Double-layer fabric knitting technology for one-time weaving and forming with different internal and external functions

A fabric and process technology, applied in the field of double-layer fabric knitting technology, can solve the problems of sewing stitches, inability to form three-dimensionally at one time, and inaccurate size and position of splicing process, etc., to achieve low production cost, accurate size fit, and short process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

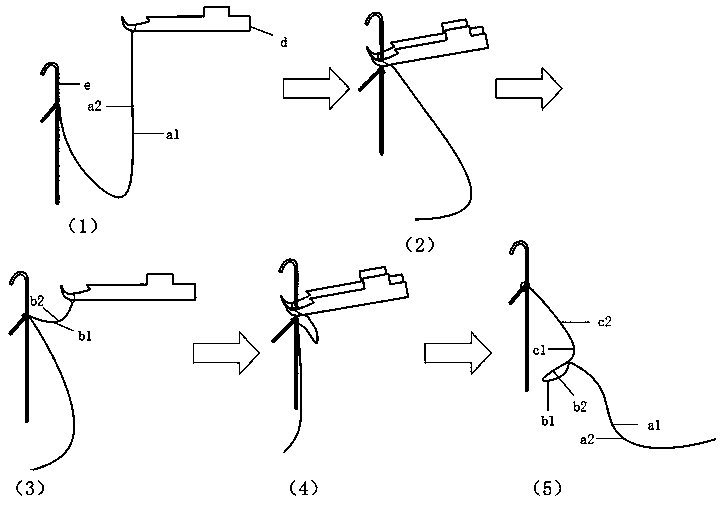

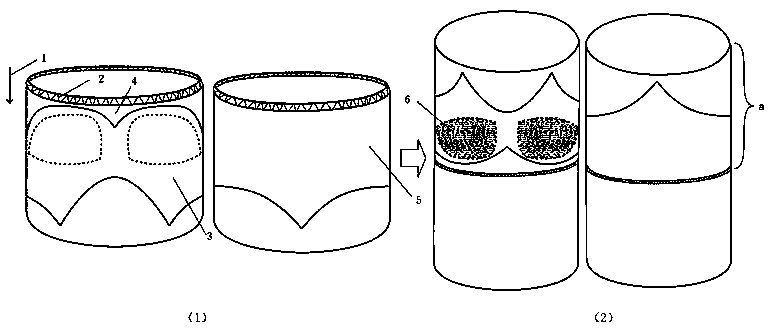

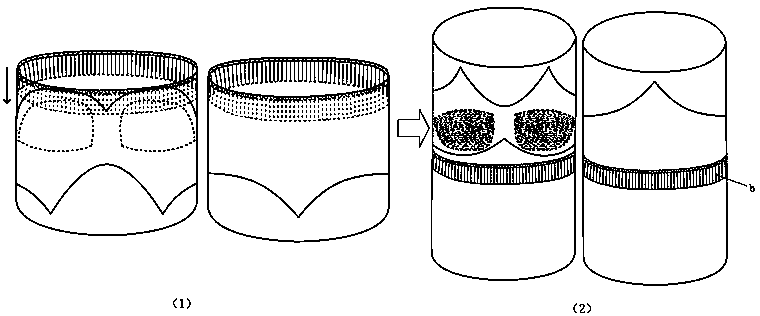

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples. The content mentioned in the examples is not a limitation of the present invention. The present invention is not limited to the weaving of seamless double-layer sports bras, and can also be used for any internal and external weaving with different functions. Forming a seamless double layer top or bottom knit.

[0023] Table 1 Distribution of ground yarn feeders

[0024] yarn feeder yarn yarn symbol 1, 5 roads tie line A 2, 6 roads Terry functional yarn B 3, 7 roads Body layer functional spandex covered yarn C 4, 8 roads Conventional spandex covered yarn on the outer layer D

[0025] Table 2 Allocation of veil yarn feeders

[0026] yarn feeder yarn yarn symbol 1, 3, 5, 7 roads Regular yarn for body layer E 2, 4, 6, 8 roads Functional yarn for the outer layer F

[0027] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com