Connector of automotive air conditioning pipeline

A technology for automotive air conditioners and connectors, which is applied in the direction of sleeve/socket connections, pipes/pipe joints/fittings, vehicle parts, etc. It can solve the problem that the end face gasket loses the sealing through hole to form a seal, cannot realize the seal, and increases the production of the seal shaft cost and other issues, to achieve the effect of reliability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

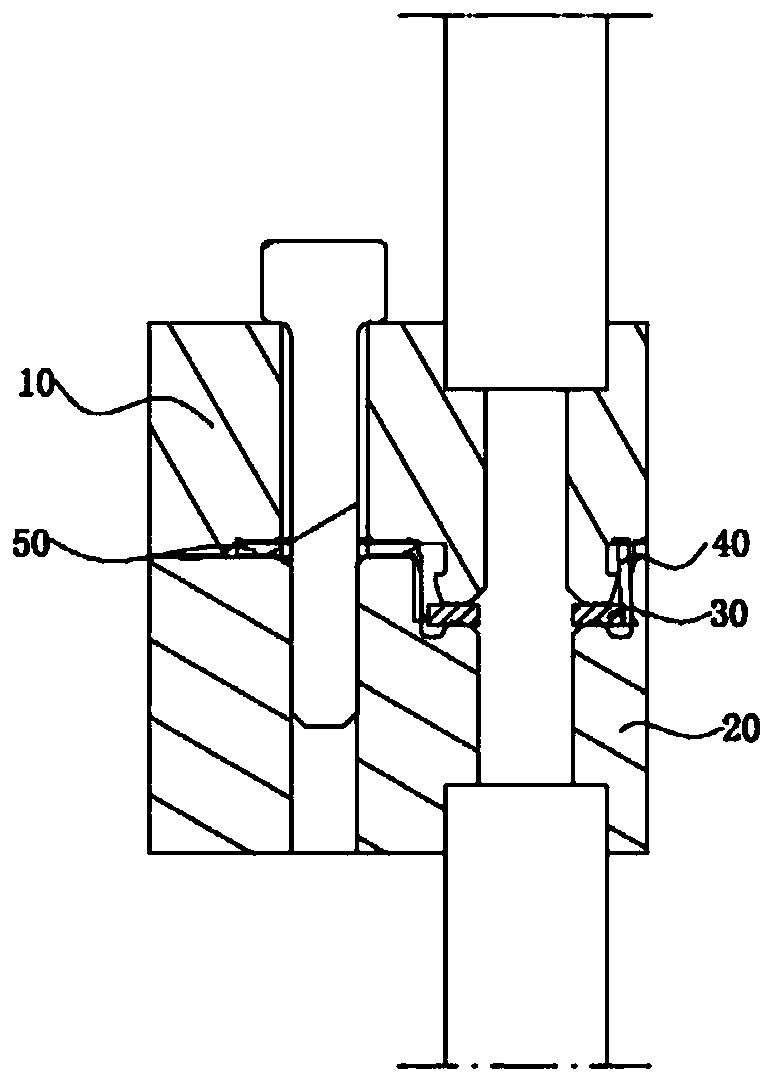

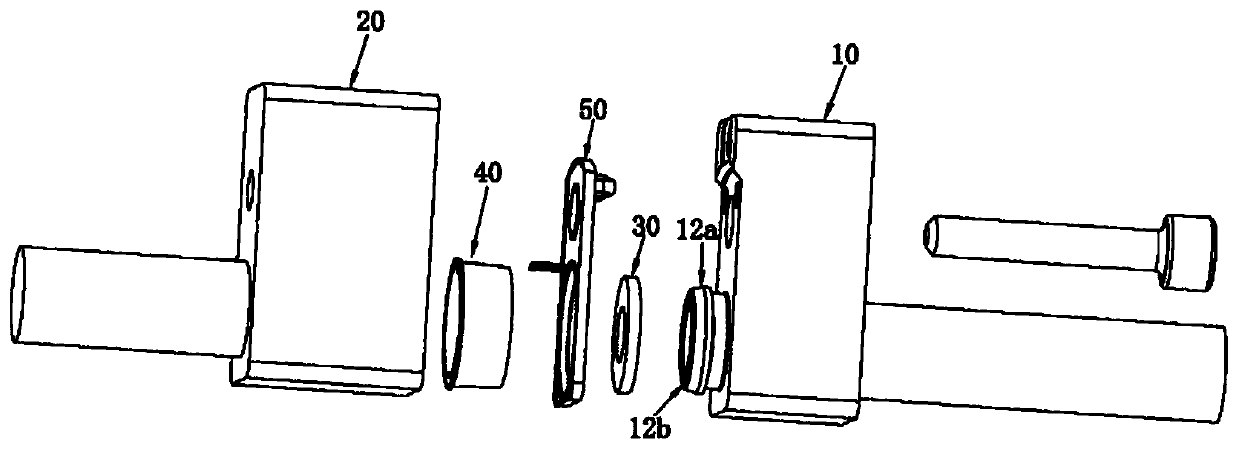

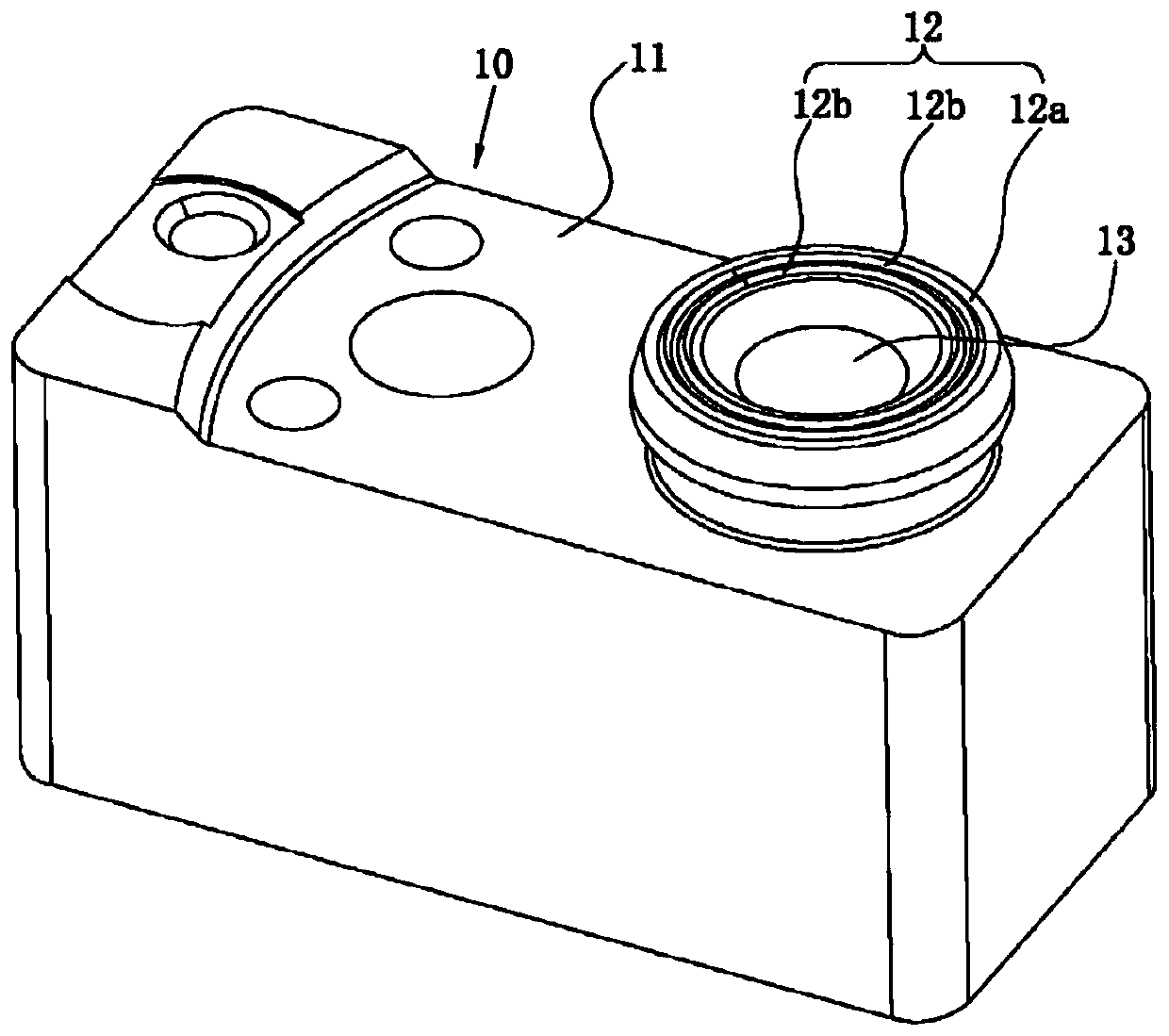

[0057] Such as Figure 1 to Figure 9 , the connector of the first automobile air-conditioning pipeline of the present invention includes a first pipe joint 10, a second pipe joint 20, and a metal sealing member 30. Each part and the relationship between each part are described in detail below:

[0058] The first pipe joint 10 includes a first body 11 and a first annular piercing part 12. The first body 11 is provided with a first through hole 13 passing through the first body 11. One end of the first annular piercing part 12 Fixed with the first body 11 , the first annular piercing member 12 surrounds the opening of the first through hole 13 .

[0059] The preferred structure of the first annular piercing part 12 is: comprising a mounting seat 12a, a first annular protrusion 12b, one end of the mounting seat 12a is fixed to the first body 11, and the mounting seat 12a surrounds the hole in the first through hole 13 Around the opening, the mounting seat 12a is provided with a ...

Embodiment 2

[0084] Such as Figure 10 , the connector of the third automobile air-conditioning pipeline of the present invention includes a first pipe joint 10, a second pipe joint 20, and a metal sealing member 30. The first pipe joint 10 includes a first body 11, a support 14, and a first pipe joint 10. The main body 11 is provided with a first through hole 13 passing through the first main body, one end of the support 14 is fixed to the first main body 11, and the support 14 surrounds the opening of the first through hole 13;

[0085]The second pipe joint 20 includes a second body 21 and a second annular piercing part 22. The second body 21 is provided with a second through hole 23 passing through the second body 21. One end of the second annular piercing part 22 Fixed with the second body 21, the second annular penetrating part 22 surrounds the opening of the second through hole 23;

[0086] One end of the metal sealing part 30 is sleeved on the support 14 and is interference fit wit...

Embodiment 3

[0096] Such as Figure 11 with 12 , the connector of the third automobile air-conditioning pipeline of the present invention includes a first pipe joint 10, a second pipe joint 20, and a metal sealing member 30. The first pipe joint 10 includes a first body 11, and the first body 11 is provided with There is a first through hole 13 penetrating through the first body. The second pipe joint 20 includes a second body 21 , and the second body 21 is provided with a second through hole 23 passing through the second body 21 .

[0097] Metal sealing part 30 comprises annular carrier 31, the 3rd annular piercing part 32, the 4th annular piercing part 33, the 3rd annular piercing part 32 is arranged on one end of annular carrier 31, the 4th annular piercing part 33 is disposed at the other end of the ring carrier 31 .

[0098] One end of the metal sealing part 30 surrounds the opening of the first through hole 13, and the other end of the metal sealing part 30 surrounds the opening o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap