Remote alarm method for chemical device

A remote alarm and chemical equipment technology, applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve the problems of manufacturer loss, production capacity decline, shutdown and production shutdown, etc., to reduce the probability of equipment damage, ensure safety and order, and save energy. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

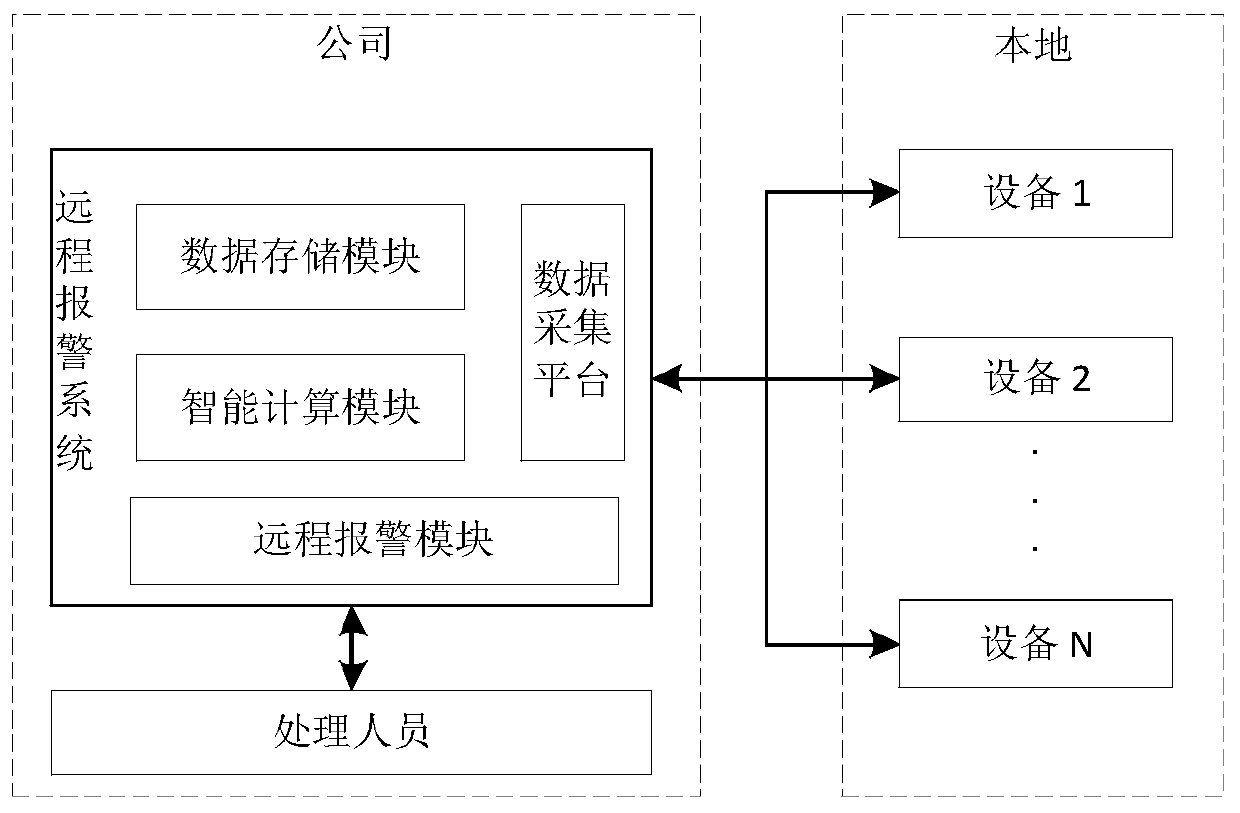

[0018] In the following, with reference to the accompanying drawings, taking the detection of whether a typical chemical equipment filling machine completes the action of closing the cover and giving an alarm as an example, the remote alarm method for chemical equipment of the present invention is further explained.

[0019] See figure 1 As shown, a remote alarm method for chemical equipment includes: a data acquisition platform, a data storage module, an intelligent computing module, a remote alarm system composed of a remote alarm module, a remote alarm system and related equipment 1, equipment 2, and a filling machine Device N communicates via Ethernet and uses TCP / IP protocol.

[0020] The filling machine production line is produced according to preset procedures, production parameters, time plans, etc.;

[0021] The remote alarm system is activated, and the filling machine performs the lid-closing process on the 200L steel drum;

[0022] The data acquisition module and data uplo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com