Hydraulic control lifting type device for traction fault vehicle

A lift-type, faulty vehicle technology, which is applied to vehicles used for freight, repaired damaged vehicles, and vehicles with cranes, etc. It can solve problems such as difficult loading and unloading, inability to prevent tilting or falling off, inconvenient limit fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

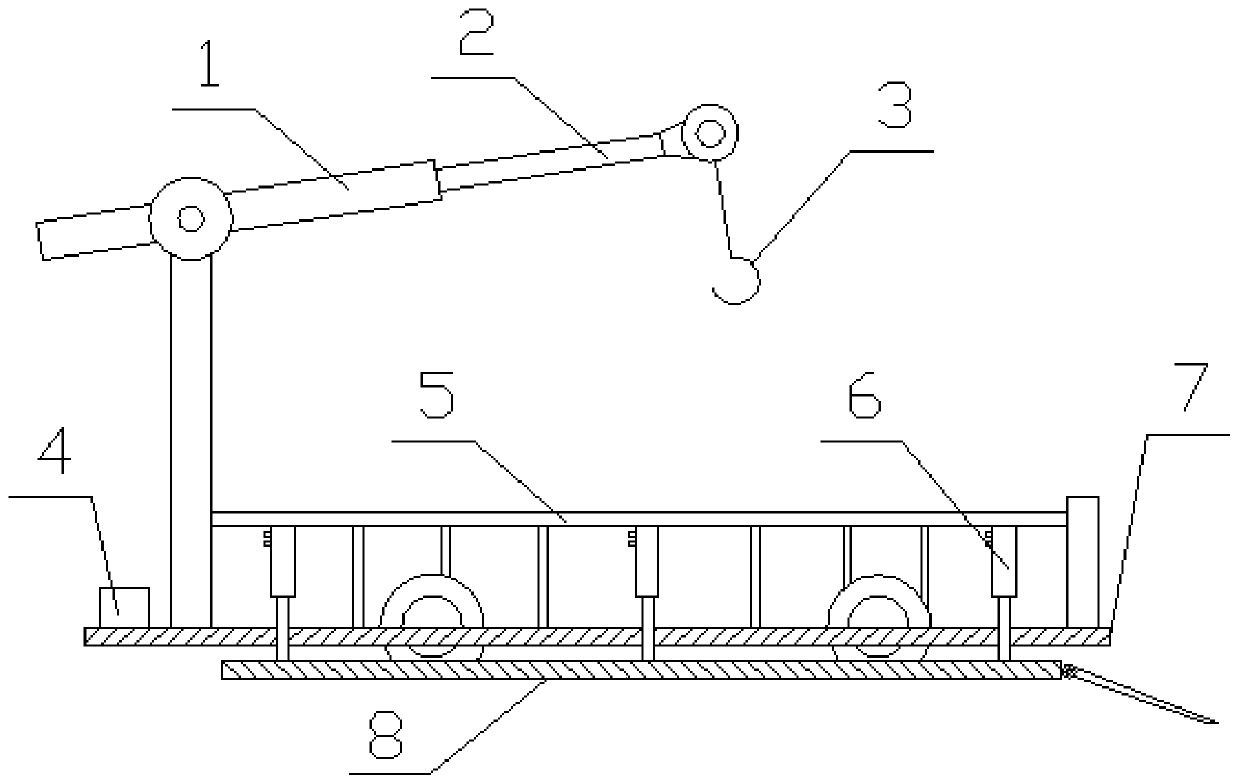

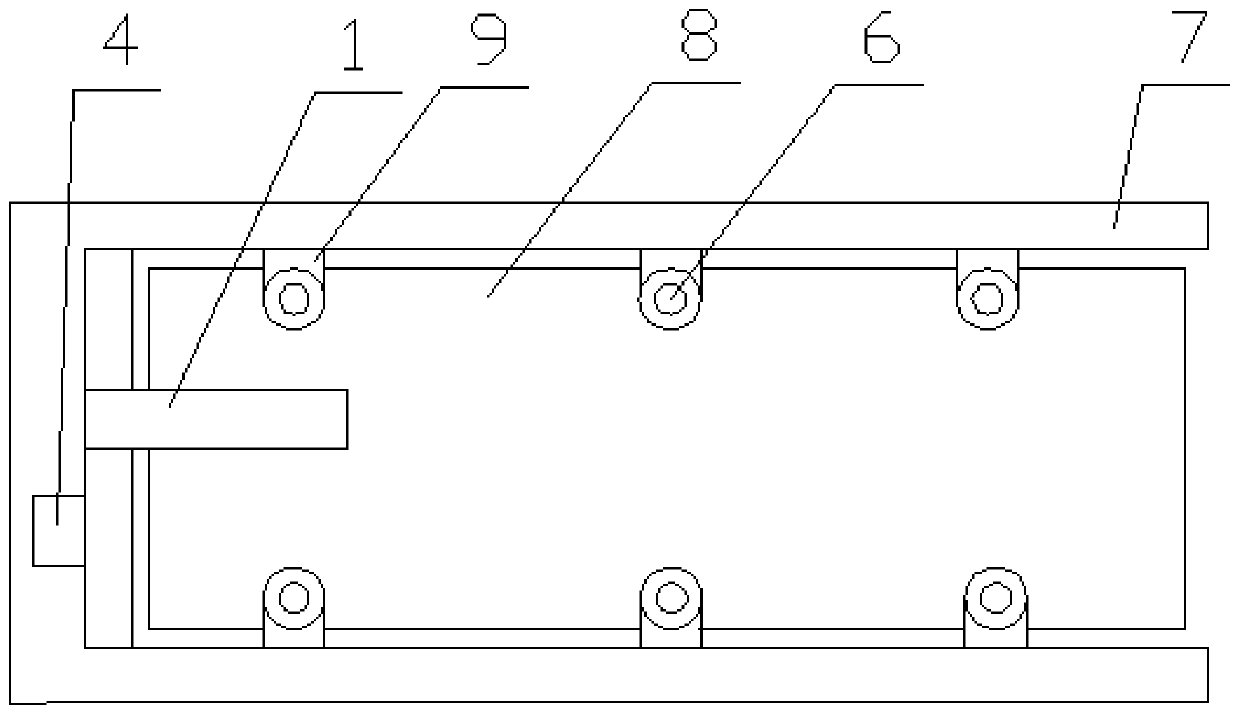

[0024] A special trailer for lifting and lowering accident vehicles by hydraulic control, comprising:

[0025] 1. Small crane, 2. Telescopic arm, 3. Hook, 4. Hydraulic control mechanism, 5. Trailer guardrail, 6. Hydraulic cylinder, 7. U-shaped frame, 8. Trailer floor, 9. Mounting arm.

[0026] The small crane 1 is connected with the telescopic arm 2 of the small crane, the hook 3 is connected with the telescopic arm 2 of the small crane through a wire rope, the small crane 1 is fixed on the U-shaped frame 7 of the trailer, and the hydraulic control mechanism 4 is also fixed on the U-shaped frame 7 of the trailer Above, the trailer guardrail 5 is fixedly connected with the U-shaped frame 7, the upper end of the hydraulic cylinder 6 is fixedly connected with the trailer guardrail 5 through the cylinder mounting arm 9, the lower end of the hydraulic cylinder 6 is directly fixedly connected with the trailer floor 8, and the hydraulic control mechanism 4 is connected through the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com