High-reliability large-span steel wire reinforced core bundled overhead line and processing process thereof

A technology of steel wire reinforcement core and processing technology, which is applied in the direction of power cables for overhead applications, manufacturing wire harnesses, conductors, etc., can solve the problems of inconvenient construction of wires, and achieve improved tensile capacity, high reliability, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

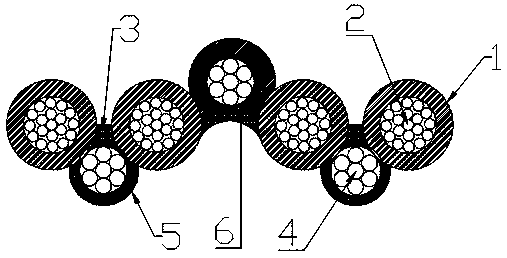

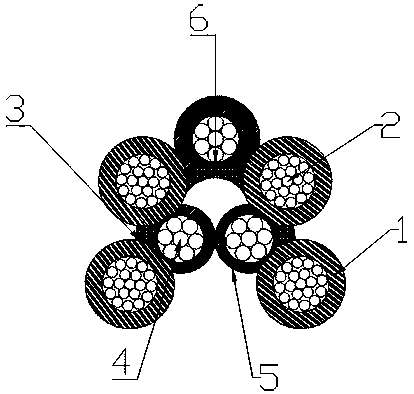

[0022] On the basis of the above embodiments, in this embodiment, a tungsten alloy steel wire is arranged at the center of the steel rope 4 , and the high tensile strength of the tungsten alloy is used to increase the overall tensile strength of the steel rope 4 .

Embodiment 3

[0024] On the basis of the above-mentioned embodiments, in this embodiment, the most central steel rope 4 is arranged above the insulating layer 1, and the rest are arranged below the insulating layer 1, so that the steel ropes formed in this way present a triangular shape with higher stability .

Embodiment 4

[0026] On the basis of the above embodiments, in this embodiment, the wires 2 of the row are bent into a tower shape at the connection between the central connecting rib 3 and the two sides of the insulating layer 1, which is convenient for construction selection.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap