Inlet/outlet unit of high-strength and corrosion-resistant pump formed by two materials through die pressing

A corrosion-resistant pump and high-strength technology, which is applied to the parts, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of low molding efficiency, troublesome assembly, and corrosion resistance, and achieve high molding efficiency. , The connection fastness is strong, and the effect of satisfying the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

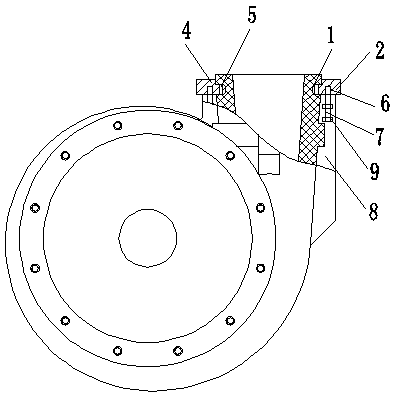

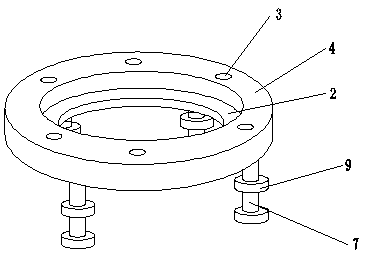

[0021] Embodiment 1: as figure 1 , 2 As shown, the inlet and outlet of a high-strength corrosion-resistant pump molded from two materials, the nozzle of the pump is made of plastic material, the nozzle is the inlet and / or outlet, and there is a ring groove on the outside of the nozzle 1 , A metal flange 2 is arranged in the annular groove 1, and the material of the metal flange 2 is iron or stainless steel. The metal flange 2 is partially located in the annular groove 1, and partially located outside the annular groove 1. The area where the metal flange 2 is located in the annular groove 1 is provided with a number of through holes 5, and the through holes 5 are along the circumferential direction of the metal flange 2. Evenly spaced. The area outside the annular groove 1 is provided with several flange holes 3, and the metal flange 2 and the nozzle are molded. The metal flange 2 is provided with an annular protrusion 4 on one side of the free end of the nozzle, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com