Segmented elevated column grouting device

A segmented, column technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of low filling process efficiency, increased construction time, local stress concentration, etc., to avoid engineering quality problems, improve The effect of construction efficiency and project cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

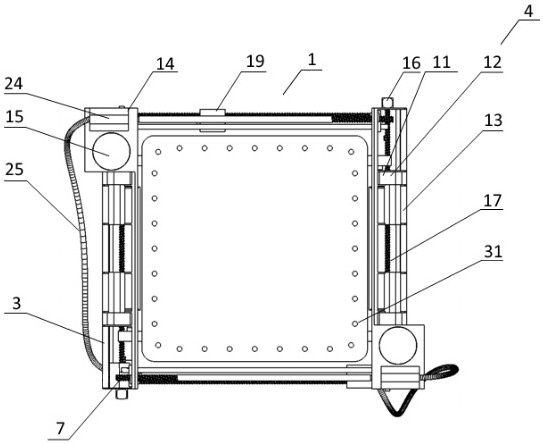

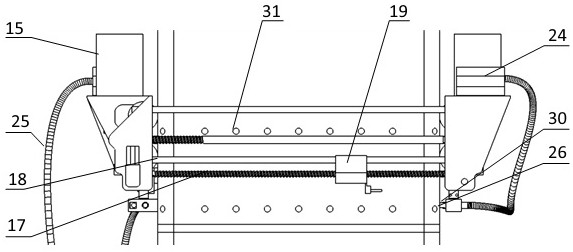

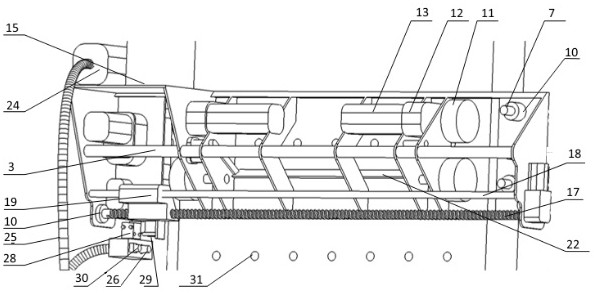

[0020] Such as Figures 1 to 4 As shown, this embodiment includes: two grouting mechanisms 2 mounted on the moving mechanism 1, wherein: the two grouting mechanisms 2 are arranged symmetrically and can work simultaneously.

[0021] Described moving mechanism 1 comprises: double-screw frame 3, vertically moving assembly 4 and horizontally moving assembly 5, wherein: the distance between double-screw frame 3 can be adjusted, and vertically moving assembly 4 and horizontally moving assembly 5 are all arranged on 3 on the twin screw rack.

[0022] The double-screw frame 3 is provided with a pillar assembly 6 to fix the relative position of the moving mechanism 1 and the pillar.

[0023] The column holding assembly 6 includes: a locking screw 7, a locking reducer 8, a locking servo motor 9, and a locking nut 10 connected in sequence, wherein: the joint action of the locking nut 10 and the locking screw 7 makes Twin-screw frame 3 adjusts spacing according to the width of column. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com