Canned reactor coolant pump locking cup local video inspection method

An inspection method and locking technology, used in pump control, non-variable-capacity pumps, measuring devices, etc., can solve the problems of complex inspection paths, narrow inspection spaces, affecting unit operation, etc., and achieve short inspection construction period and high inspection efficiency. , the effect of saving inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

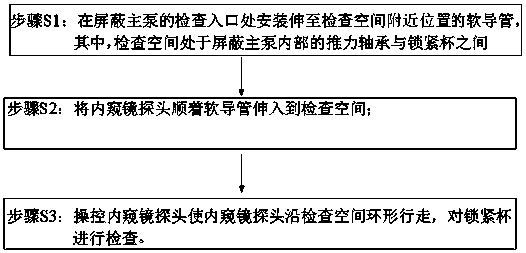

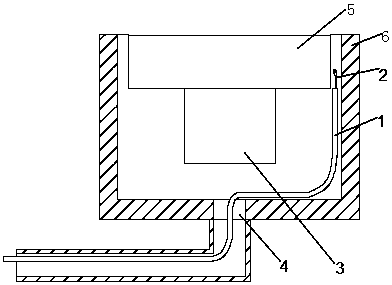

[0026] Embodiment 1: An in-situ video inspection method for shielding the locking cup of the main pump, as shown in the figure, includes the following steps:

[0027] Step S1: Install a flexible conduit 1 extending to a position near the inspection space at the inspection entrance of the shielded main pump, wherein the inspection space is between the thrust bearing and the lock cup inside the shielded main pump, and the inspection entrance is the shielded main pump. The water inlet at the lower end of the pump, the soft conduit 1 has certain rigidity and certain flexibility, and must be able to maintain its invariance after bending; It is an operation method that can be well operated on site and is suitable for the complex environment where the shielded main pump is located; the direction of the soft conduit 1 depends on the specific structure of the shielded main pump. Specifically, in this embodiment, the soft conduit 1 The path extended to the location near the inspection s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com