Platform surface cleaning mechanism

A technology for cleaning mechanisms and countertops, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of short maintenance cycle, time-consuming and labor-intensive, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

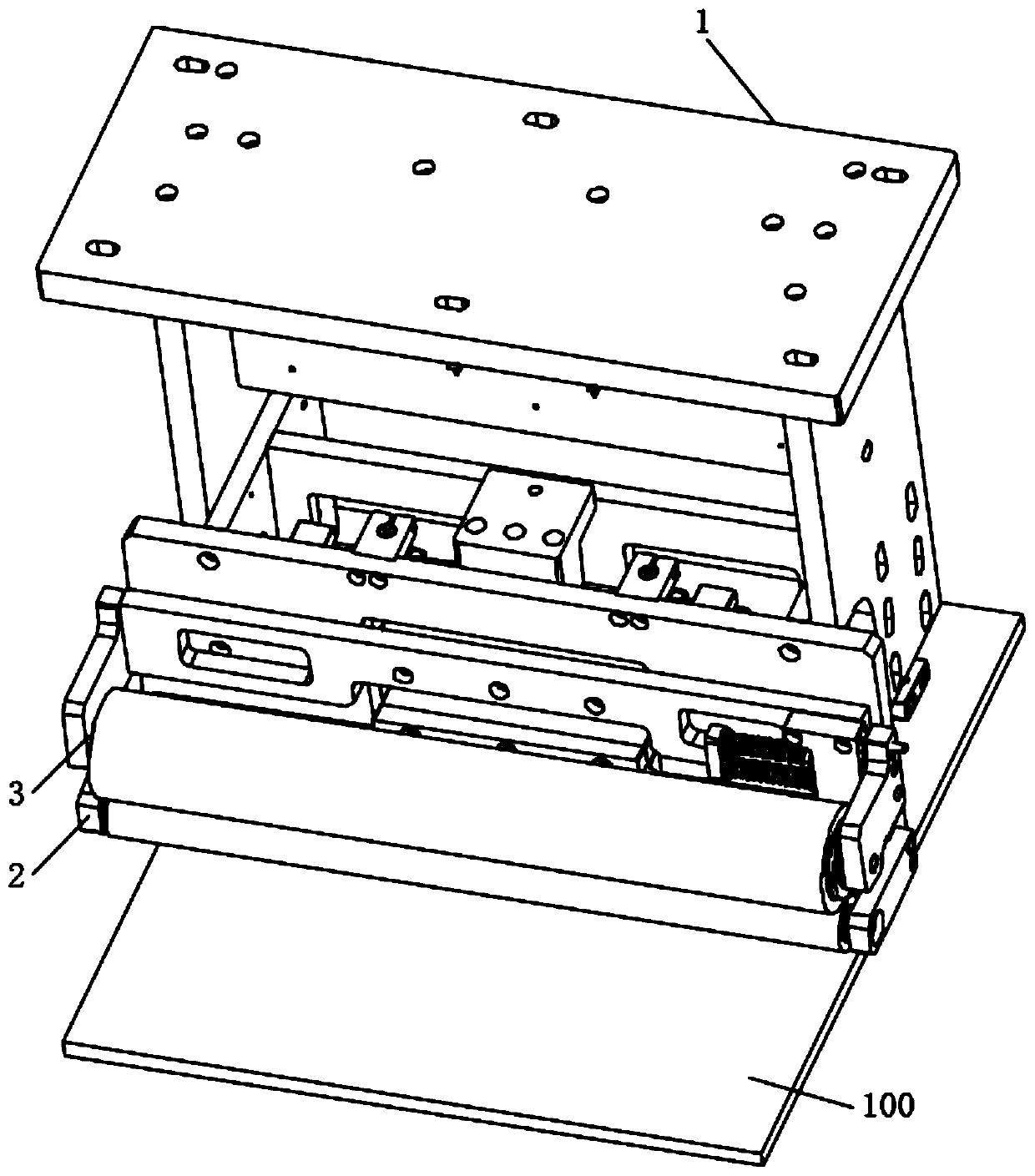

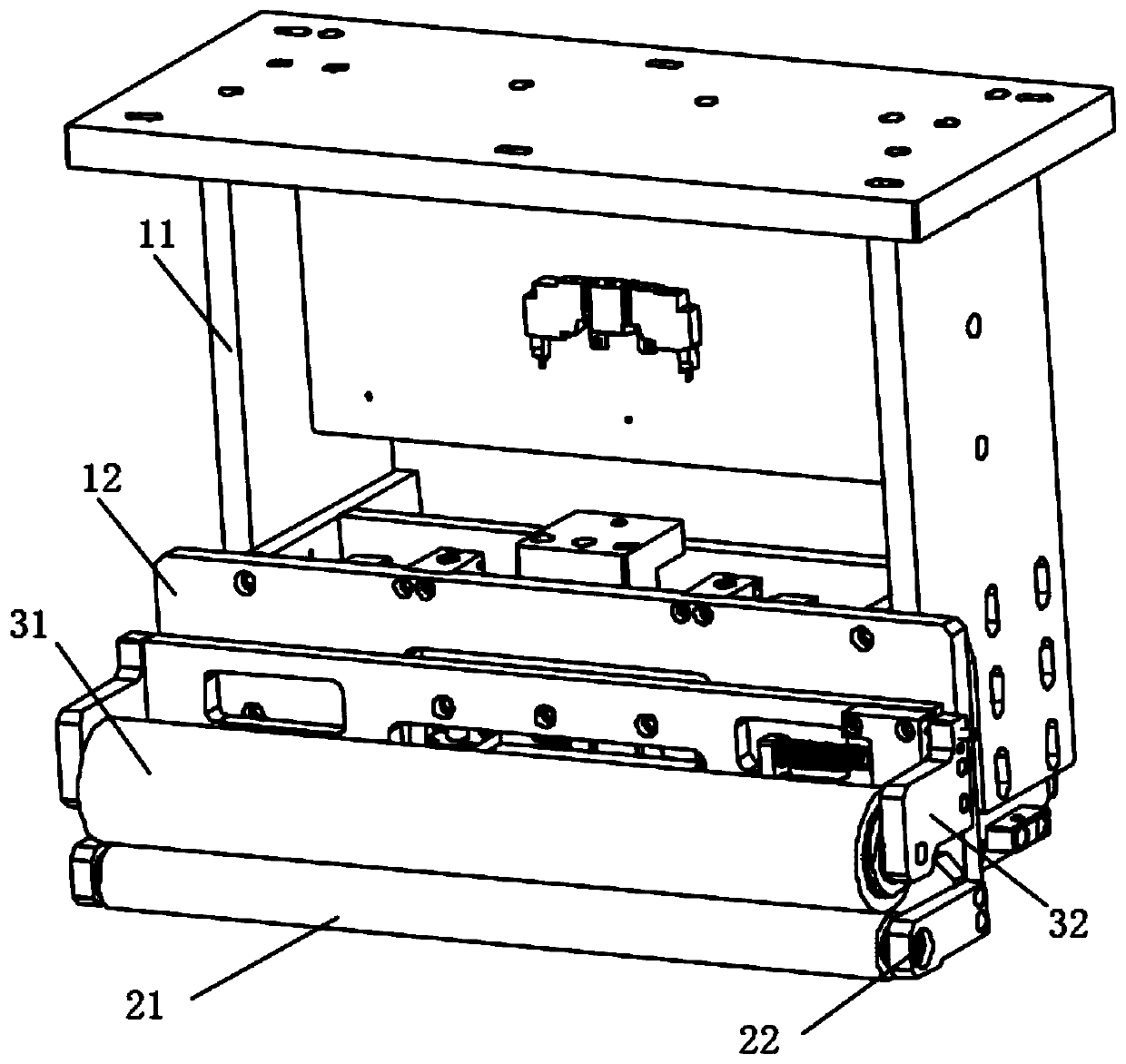

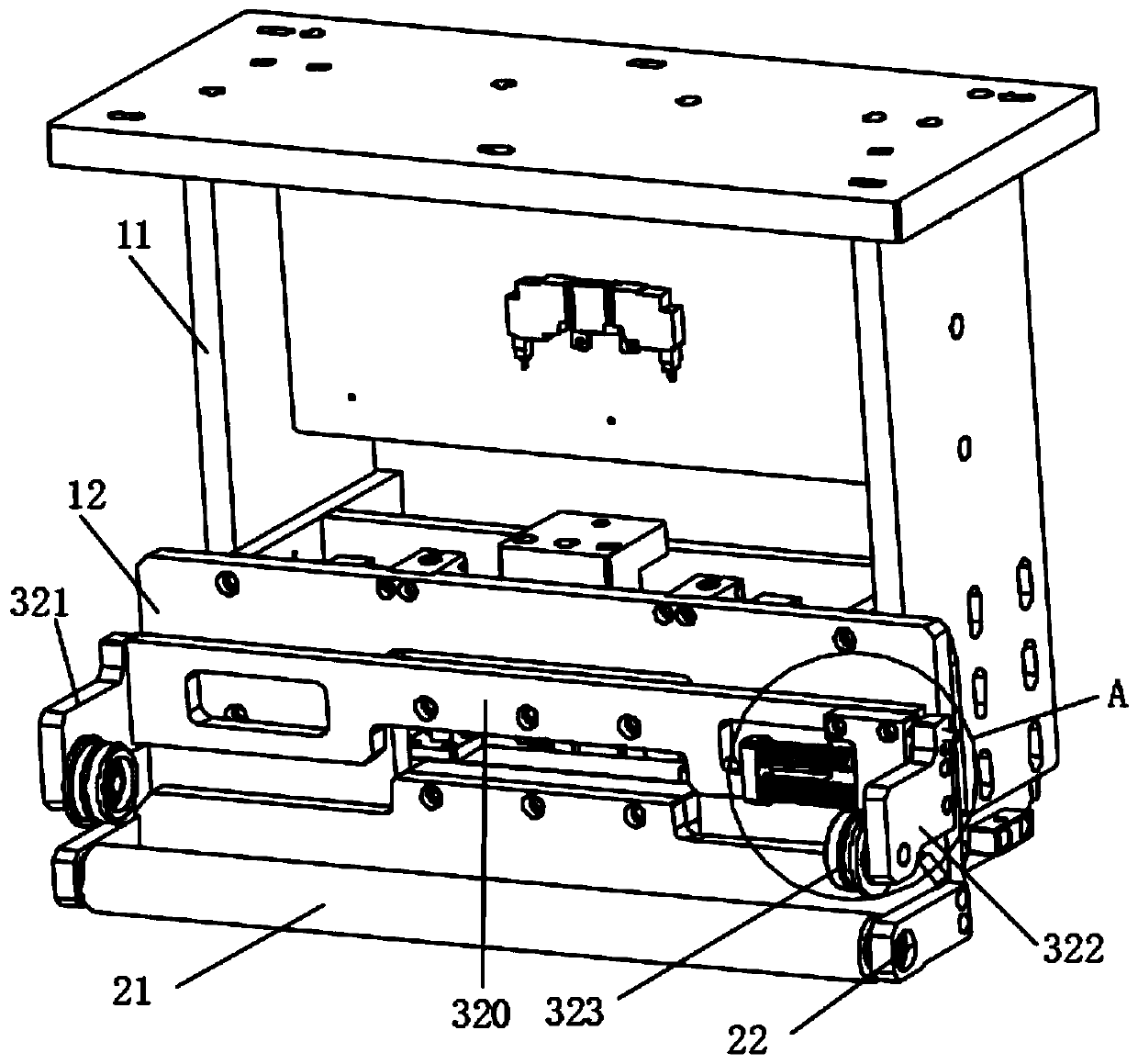

[0056] see figure 1 and figure 2 , this embodiment provides a countertop cleaning mechanism. The table cleaning mechanism can clean up the dust on the platform 100, including: a main body frame 1; a cleaning assembly 2, including a cleaning roller 21, and the roller surface of the cleaning roller 21 is provided with a viscous layer for cleaning the platform 100; a dust collection assembly 3, including Dust collection roller 31, the roller surface of dust collection roller 31 is provided with the viscous layer that is used for cleaning cleaning roller 21; Connection assembly 4, comprises elastic member 41, and cleaning assembly 2 is connected to dust collection assembly 3 by elastic member 41 (referring to Figure 7 ); the drive assembly 5, including the driver 51, the driver 51 is located on the main body frame 1, and can drive the dust collecting roller 31 to be in rolling contact with the cleaning roller 21 (see Figure 7 ).

[0057] Specifically, the axes of the cleanin...

Embodiment approach 2

[0082] This embodiment provides another countertop cleaning mechanism, which is basically the same as the countertop cleaning mechanism in Embodiment 1, the differences are:

[0083] Optionally, the driver 51 includes an oil cylinder, and the driving rod 511 is a piston rod inserted in the oil cylinder; or, the driver 51 includes a linear driver, and the driving rod 511 is an electric push rod driven by a motor.

Embodiment approach 3

[0085] This embodiment provides another countertop cleaning mechanism, which is basically the same as the countertop cleaning mechanism in Embodiment 1, the differences are:

[0086] Guide member 42 comprises slide rail, and slide rail is installed on the front plate 1201, and slide block is respectively installed on the first mount base 20 and the second mount base 30; Slide block can slide along slide rail, and first mount base 20 and second mount base The mounting bases 30 are matched to the slide rails respectively through the sliders; the length direction of the slide rails is the extending direction of the guide member 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com