Forming die for upper shell of automobile battery box

A technology for automotive batteries and forming molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the normal operation of batteries, increasing production costs, and low material utilization, so as to reduce welding and air tightness testing, etc. Process, save production cost, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

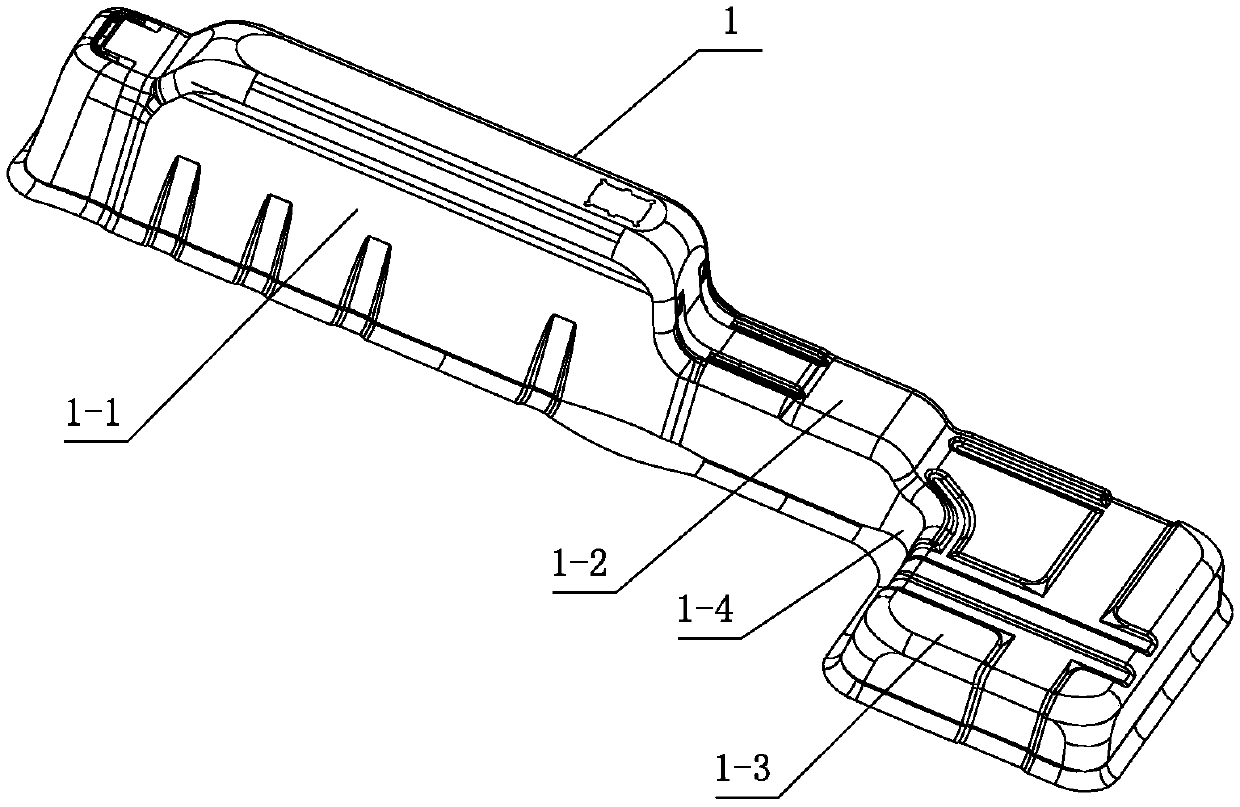

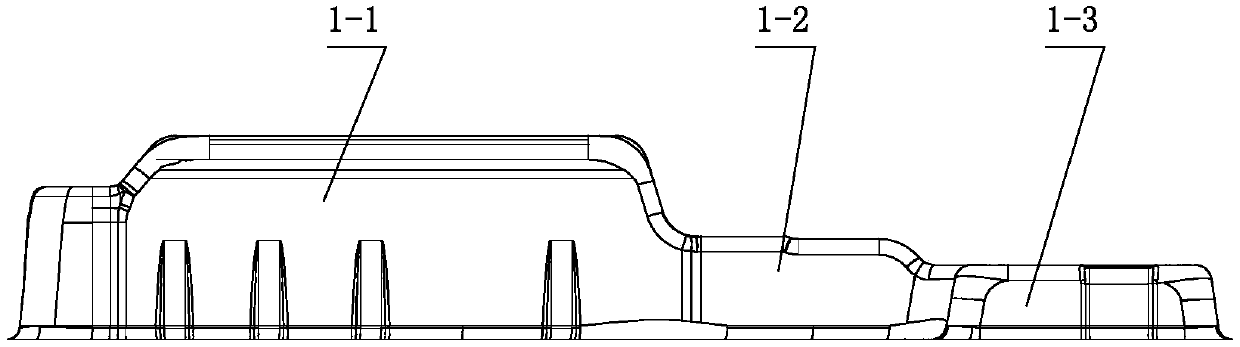

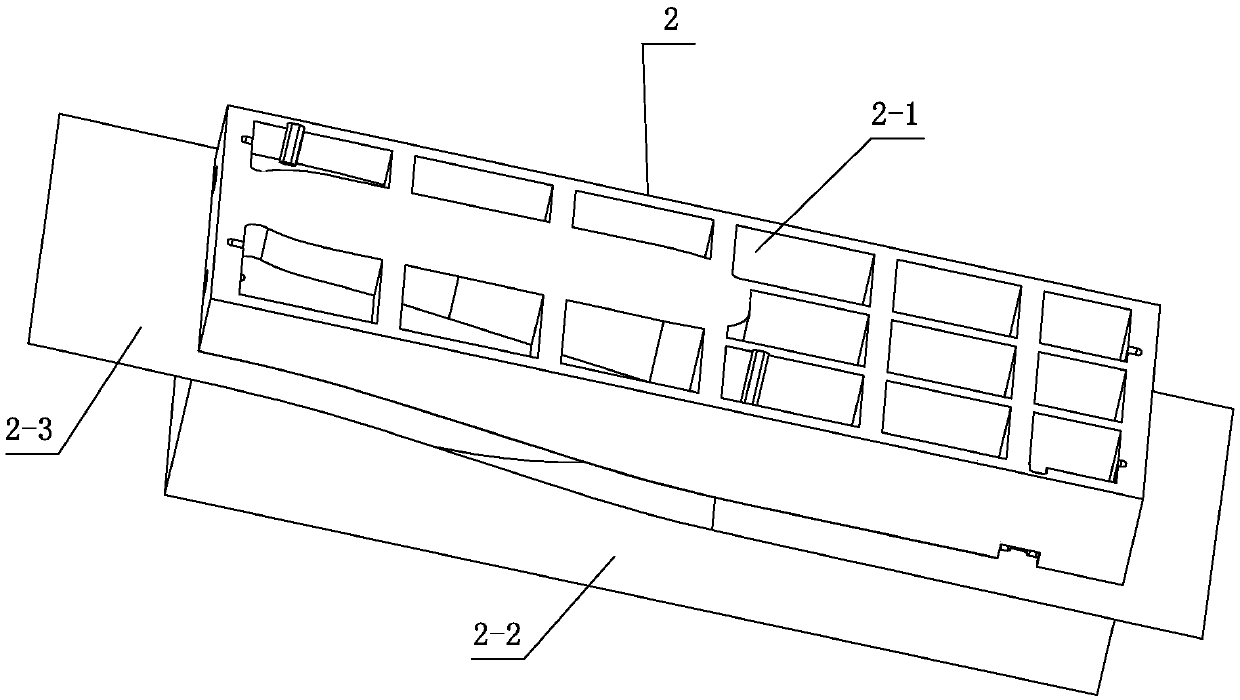

[0034] combine Figure 1 to Figure 12It can be seen from the structural schematic diagram of the forming mold of the upper casing of the automobile battery box of the present invention that it includes an upper mold assembly and a lower mold assembly, and a first drawing is arranged in sequence between the upper mold assembly and the lower mold assembly. Die assembly 2, second drawing die assembly 3 and shaping die assembly 4, wherein the first upper die 2-1 of the first drawing die assembly 2, the second upper die 3-1 of the second drawing die assembly 3 and The shaping upper die 4-1 of the shaping die assembly 4 is all connected on the upper die assembly, the first lower die 2-2 of the first drawing die assembly 2, the second lower die 3-2 of the second drawing die assembly 3 2 and the reshaping lower die 4-2 of the reshaping die a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com