Grinding device used for building decoration

A technology for architectural decoration and grinding discs, which is applied to grinding drive devices, grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, etc. The effect of improving stability and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

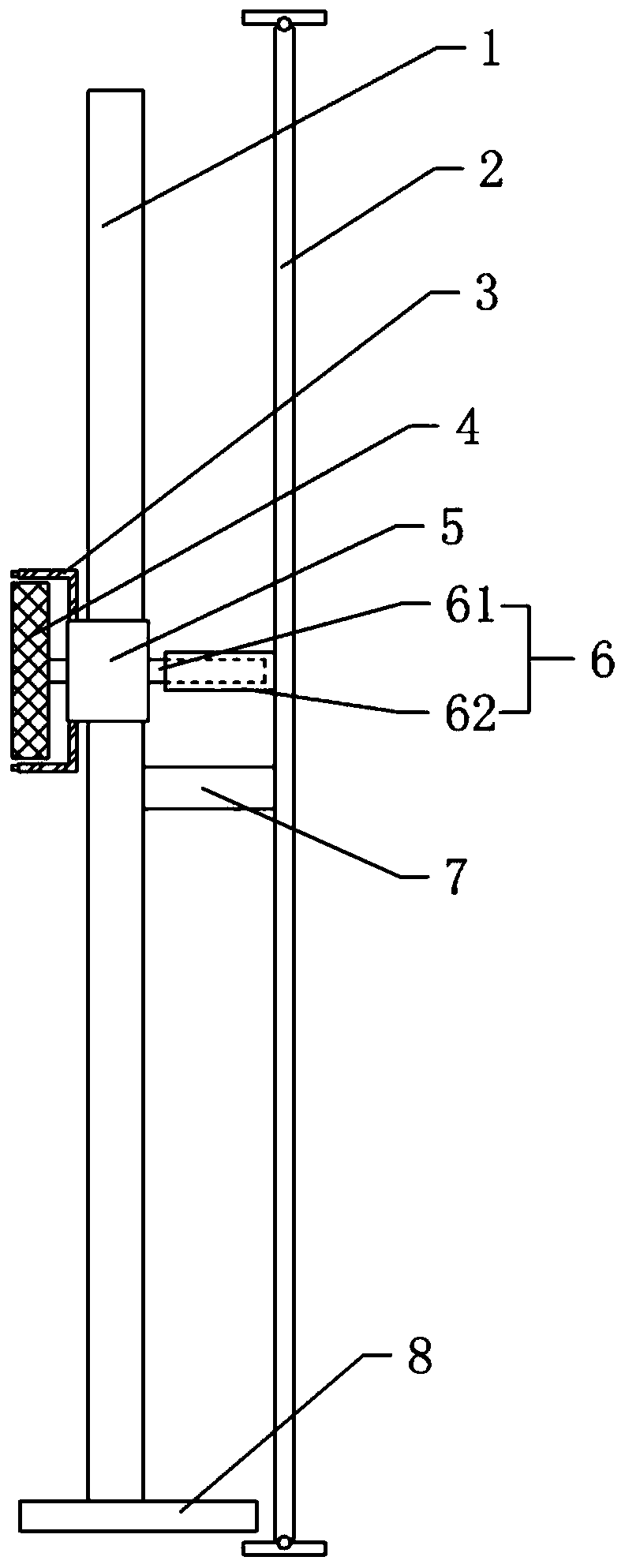

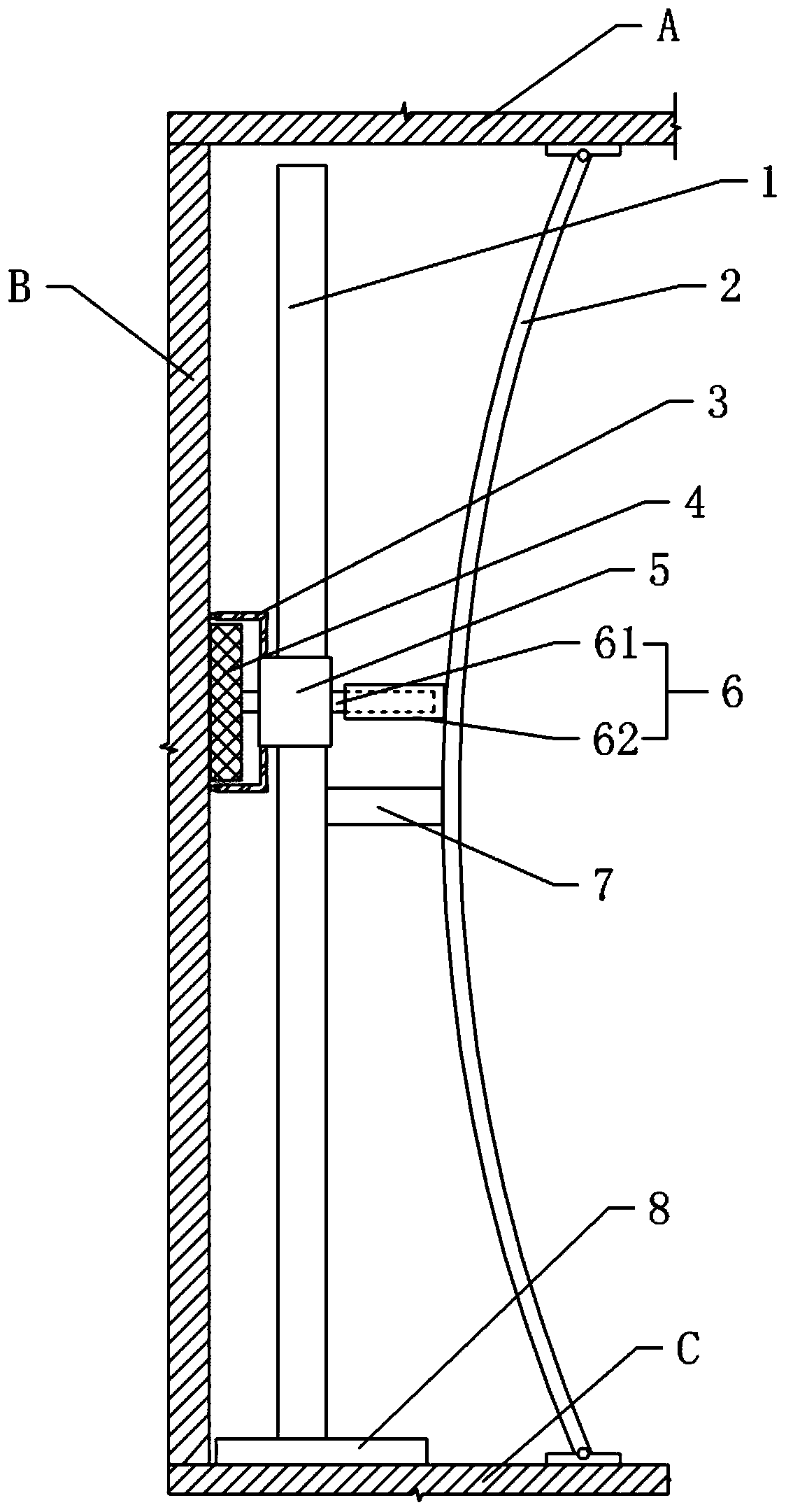

[0020] Embodiment one: as attached figure 1 Shown: the grinding device for architectural decoration, including a bracket, the bracket includes a base 8 and a vertical guide rod 1, the guide rod 1 is slidably connected with the base 8 in the horizontal direction, and the bottom of the base 8 is equipped with a walking wheel. In this embodiment, the walking wheel Preferably it is a universal wheel. The right side of the guide rod 1 is provided with a vertical elastic plate 2 , and a connecting rod 7 is welded between the middle part of the elastic plate 2 and the middle part of the guide rod 1 . The upper end of the elastic plate 2 is hinged with an upper top block that can be pressed against the ceiling A, and its lower end is hinged with a lower top block that can be pressed against the floor C. The side of the elastic plate 2 facing the guide bar 1 is vertically provided with a slide groove.

[0021] Slide block 5 is vertically slidably connected on guide bar 1, and slide b...

Embodiment 2

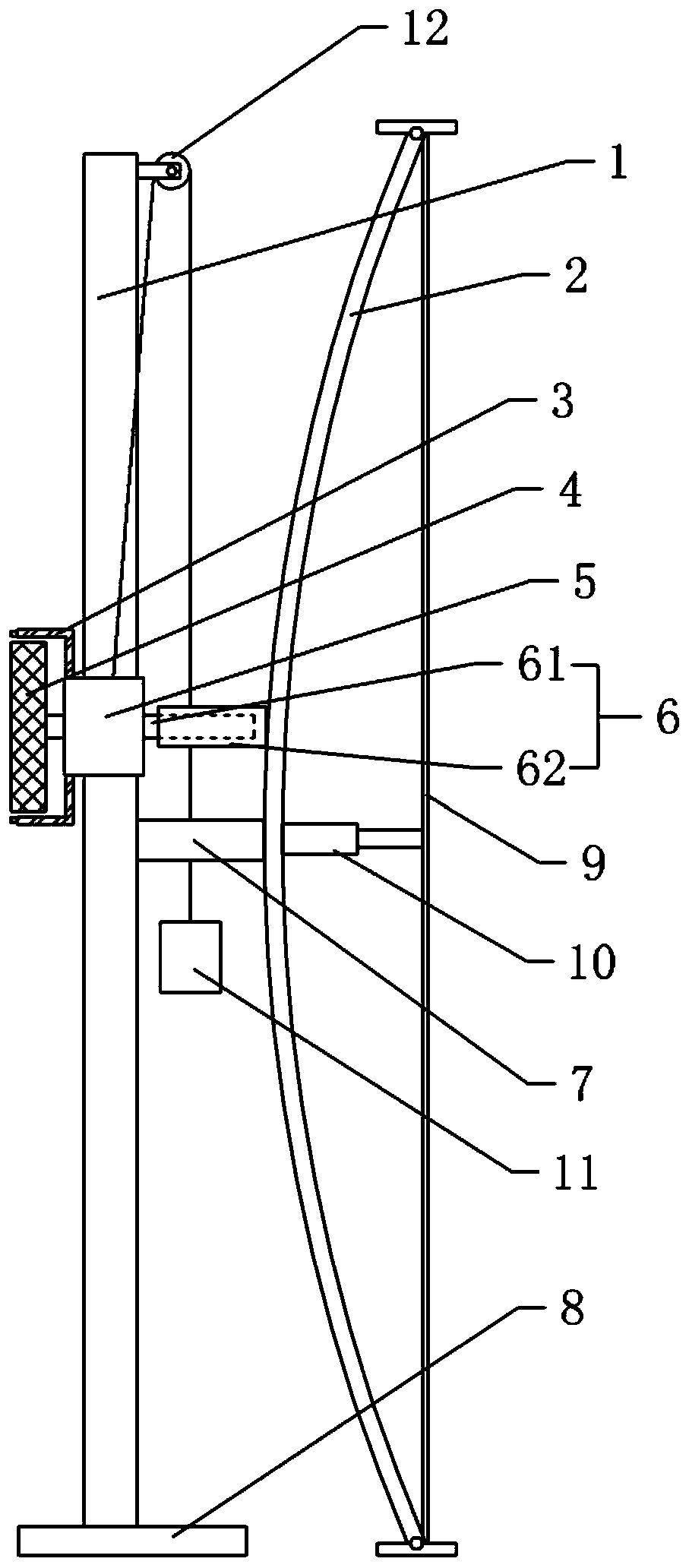

[0023] Embodiment two: the difference with embodiment one is only: as image 3 As shown, the upper end of the guide rod 1 is rotated with a fixed pulley 12, the fixed pulley 12 is wound with a traction rope, one end of the traction rope is connected with the slider 5, and the other end of the traction rope is connected with a counterweight 11; A stay rope 9 is connected between the upper and lower ends of the upper and lower ends; a telescopic adjustment mechanism 10 is connected between the stay rope 9 and the middle part of the elastic plate 2. In the present embodiment, the telescopic adjustment mechanism 10 is preferably a jack mechanism, and one end of the jack is connected with the bolt by a bolt. The middle part of elastic plate 2 is connected and fixed, and the other end of the jack is connected with the middle part of stay cord 9 . The weight of counterweight 11 is slightly less than the sum of the weights of all mechanisms installed on the slide block 5, utilize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com