Automatic manufacture equipment of rubber strips

A rubber strip and equipment technology, which is applied in the field of automatic rubber strip production equipment, can solve the problems that the rubber strip cannot be disconnected, the rubber strip cannot be sliced, and the production process is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

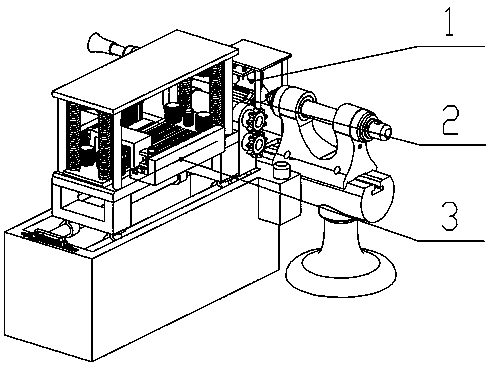

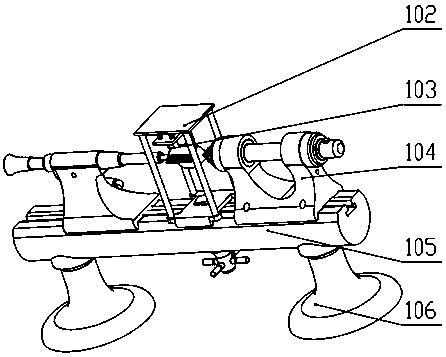

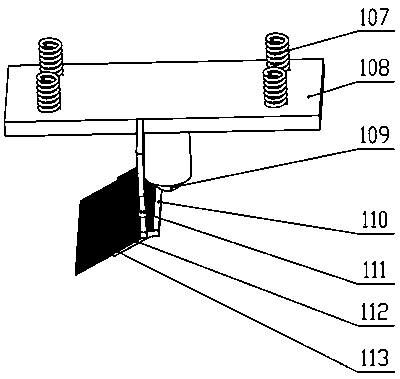

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown, a kind of equipment for automatically making rubber strips, comprising:

[0037] Slicing device 1; used for slicing rubber strips.

[0038] The flattening device 2 is arranged at the rear of the slicing device 1 and is used for flattening the rubber in pieces.

[0039] The shredding device 3 is arranged at the rear of the flattening device 2, and shreds the flattened rubber sheet.

[0040] The slicing device 1 includes a support frame 102, a slicing knife mechanism 103, a positioning device 104, a slide rail 105, and a foot 106. The foot 106 is fixedly installed on the lower end surface of the slide rail 105, and the support frame 102 is fixedly installed On the upper end surface of the slide rail 105 , positioning devices 104 are fixedly installed on both sides of the slide rail 105 , and the slicing knife mechanism 103 is fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com