3D printing-based percutaneous puncture needle structure for urology

A 3D printing and urology technology, applied in the field of medical devices, can solve problems such as being easily squeezed and bent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

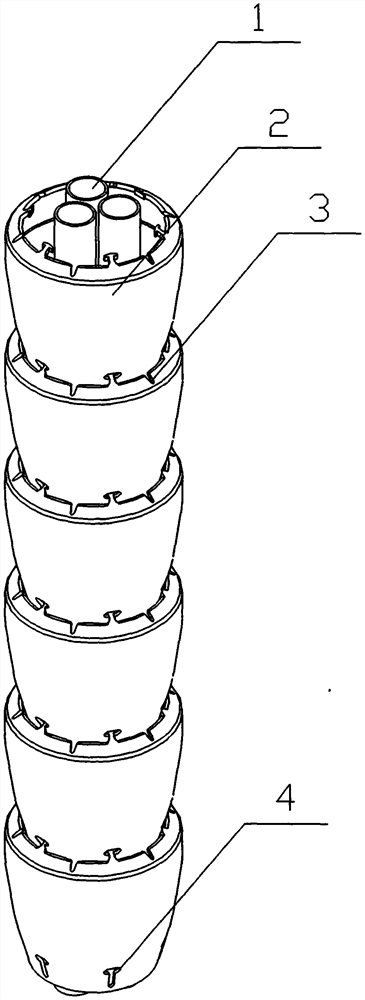

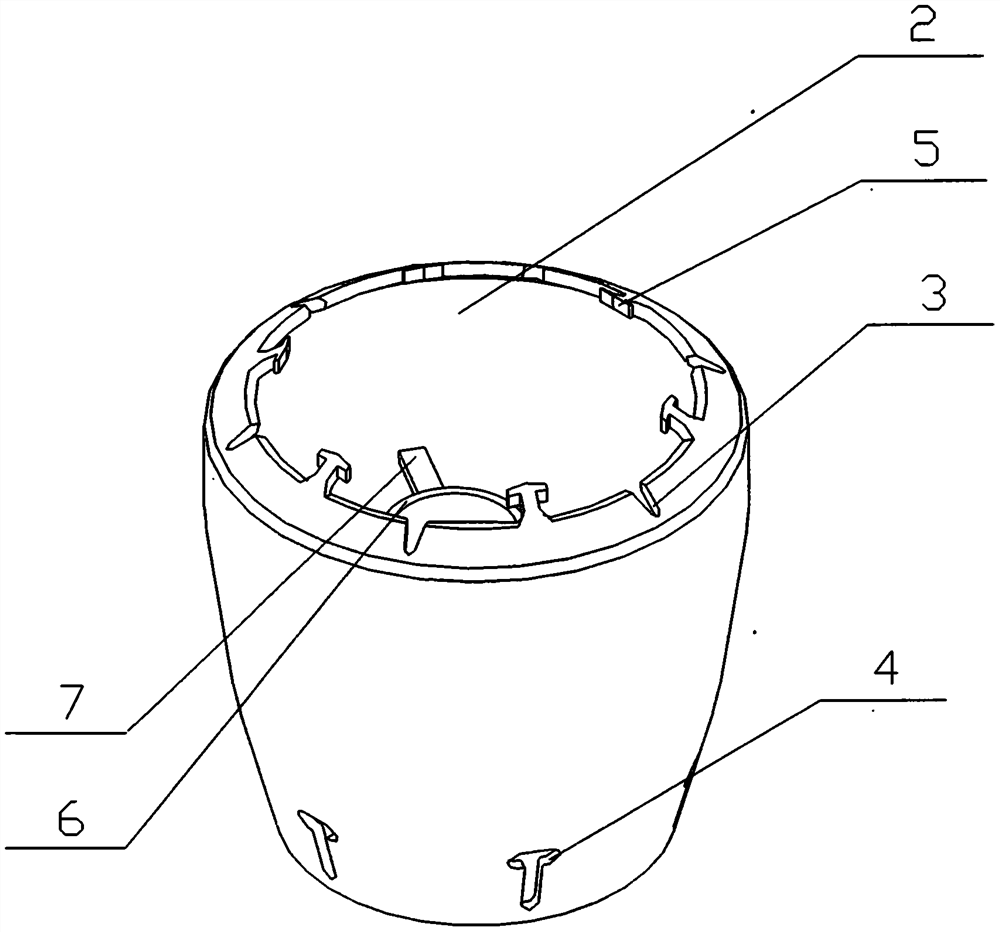

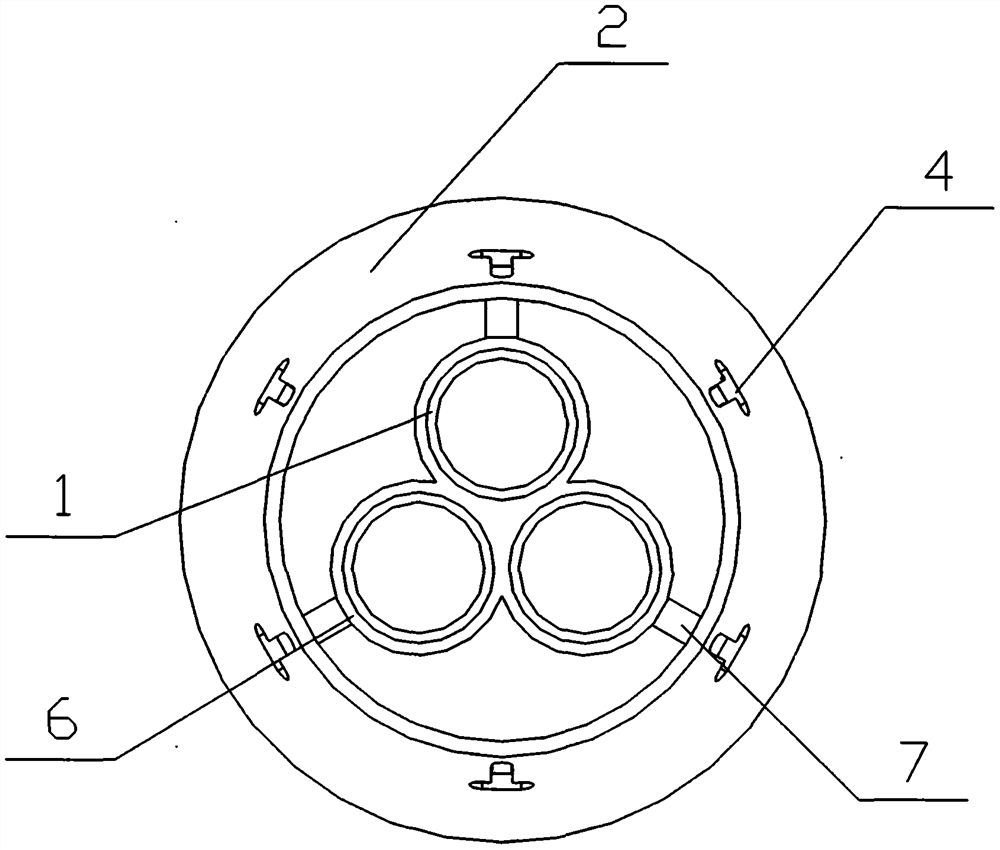

[0018] The 3D printing-based urological percutaneous puncture needle structure of the present invention is realized in the following way: the 3D printing-based urological percutaneous puncture needle structure of the present invention includes a plurality of 3D printed puncture needle segments 2 and soft air tubes 1 passing through the needle segments Composition, the puncture needle section 2 is a vacuum ring structure, and one end is retracted to form a circular table, and the other end is bent inward to form an inner flange, and a plurality of adjustment grooves 3 are opened on the inner flange, and the adjustment grooves 3 Divide the inner flange into a plurality of independent areas, the edge of the inner flange is provided with a plurality of clamping blocks 5, and the clamping blocks 5 are correspondingly placed in the middle of the independent area, and the clamping blocks 5 are T-shaped structures , a plurality of clamping grooves 4 are placed on the circular table sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com