A kind of austenitic stainless steel and preparation method thereof

A technology for austenitic stainless steel and steel plate, applied in the field of austenitic stainless steel preparation, can solve the problems of increased cost and poor austenite stability, and achieve the effect of low hardness and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

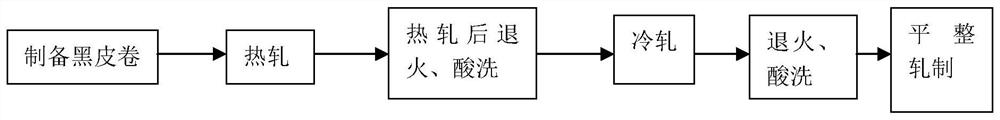

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

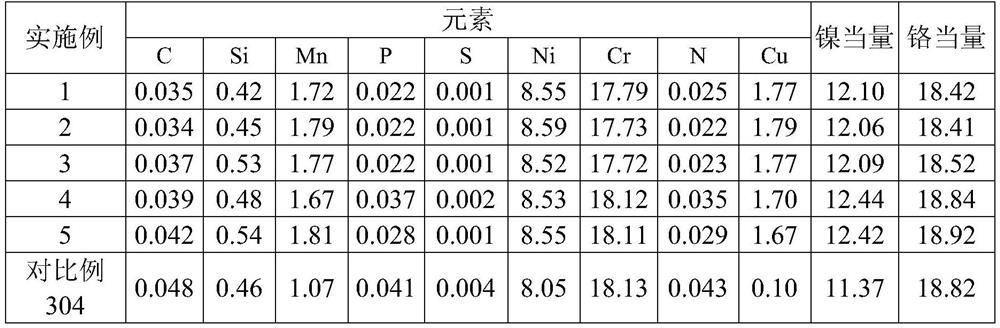

[0037] In terms of mass percentage, the chemical composition of austenitic stainless steel is C: 0.030-0.045%, N: 0.020-0.04%, Ni: 8.50-10.50%, Cu: 1.60-2.00%, Mn: 1.60-2.00%, Cr : 17.00~19.00%, Si: 0.20~0.60%, P: less than or equal to 0.040%, S: less than or equal to 0.015%, the rest is Fe and unavoidable impurity elements; among them, Ni equivalent = Ni+30*(C+N )+0.5*(Mn+Cu); and Cr equivalent=Cr+1.5*Si; in the present embodiment, Ni equivalent value is greater than 12.00, and Cr equivalent value is 17.00~20.00. The chemical composition of 5 embodiments is as follows Table 1 shows.

[0038] The chemical composition of each embodiment of table 1

[0039] Unit: mass%

[0040]

[0041]The composition design of the above five embodiments is controlled in the austenite region of the Cr-Ni equivalent diagram, so that the material has higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com