Manual static headspace sample injection device of injector and manual static headspace sample injection method of injector

A technology of static headspace and sampling device, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of subjective reading deviation, difficulty in ensuring accurate extraction, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

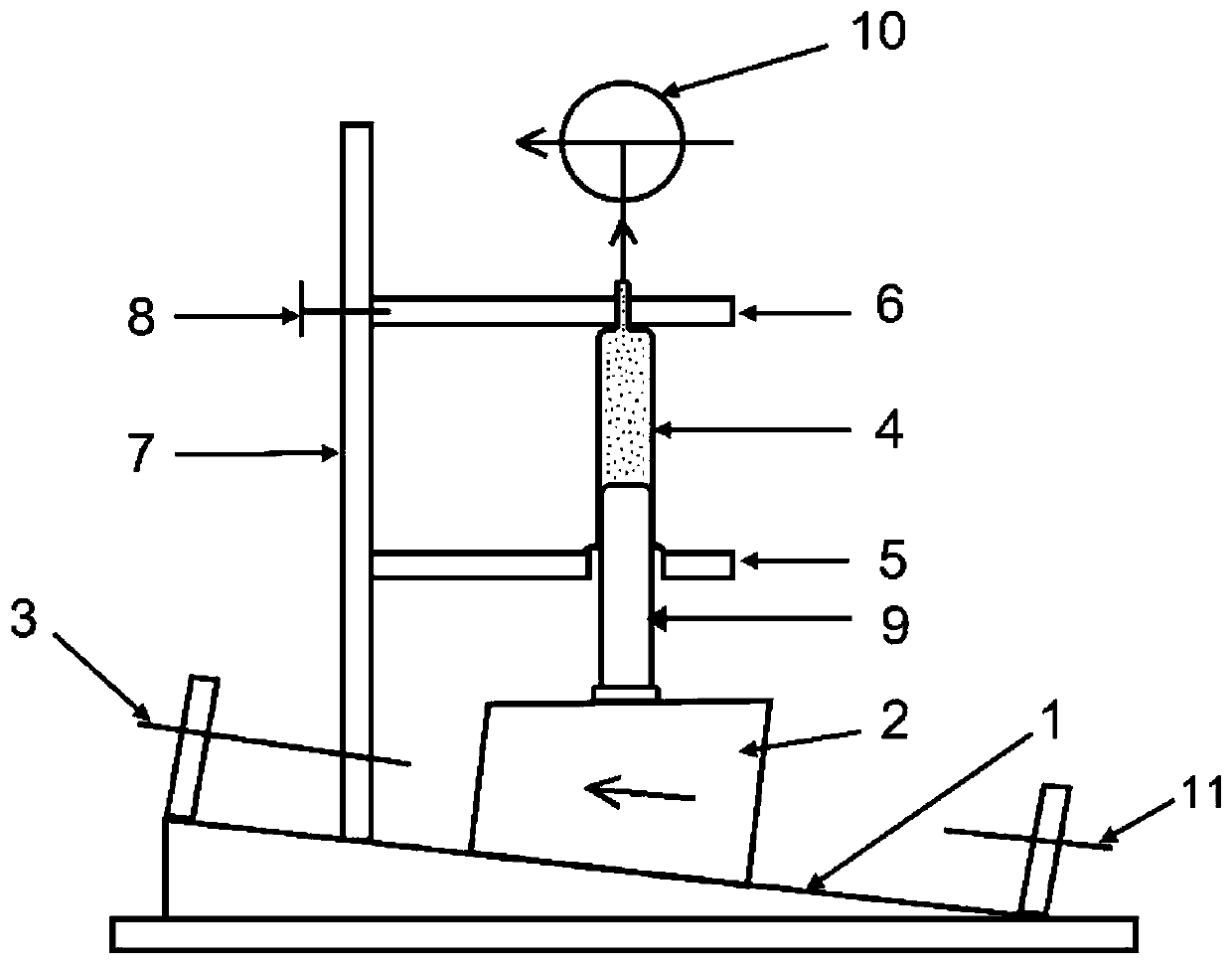

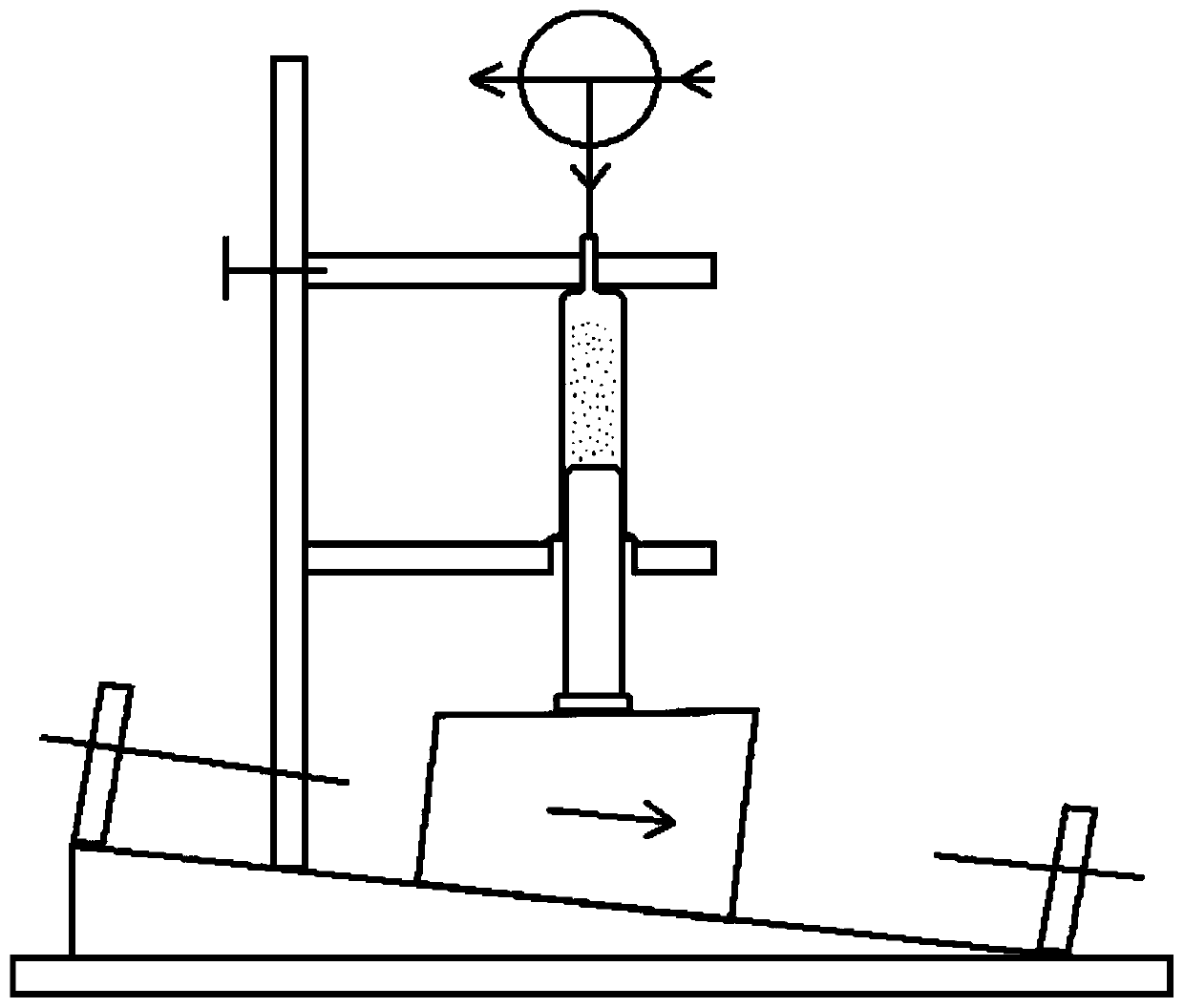

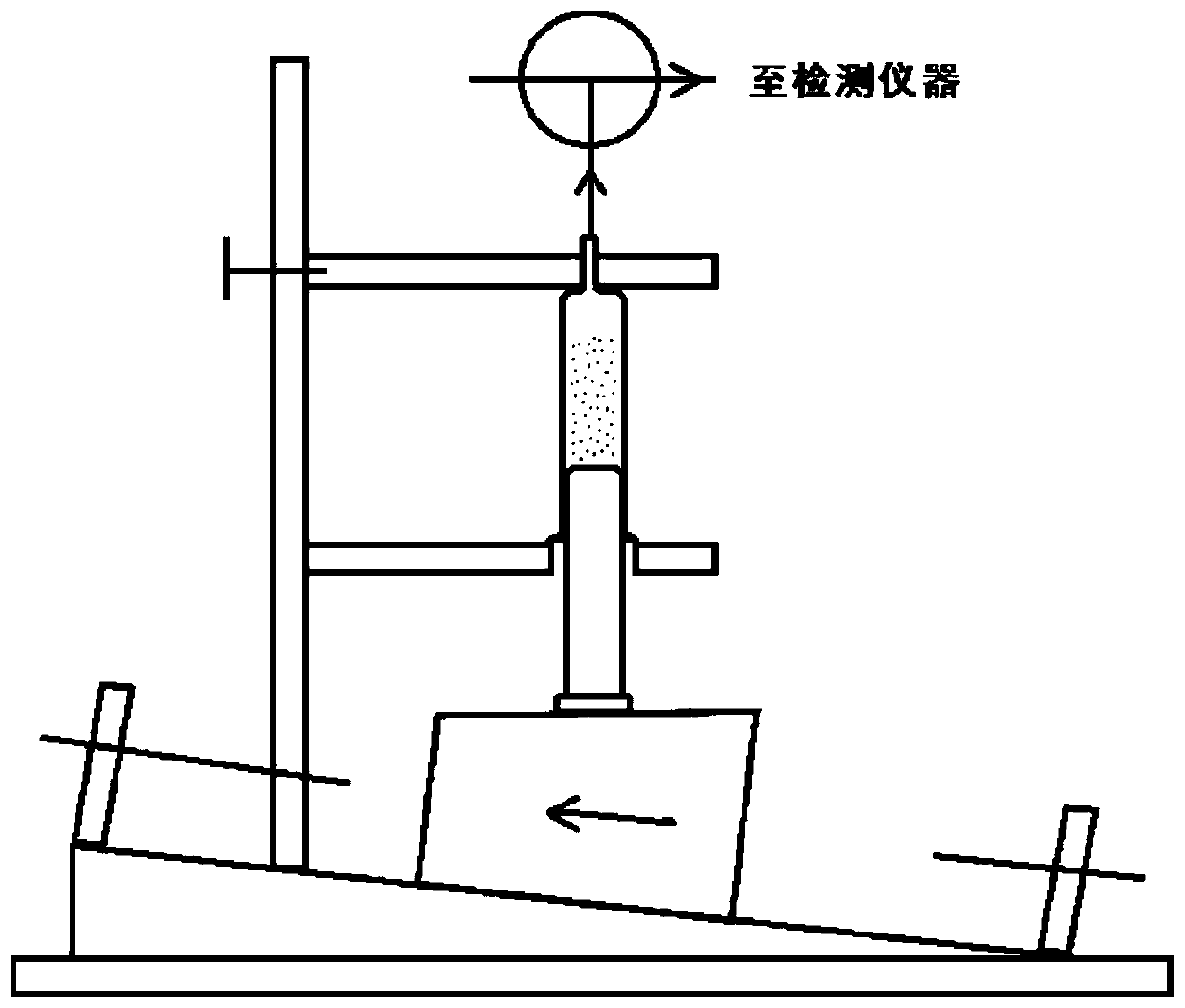

[0052] Such as figure 1 , figure 2 with image 3 As shown, a manual static headspace sampling device for a syringe, comprising: a slope body structure 1, a slope with a set inclination angle, and the inclination angle of the slope is 20°;

[0053] The slide block 2 is arranged on the slope through a slide rail, the slide rail is parallel to the inclination direction of the slope, and the slide rail is a dovetail groove. The dovetail groove can not only ensure the directional movement of the slider, but also effectively prevent the slider from slipping out of the dovetail groove;

[0054] The first support plate is arranged on the uppermost end of the slope, and an upper limit structure is arranged on it; the second support plate is arranged on the lowermost end of the slope, and a lower limit structure is arranged on it; the upper limit structure is the first screw rod 3, and the lower limit The bit structure is a second screw rod 11, the first screw rod 3 cooperates with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com