Optical fiber releasing equipment of underground moving equipment of coal mine

A technology of mobile equipment and optical fiber, which is applied in the field of optical fiber release equipment for underground mobile equipment in coal mines. It can solve the problems of increasing the work intensity of staff, and achieve the effect of simple structure, convenient rotation, and prevention of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

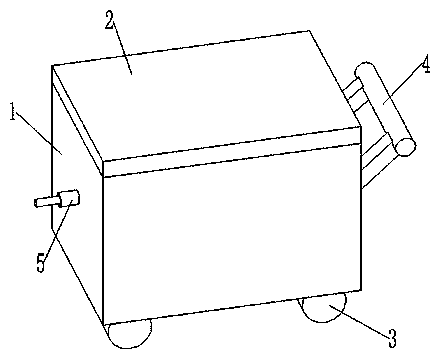

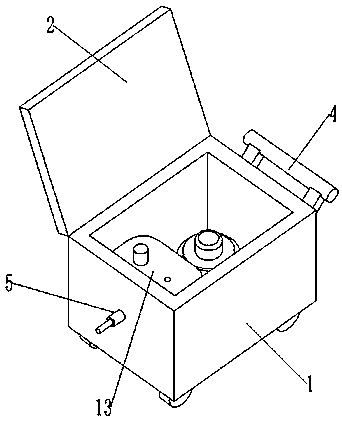

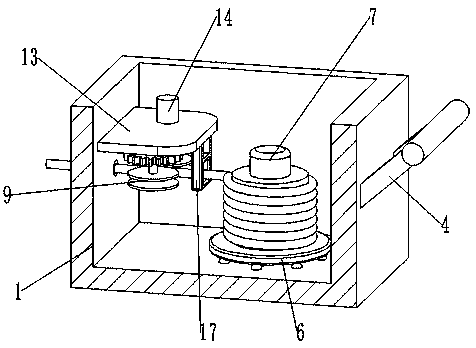

[0032] like Figure 1-Figure 5 The shown optical fiber release device for underground mobile equipment in coal mines includes a box body 1, a box cover 2, a turntable 6, a column 7, a first guide wheel 8, a second guide wheel 9, a lead tube 5 and a power mechanism.

[0033] like figure 1 and figure 2 As shown, the box body 1 defines an accommodating cavity with an open top, and the box cover 2 is rotatably connected with the box body 1, and the box cover 2 is suitable for covering the open end of the accommodating cavity.

[0034] Specifically, the box body 1 is roughly square in shape, and the box cover 2 is a square thin plate structure. By opening the box cover 2, the optical fiber line package can be placed in the box body 1, or the optical fiber line package can be replaced. The case cover 2, the case cover 2 can cover the open end of the accommodating chamber, so as to prevent dust and the like from entering the case body 1 when working underground.

[0035] like i...

Embodiment 2

[0046] Embodiment 2 is a further improvement to Embodiment 1.

[0047] like Figure 1-Figure 5 As shown, the box body 1 defines an accommodating cavity with an open top, the box cover 2 is rotatably connected with the box body 1, the box cover 2 is suitable for covering the open end of the accommodating cavity, the bottom of the box body 1 is provided with a roller 3, and the bottom of the box body 1 One side is provided with a push handle 4; the turntable 6 is located in the accommodation cavity, the turntable 6 is connected to the box body 1 in rotation, the turntable 6 is provided with a vertical column 7, and the turntable 6 is placed with an optical fiber line package, and the optical fiber line package is arranged on the On the column 7; the first guide wheel 8 and the second guide wheel 9 are all installed on the inner side wall of the accommodating chamber and connected with the box 1 in rotation, the first guide wheel 8 and the second guide wheel 9 are arranged opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com