Polyethyleneimine diaphragm for preparing hydrogen for fuel cell, and preparation method thereof

A polyethyleneimine, fuel cell technology, applied in the direction of organic diaphragm, electrolysis process, asbestos diaphragm, etc., can solve the problems of affecting the ion conduction and internal impedance of the film, adverse effect on service life, poor modification effect, etc. Good hydrogen effect, stable performance, improved selectivity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

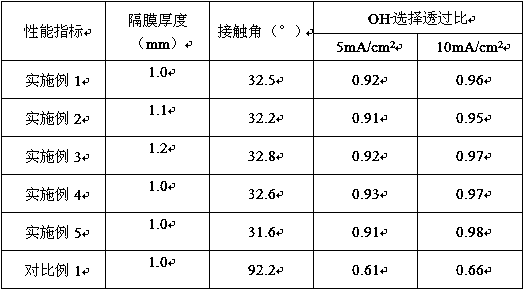

Examples

Embodiment 1

[0031] Add 7kg of γ-(2,3-glycidoxy)propyltrimethoxysilane and 33kg of polyethyleneimine into 49kg of deionized water, heat to 82°C and mix and stir at 112r / min for 52min, then add 11kg of polyvinyl alcohol Solution, adjust the pH value to 2, lower the temperature to room temperature, and continue to stir at a speed of 111r / min for 26min to obtain a sol; then add 3kgN,N-dimethylcyclohexylamine to the sol to convert the sol into a gel , then evenly coat the gel on the surface of an asbestos diaphragm with a thickness of 0.5 mm, and dry it for 3 hours in a mixed atmosphere of carbon dioxide and hydrogen chloride to further crosslink the gel and form a thin film on the surface of the base material; 26 kg of methyl bromide is maintained in 37 kg of methanol solution, after the reaction is complete, it is washed with 37 kg of deionized water and dried to prepare a silica-modified polyethyleneimine diaphragm.

[0032] testing method:

[0033] (1) Contact angle (hydrophilicity): Cut ...

Embodiment 2

[0037] Add 5kg of γ-(2,3-glycidoxy)propyltrimethoxysilane and 30kg of polyethyleneimine into 57kg of deionized water, mix and stir for 60min at a speed of 100r / min in a heating channel at 70°C, and then add 8kg of polyvinyl alcohol solution, adjust the pH value to 3, lower the temperature to room temperature, and continue to stir at a speed of 100r / min for 30min to obtain a sol; then 3kg of bis(2-dimethylaminoethyl)ether is added to the sol to convert the sol into gel, and then evenly spread the gel on the surface of an asbestos diaphragm with a thickness of 0.5mm, and dry it in a mixed atmosphere of carbon dioxide and hydrogen chloride for 2 hours to further crosslink the gel and form a thin film on the surface of the base material; Maintain in 35kg of methanol solution containing 20kg of methyl bromide. After the reaction is complete, wash with 45kg of deionized water and dry to prepare a silica-modified polyethyleneimine diaphragm.

[0038] The test method is consistent wit...

Embodiment 3

[0040] Add 10kg of γ-(2,3-glycidoxypropoxy)propyltrimethoxysilane and 35kg of polyethyleneimine into 43kg of deionized water, mix and stir for 40min at a heating path of 90°C at a speed of 120r / min, and then add 12kg of polyvinyl alcohol solution, adjust the pH value to 2, lower the temperature to room temperature, and continue to stir at a speed of 120r / min for 20min to obtain a sol; then add 2.8kg of triethylenediamine to the sol to convert the sol into a gel, and then The gel is evenly coated on the surface of an asbestos diaphragm with a thickness of 0.5 mm, and dried in a mixed atmosphere of carbon dioxide and hydrogen chloride for 4 hours to further cross-link the gel and form a film on the surface; place it in 40 kg of methanol containing 30 kg of methyl bromide After curing in the solution, after the reaction is complete, wash with 30 kg of deionized water and dry to prepare a silica-modified polyethyleneimine diaphragm.

[0041] The test method is consistent with Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap