Ground self-adaptive AGV chassis and AGV

A self-adaptive, chassis technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of strong self-adaptive ground, good wheel grip, large chassis shaking, etc., to achieve strong self-adaptive ground and wheel grip Good, face adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] An AGV vehicle, which includes a ground-adaptive AGV chassis 10 and a vehicle frame, the vehicle frame is installed on the chassis body 100, wherein the specific structure of the vehicle frame can refer to related technologies, and will not be repeated here.

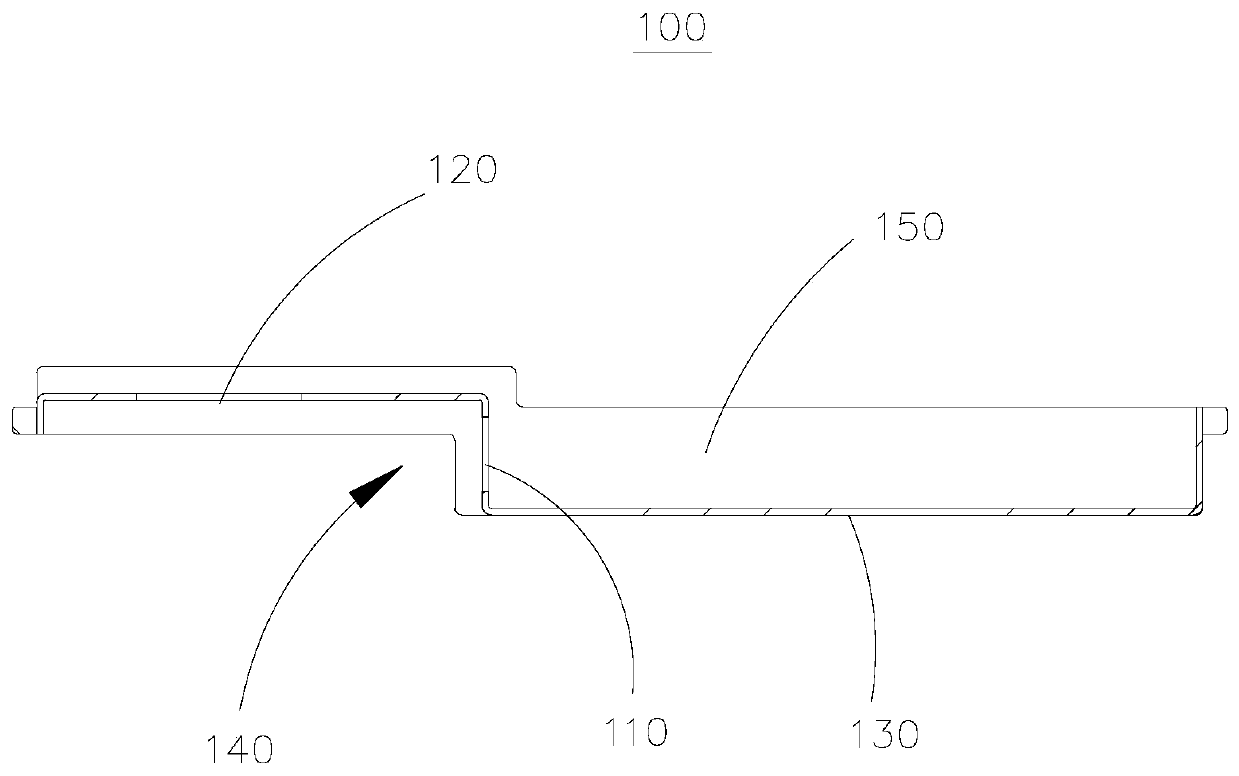

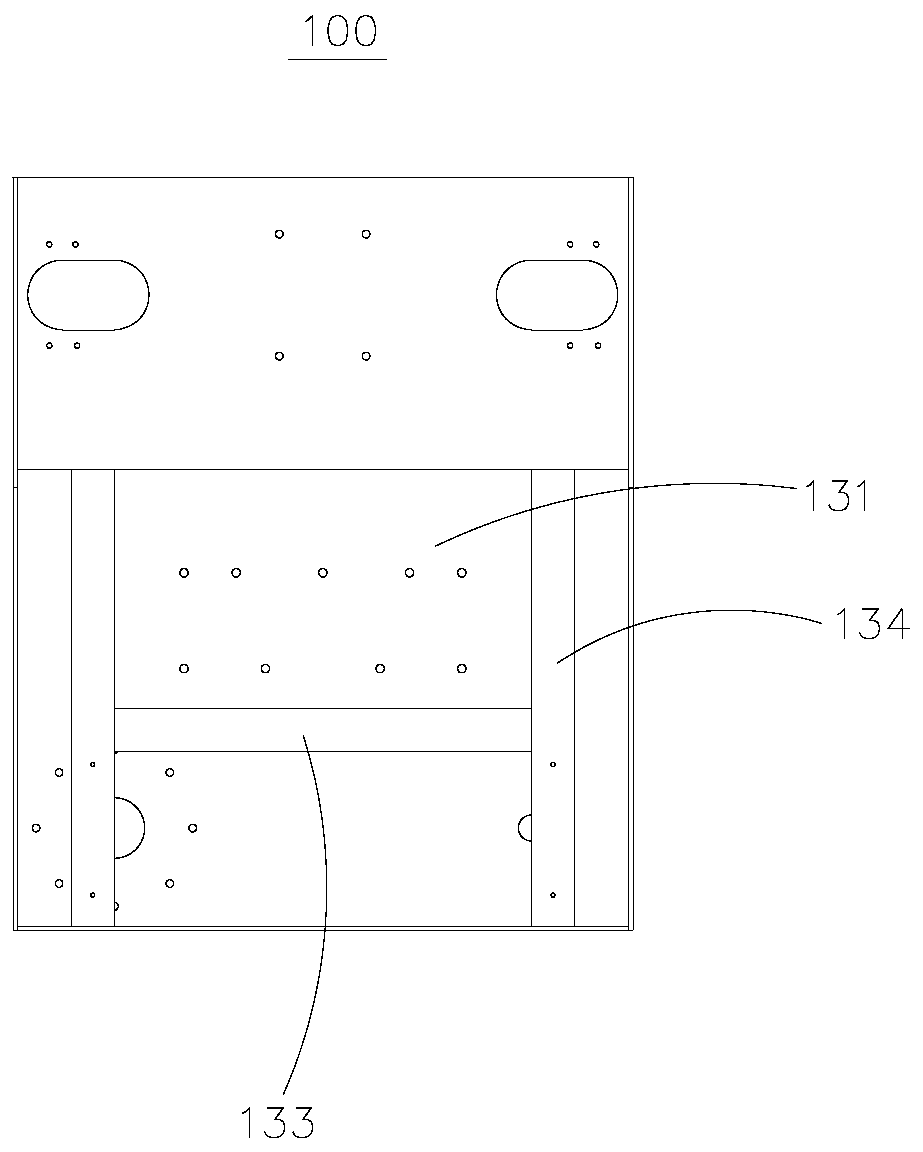

[0046] see figure 1 , the ground adaptive AGV chassis 10 mainly includes a chassis body 100, a wheel set, a rotating plate 300, and an elastic pressure mechanism 400 capable of vertical expansion and contraction.

[0047] Since most of the driving states of the AGV are forward driving, the two ends of the forward running of the chassis body 100 are taken as the front end of the chassis body 100 and the rear end of the chassis body 100 .

[0048] In other embodiments of the present application, the chassis body 100 may be a plane type, but because the existing AGV chassis does not have a tilting prevention and lowering design for the center of gravity of the chassis in order to meet the requirements of overcoming o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com