Lift pin holder

A technology of lifting pins and retainers, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

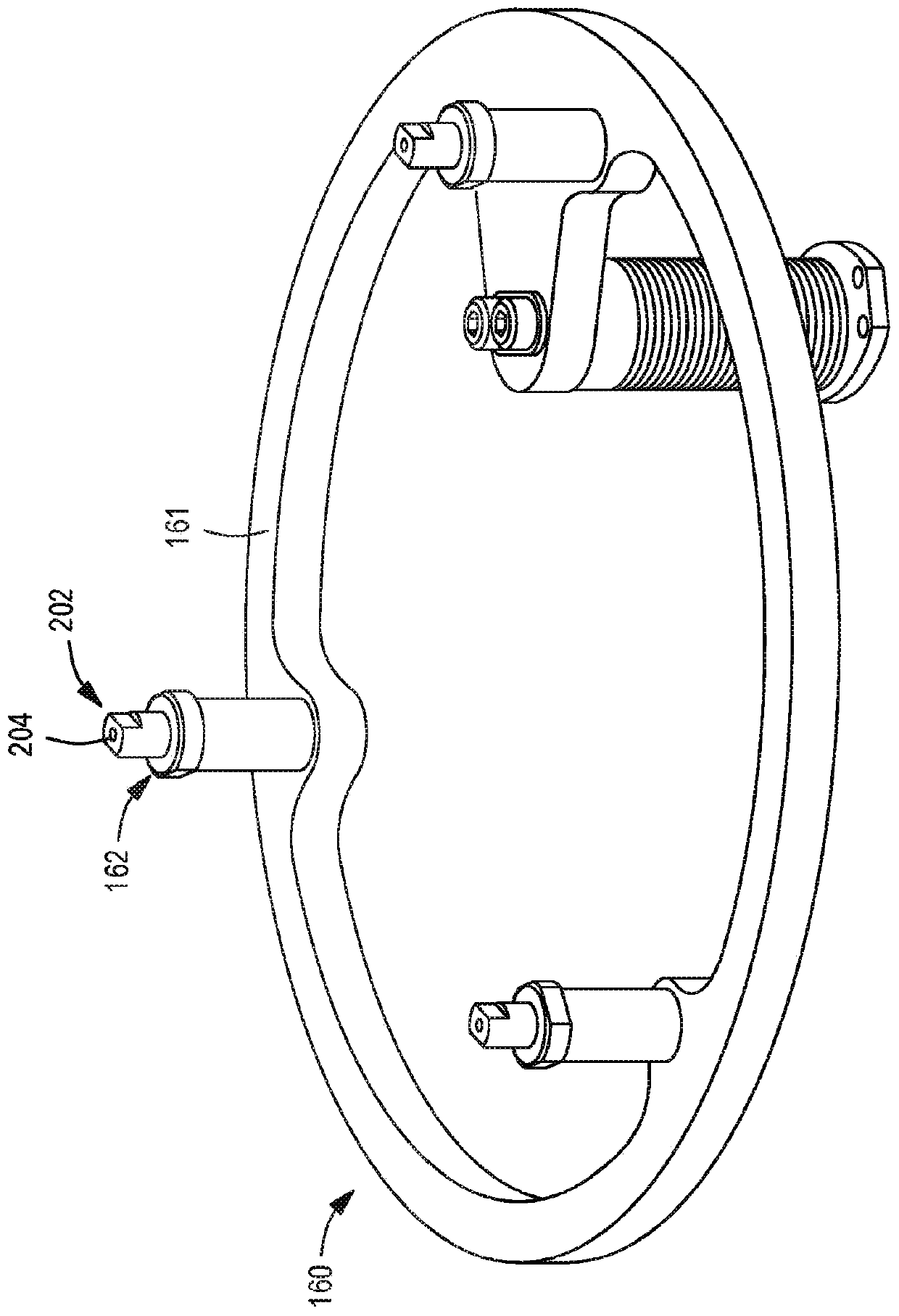

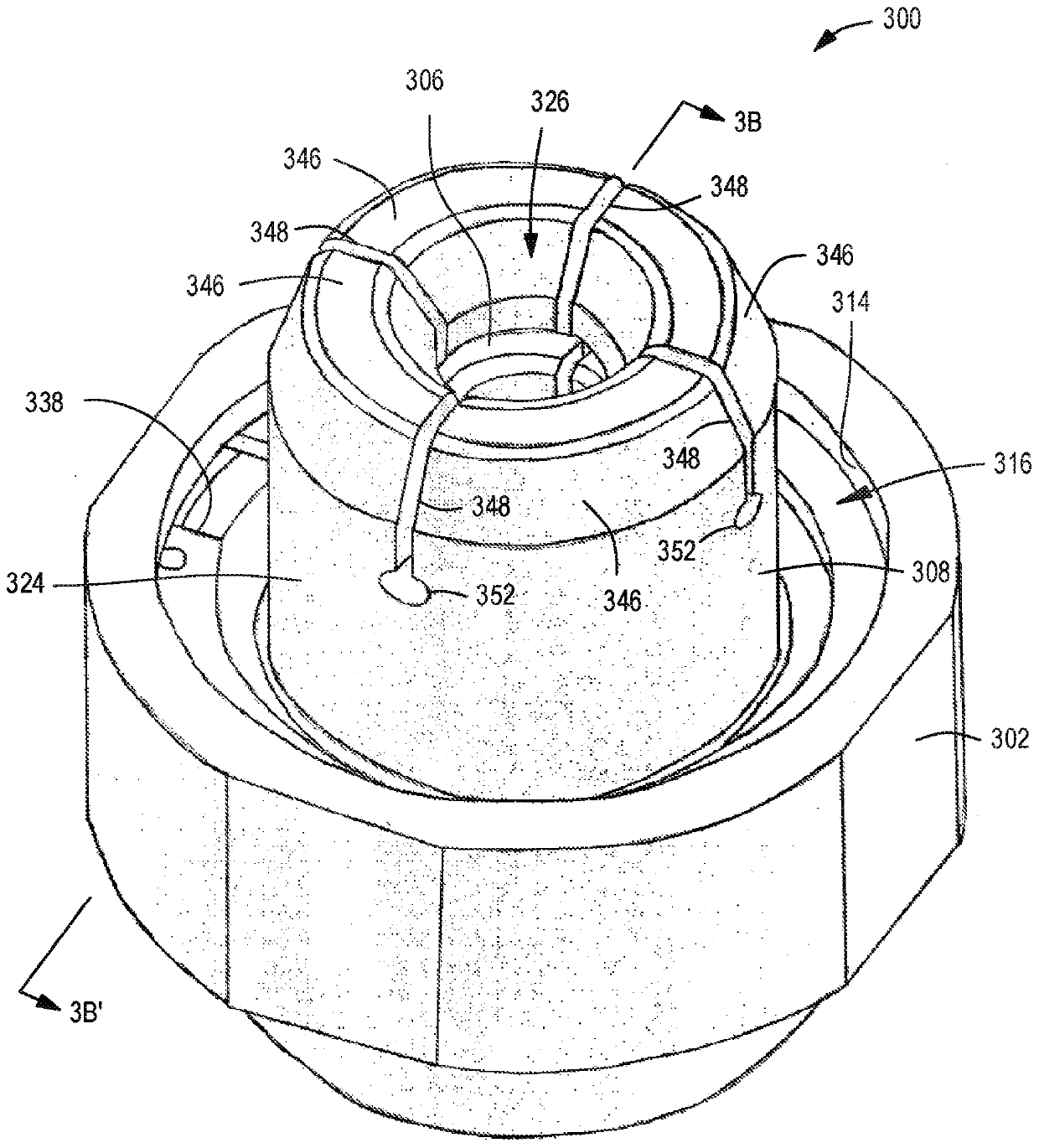

[0018] Embodiments of lift pin retainers and lift pin assemblies including the same are disclosed herein. The inventive lift pin retainer advantageously reduces or eliminates the problems of conventional lift pin retainers that cause the lift pin retainer to become jammed due to debris falling into the lift pin retainer. The inventive liftpin retainer eliminates sharp edges that could come into contact with debris falling into the liftpin retainer, thus significantly reducing the risk of elements of the liftpin retainer becoming caught by debris. The inventive lift pin retainer further improves lift pin stability by providing additional support to secure the lift pin within the lift pin retainer.

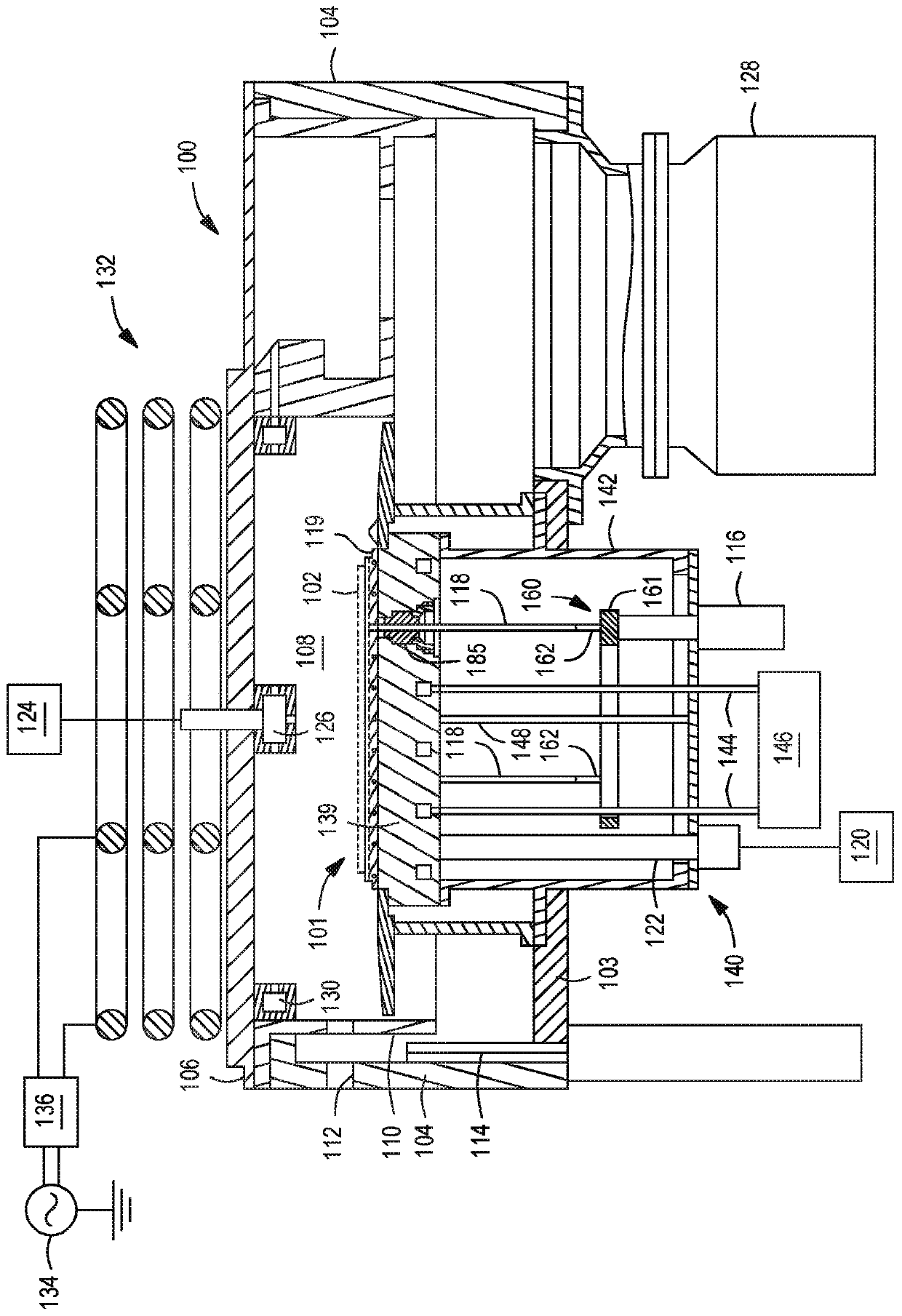

[0019] figure 1 A schematic cross-sectional view is depicted of an illustrative substrate processing chamber 100 in which a liftpin holder and liftpin assembly according to some embodiments of the present disclosure may be used. Suitable reactors that may be adapted for use with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap