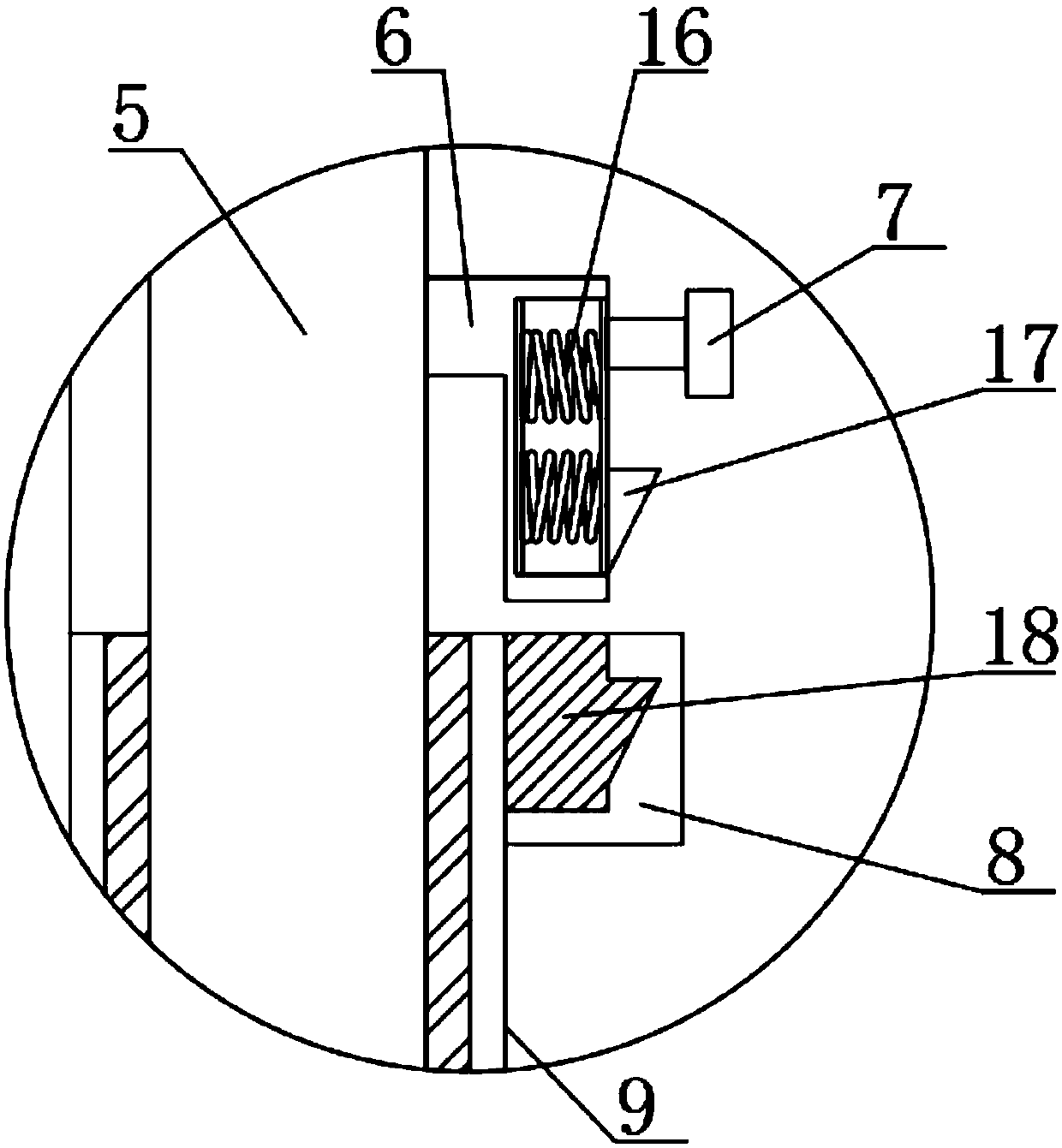

[0024] see Figure 1 to Figure 3 , the present invention provides a technical solution: a device for cleaning iron filings in an oil tank for gear ring processing, including a body 1, a rectangular tube seat 9 is provided on the front surface of the body 1, and a suction tube 5 is provided at the top of the rectangular tube seat 9 , the bottom end of the liquid suction tube 5 is in the inside of the rectangular tube seat 9, and one side surface of the liquid suction tube 5 is provided with an integrated rectangular block 3, and the inside of the rectangular block 3 is provided with a tension spring chamber 15, and the tension spring chamber 15 The top of the telescopic column 14 is connected with a telescopic column 14 by a tension spring, and the top of the telescopic column 14 is symmetrically provided with two integrated arc clamps 4, and the arc clamp 4 is on the outer surface of the rectangular block 3. By setting the arc clamp 4, the The operator can put his fingers insi...

Embodiment 2

[0030] see Figure 1 to Figure 5 , the present invention provides a technical solution: a device for cleaning iron filings in an oil tank for gear ring processing, including a body 1, a rectangular tube seat 9 is provided on the front surface of the body 1, and a suction tube 5 is provided at the top of the rectangular tube seat 9 , the bottom end of the liquid suction tube 5 is in the inside of the rectangular tube seat 9, and one side surface of the liquid suction tube 5 is provided with an integrated rectangular block 3, and the inside of the rectangular block 3 is provided with a tension spring chamber 15, and the tension spring chamber 15 The top of the telescopic column 14 is connected with a telescopic column 14 by a tension spring, and the top of the telescopic column 14 is symmetrically provided with two integrated arc clamps 4, and the arc clamp 4 is on the outer surface of the rectangular block 3. By setting the arc clamp 4, the The operator can put his fingers insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com