Sphere roundness and diameter detection device and method for probe of coordinate measuring machine

A coordinate measuring machine and coordinate measuring technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the real situation cannot be explained, and the calibration of the coordinate measuring machine probe cannot provide accurate data, etc., so as to improve the measurement efficiency, the measurement method is simple, The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

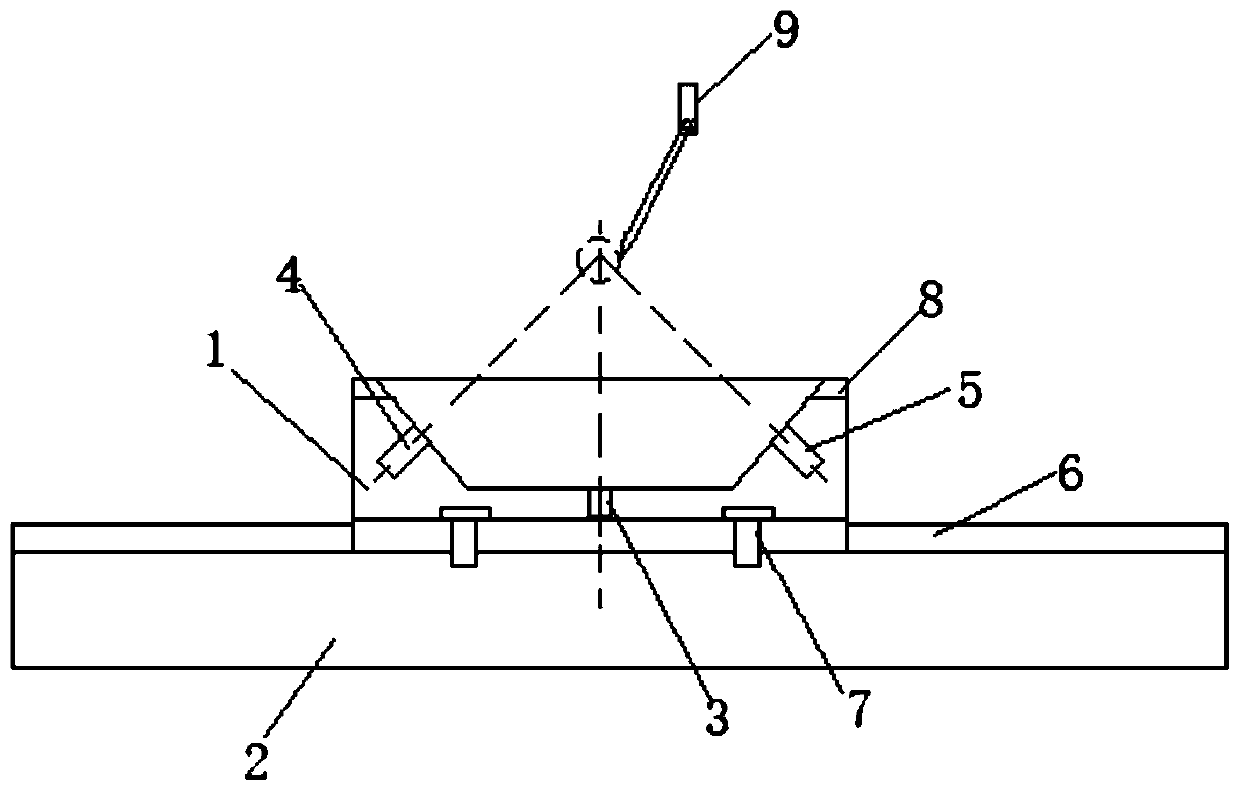

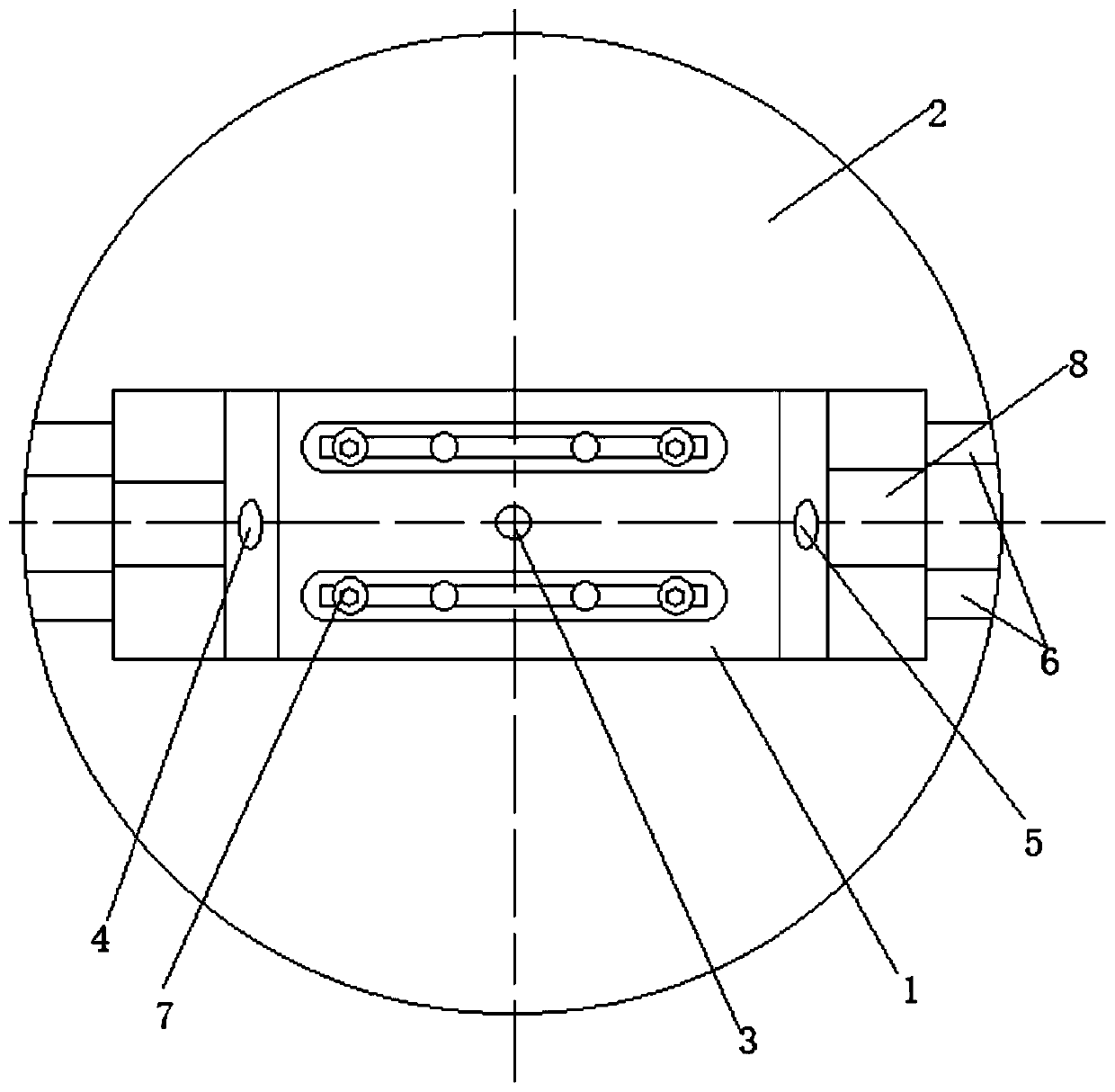

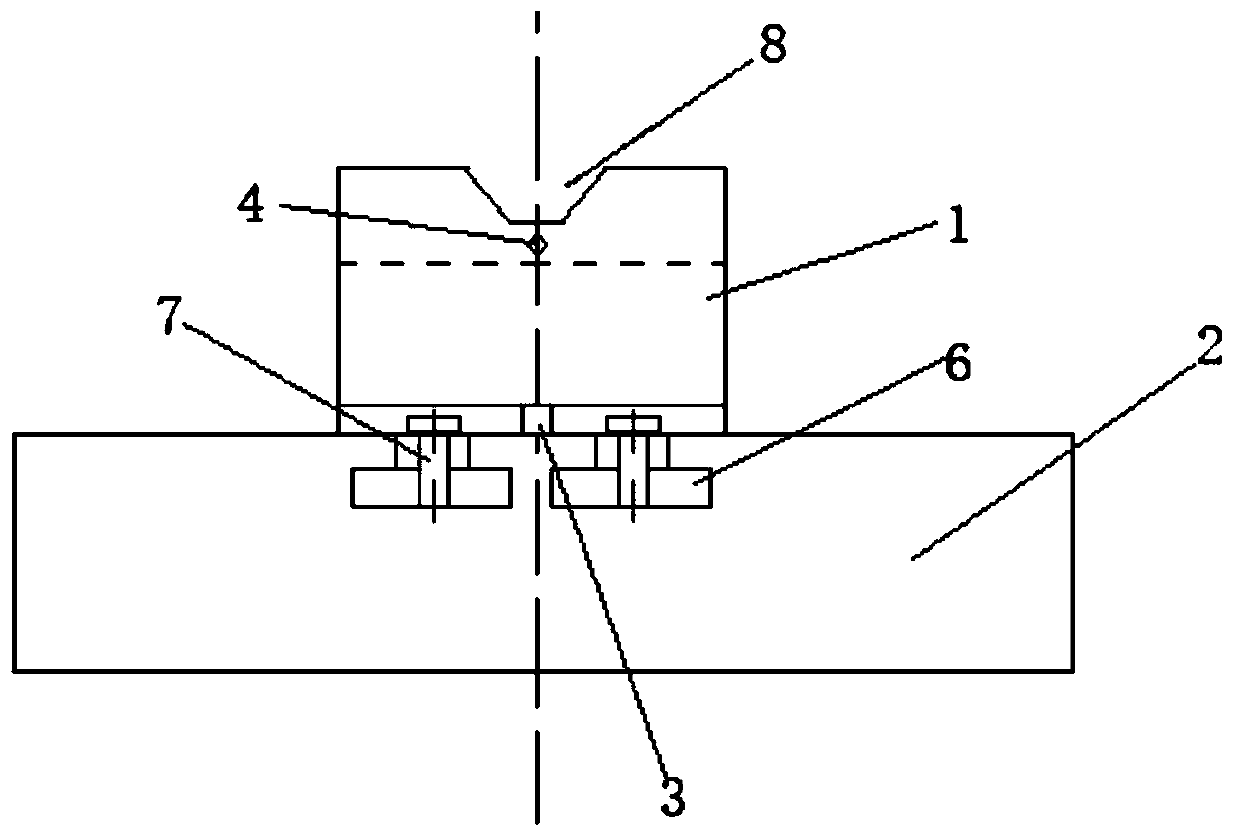

[0034] Such as Figure 1 to Figure 3As shown, a ball roundness and diameter detection device for a stylus of a coordinate measuring machine includes a measuring ball clamping seat 1, the lower end of the measuring ball clamping seat 1 is fixedly connected with the cylindricity measuring instrument workbench 2, and the measuring ball clamping seat 1. The middle part of the upper end is provided with a first measuring club hole 3, and the upper end of the measuring ball clamping seat 1 is located on both sides of the first measuring club hole 3. A second measuring club hole 4 and a third measuring club hole 5 are respectively provided. The axes of the second measuring club hole 4 and the third measuring club hole 5 are symmetrical about the axis of the first measuring club hole 3, and the second measuring club hole 4, the third measuring club hole 5 and the first measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com