A method for drilling open holes in shale formations

A mud shale and stratum technology, applied in the field of drilling, can solve complex and changeable drilling bit sticking, well wall collapse accidents cannot be effectively resolved, etc., to achieve the effect of improving the success rate and avoiding drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1. Basic overview:

[0065] Well J10021_H, the design well depth is 4939.51m, the actual well depth is 4937m, the third well section is 215.9mm drill bit + 139.7mm reservoir casing. It was opened at 8:00 on April 2, 2019 and completed at 14:30 on September 2, 2019.

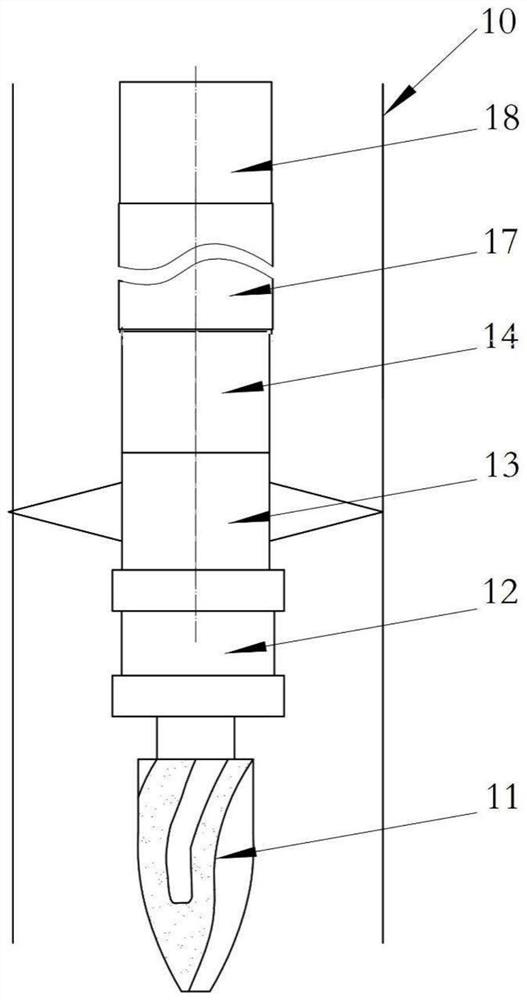

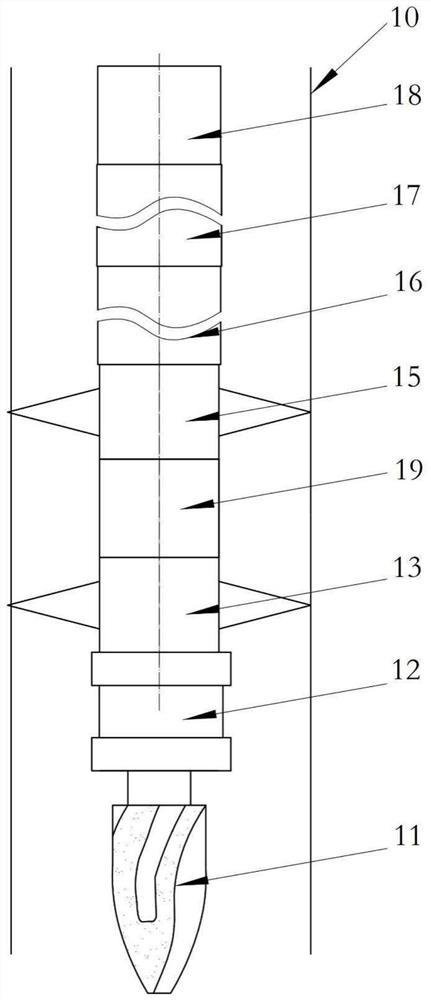

[0066] After the drilling was completed on August 5, 2019, the well was drilled in two trips. The first trip through the well adopts the roller cone single-supported drilling tool assembly, which includes successively connected roller cone bits, double female joints, 212mm centralizers, 2 strings of heavy drill pipes, 60 strings of drill pipes, and heavy drills 18 strings of rods and drill pipes were blocked when they were drilled through the well to 3840m. During the reaming process, the drill stuck twice. The second trip through the well adopts the roller-cone double-supported drilling tool assembly. The roller-cone double-supported drilling tool assembly includes successively connected roller cone bits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com