Method for determining laundry properties in a tumble dryer and tumble dryer suitable therefor

A washing and drying machine technology, which is applied to washing dryers/washing dryers, determines the characteristics of washings in washing dryers, and can solve problems such as the inability to distinguish the proportion of water and the proportion of washings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

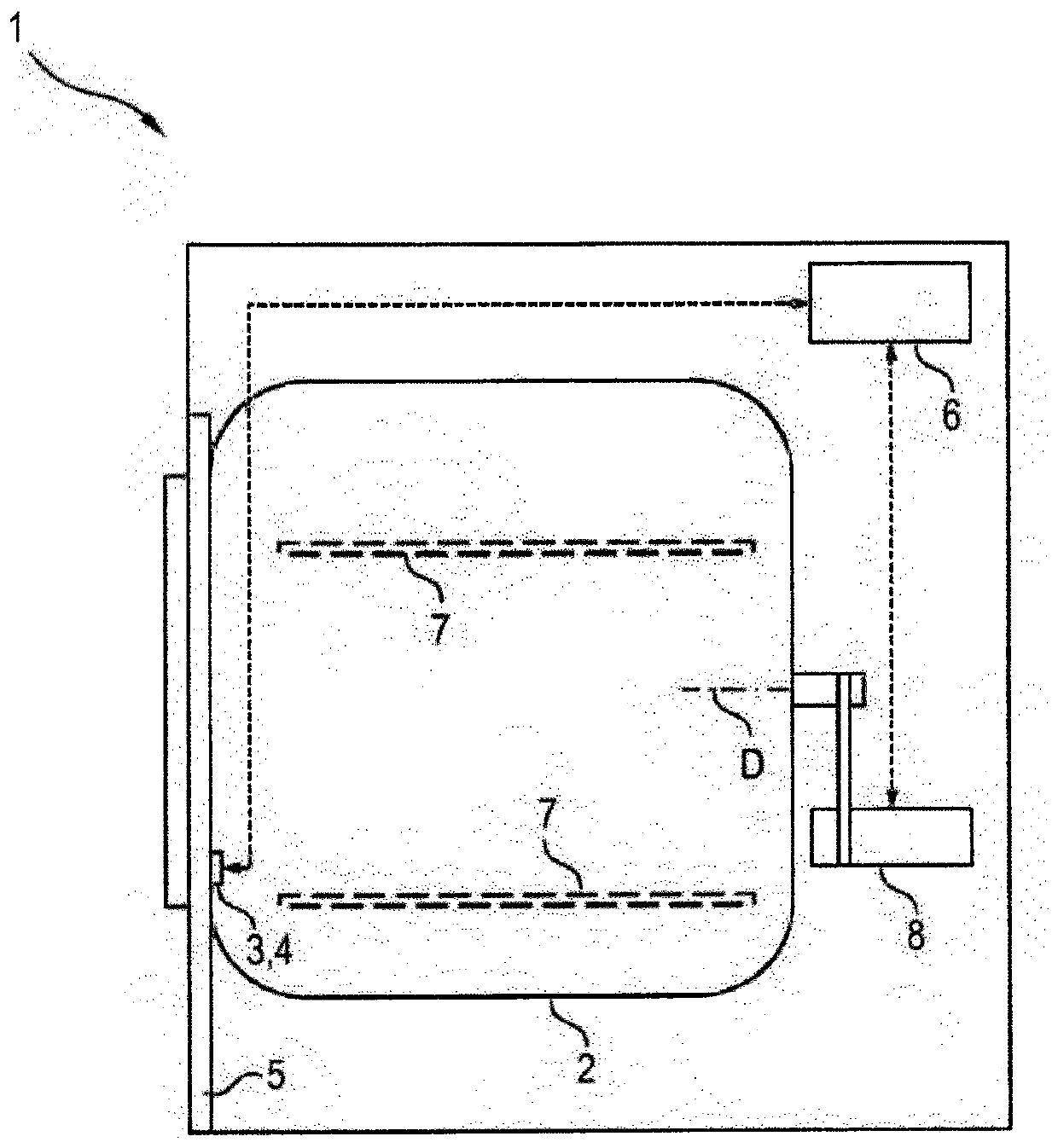

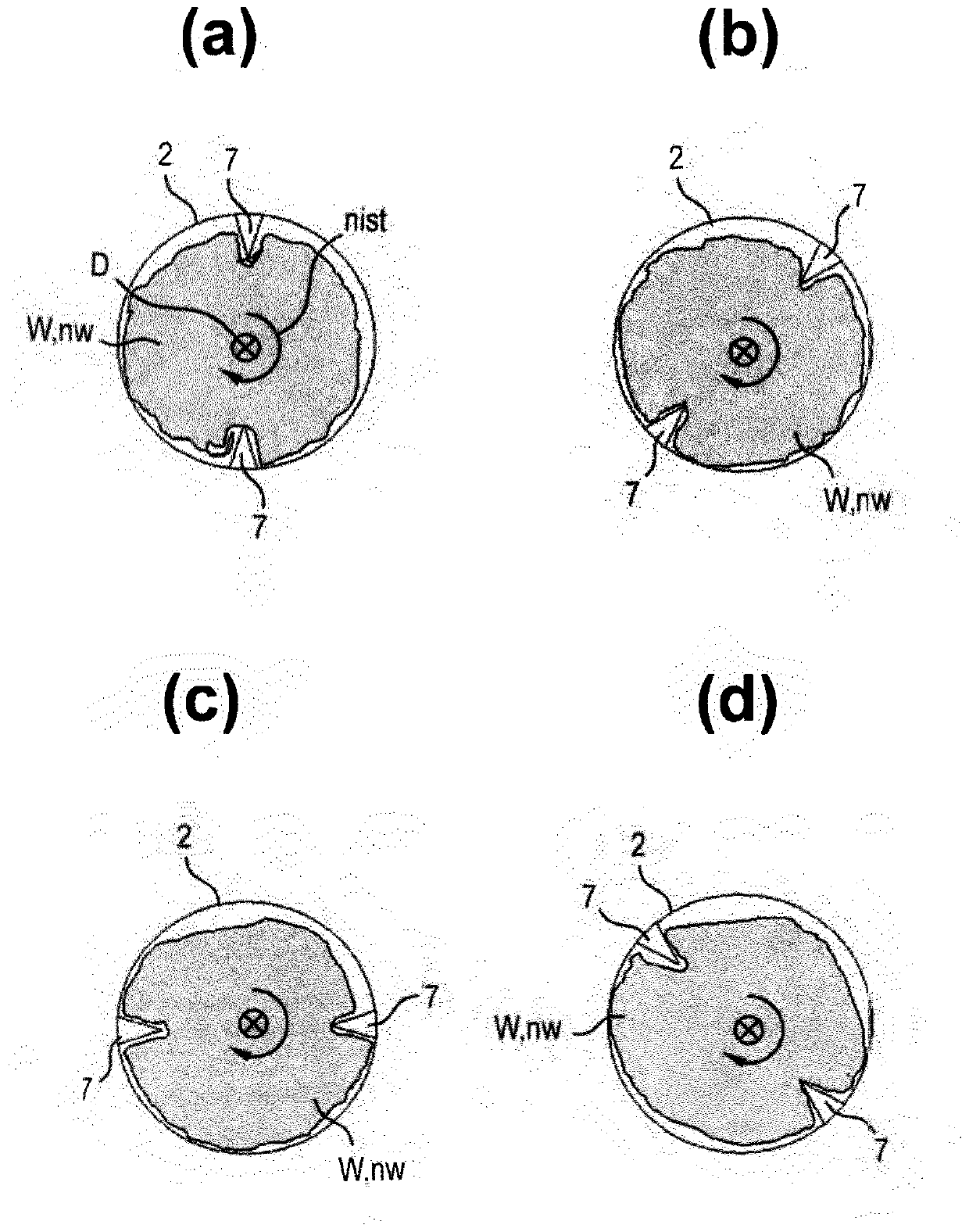

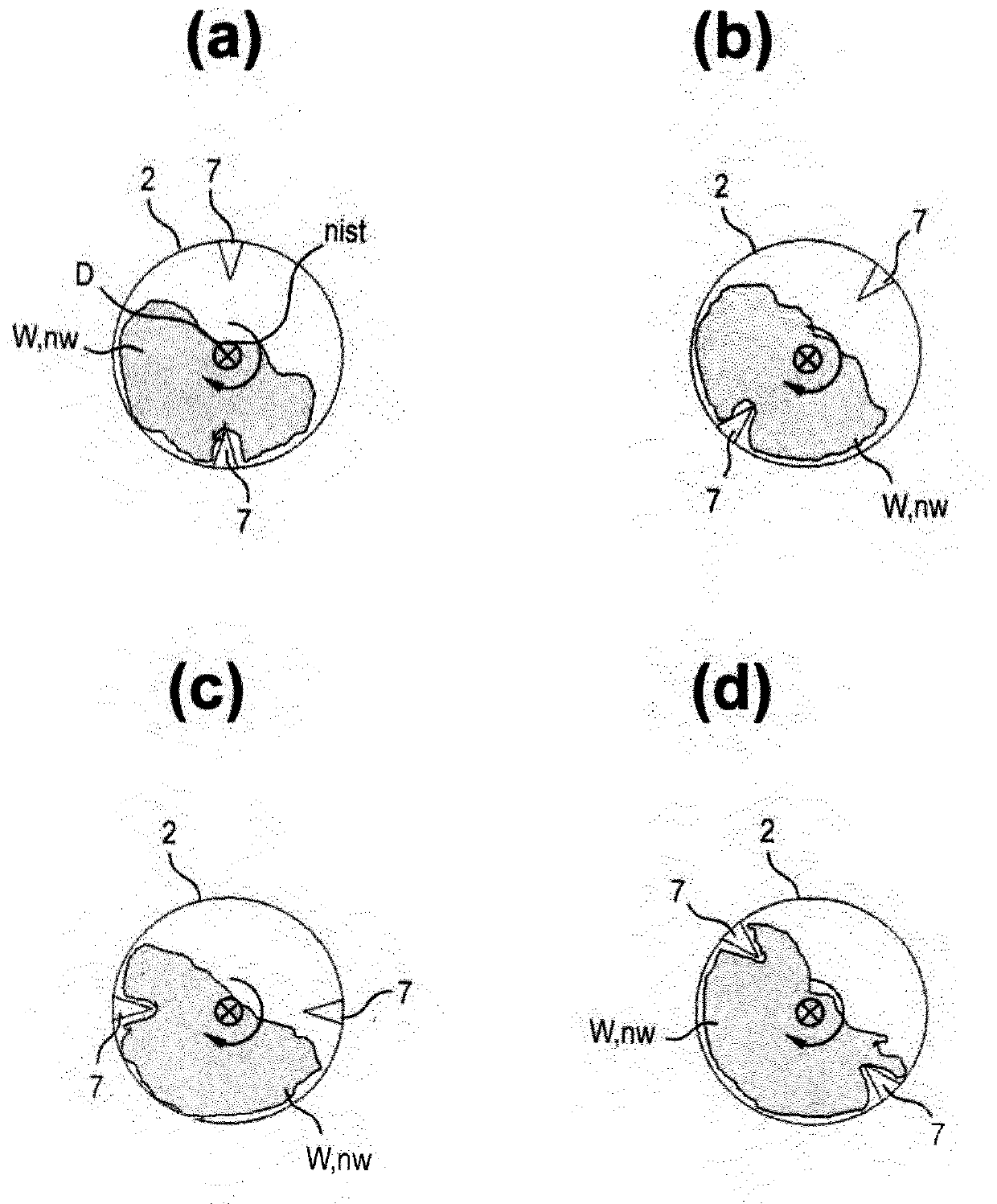

[0056] figure 1 A laundry dryer 1 with a horizontally rotatable laundry drum 2 in which the laundry W to be dried is located is shown in side view as a sectional view (see figure 2 (a)-(d) and image 3 (a)-(d)). The laundry dryer 1 also has an electrical resistance measuring device 3 for measuring the electrical resistance of the laundry W, said electrical resistance measuring device 3 having two measuring electrodes 4 arranged for contact with the laundry W, said measuring electrodes 4 being in front The bearing end cap 5 on the side is installed on the lower edge of the door opening.

[0057] The laundry dryer 1 is designed to apply a direct voltage or an alternating voltage to the measuring electrodes 4 . The resistance measuring device 3 is connected to a control unit 6 which can control the operation of the laundry dryer 1 either alone or in cooperation with an external server and / or an external control unit (eg a mobile control unit). In particular, the control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com