A kind of vertical suspension laying cable for ultra-deep mine and its production process

A technology for cable laying and production process, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of increasing potential risks, outer sheath damage, etc., and achieves the improvement of hoisting stability, weight reduction, and small outer diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

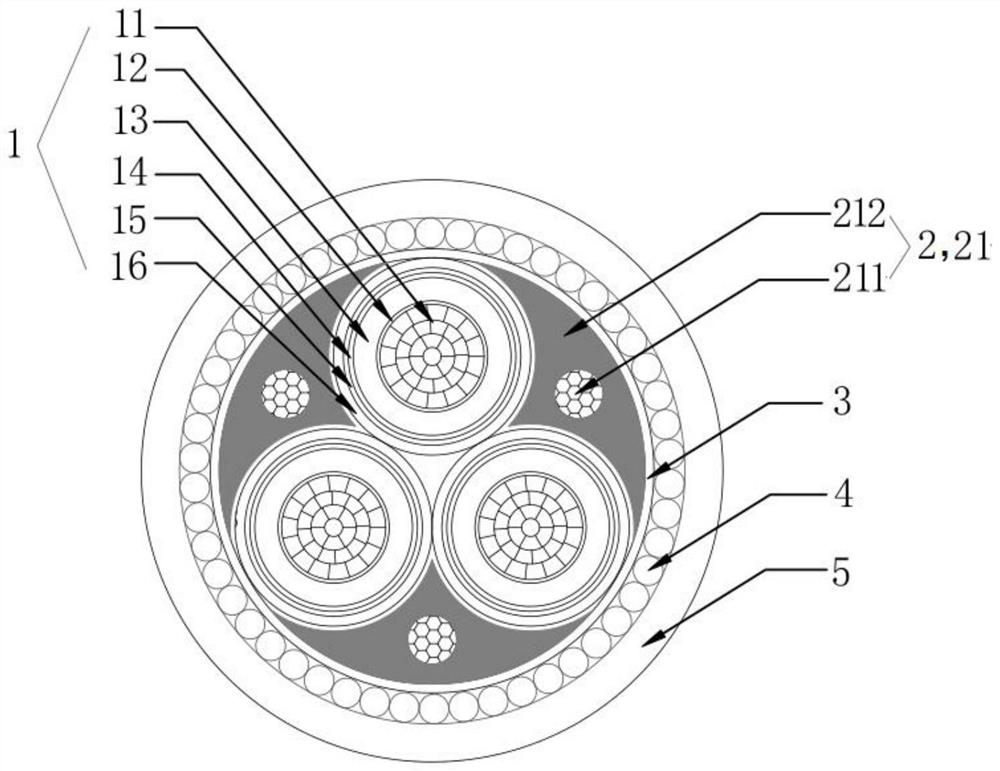

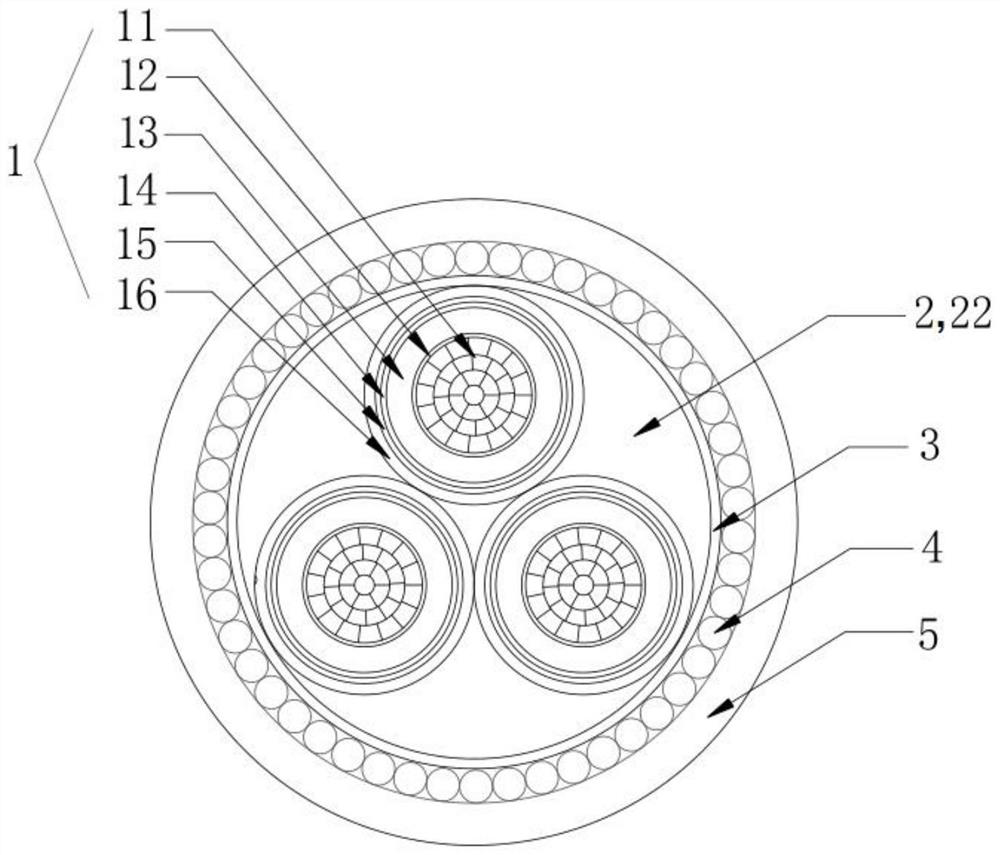

[0040] See Figure 1 to Figure 2 , the ultra-deep mine suspension laying cable of this embodiment includes a first section and a second section connected to each other, and the first section is vertically placed in the vertical shaft when laying; the first section and the second section include continuous The sheath and the cable core of different structures located in the sheath, the cable core includes a continuous insulated core 1 and a two-stage filling layer 2 arranged outside the insulated core 1; the two-stage filling layer 2 includes The bearing unit 21 arranged in the first section and the polypropylene filling 22 arranged in the second section; the sheath includes an inner sheath 3 and an armor layer 4 arranged outside the cable core in sequence from the inside to the outside and outer sheath5.

[0041] There are three insulated wire cores 1 and they are arranged tangentially in pairs. The insulated wire cores 1 are copper-shaped wires tightly pressed round conducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com