A synchronous interlocking oil cylinder capable of cross control

An oil cylinder and cylinder barrel technology, which is applied in the field of synchronous interlocking oil cylinders, can solve problems such as safety accidents, complicated equipment installation, and hydraulic oil circuit bursting, so as to prevent safety accidents or equipment damage, simplify equipment installation and adjustment, and prevent safety accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

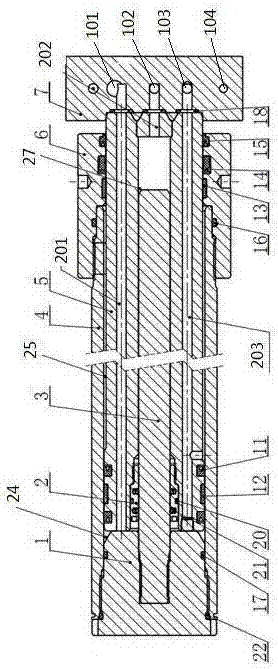

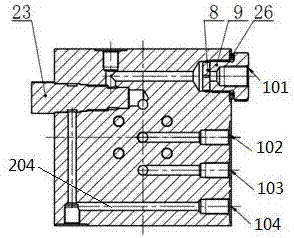

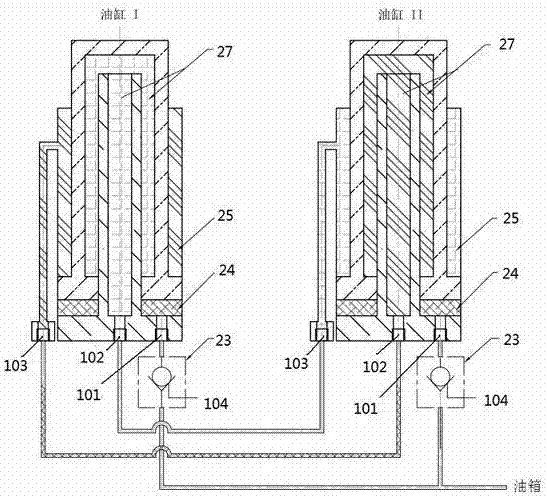

[0012] Embodiment: a synchronous interlocking oil cylinder that can be cross-controlled (see figure 1 , figure 2 ), which includes a cylinder 4, the rear end of the cylinder 4 is connected to the back cover 1, the fourth O-ring 17 and the fifth O-ring 22 are installed between the cylinder 4 and the back cover 1, and the inside of the cylinder 4 is provided with Piston rod 5, front end of cylinder barrel 4 and piston rod 5 are connected with front cover 6, guide ring 13, shaft seal ring 14, dustproof ring 15 are installed between front cover 6 and piston rod 5, front cover 6 and cylinder The first O-ring 16 is installed between the cylinders 4; the hole sealing ring 11 and the support ring 12 are installed between the piston rod 5 and the cylinder 4, and the front end of the piston rod 5 is connected to the valve block 7 by bolts, and the joint is provided with The second O-ring 18; the first oil port 101, the second oil port 102, the third oil port 103, and the fourth oil po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com