Stamping die for FPC board

A technology of stamping dies and dies, which is applied in the field of FPC manufacturing, can solve problems such as pollution and difficult cleaning of liquid medicine, and achieve the effects of no pollution to the environment, low cost, and simple structure

Inactive Publication Date: 2020-06-19

黄石市联翔电子有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The burr-free FPC board needs to be etched during the production process, which is chemically etched, which has certain pollution, and the chemical solution is difficult to clean

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

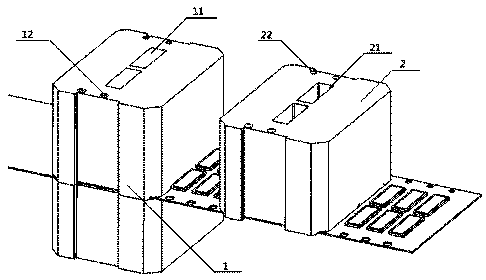

[0008] see figure 1 , The present embodiment includes a forming die 1 and a back pressure die 2, the forming die 1 is provided with a forming punch 11 and a guide post 12, and the back press die 2 is provided with a back pressure punch 21 and a back pressure guide post 22.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of FPC manufacturing, in particular to a stamping die for an FPC board. The stamping die comprises a forming die and a back-pressing die, wherein the forming die is provided with forming stamping heads and guide columns; and the back-pressing die is provided with back-pressing stamping heads and guide columns. The stamping die has no pollution and low cost.

Description

technical field [0001] The invention relates to the technical field of FPC manufacturing, in particular to a stamping die for FPC boards. Background technique [0002] The burr-free FPC board needs to be etched during the production process, which is chemically etched, which has certain pollution, and the chemical solution is difficult to clean. Contents of the invention [0003] The object of the present invention is to provide a stamping die for FPC board in order to solve the above problems. [0004] The specific solution of the present invention is: a stamping die for FPC boards, including a forming die and a back pressing die, the forming die is provided with a forming stamping head and a guide column, and the back pressing die is provided with a back pressing punch and a guide post . [0005] Compared with the prior art, the present invention has the following advantages: simple structure, low cost, no pollution to the environment, and can also produce burr-free FP...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/10

CPCB21D37/10

Inventor 吴朝阳

Owner 黄石市联翔电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com