Building wallboard structure based on foam material

A foamed material and building wall technology, applied in building components, building structures, buildings, etc., can solve problems such as difficult support, prone to deformation, hidden dangers, etc., to achieve convenient handling and assembly, ensure stability, and enhance the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

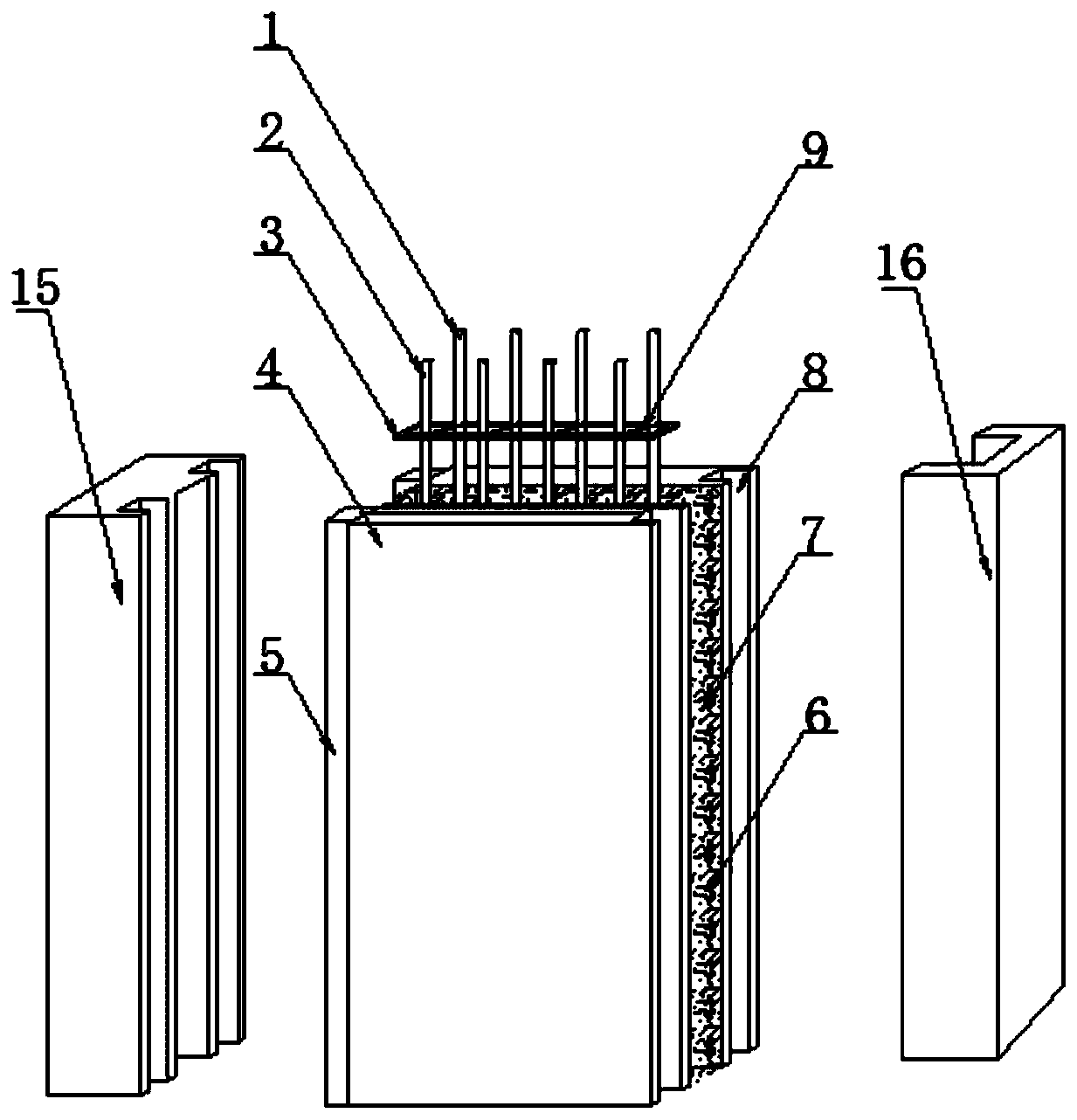

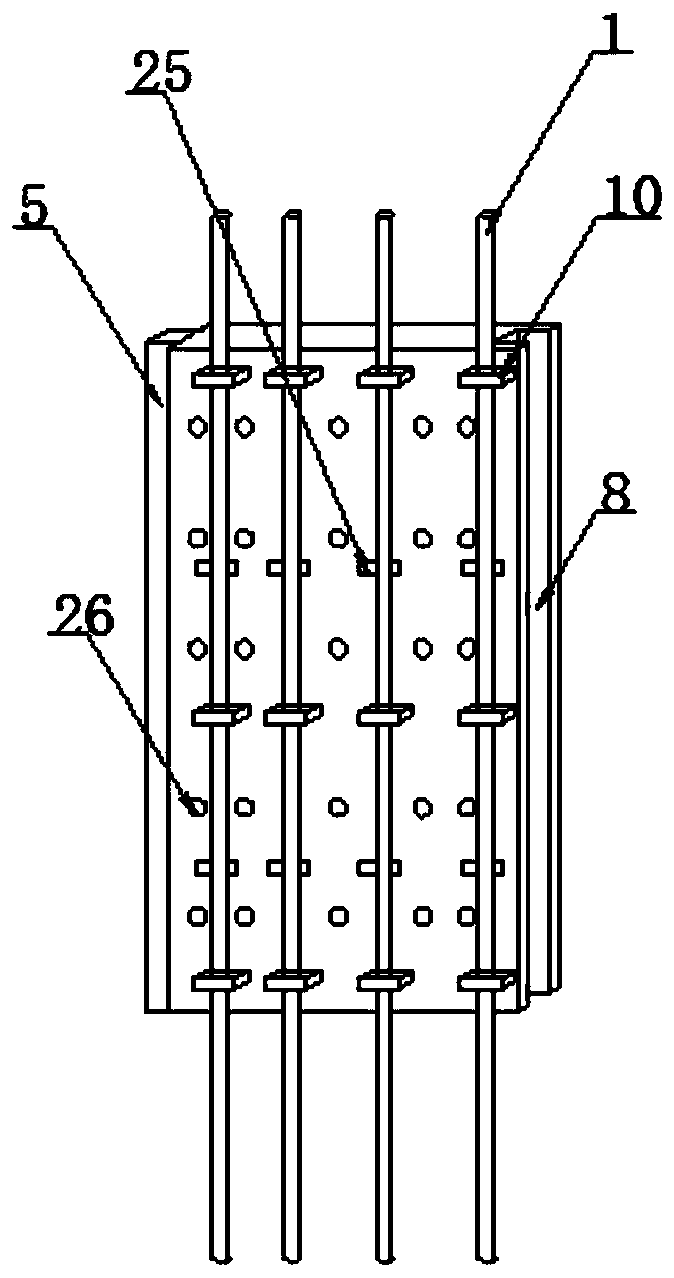

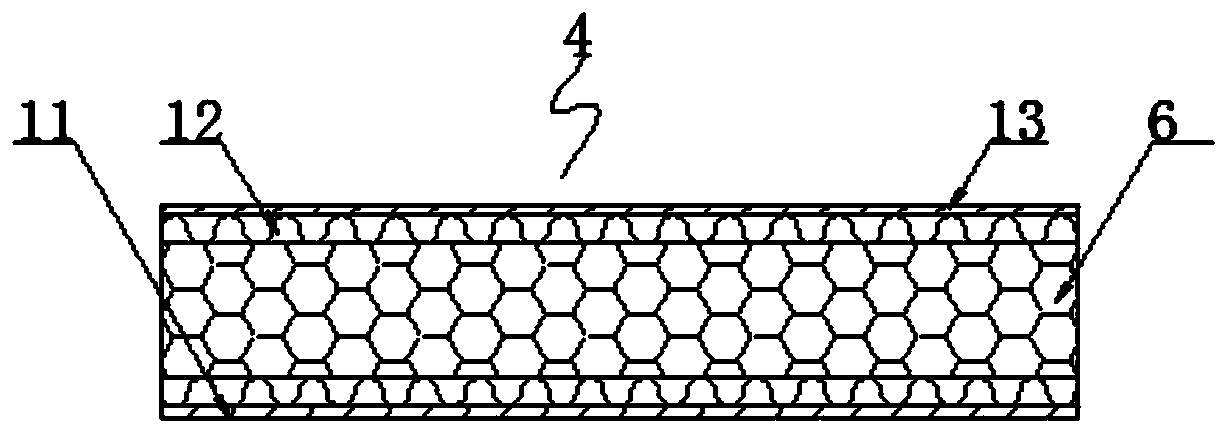

[0024] see Figure 1~4 , in the embodiment of the present invention: a building wallboard structure based on foam materials, including a first board 4, a second board 7, a concave clip 15, a convex clip 16 and a connection positioning mechanism, wherein the first A foaming material accommodation cavity is arranged between the plate 4 and the second plate 7, and the connection and positioning mechanism between the first plate 4 and the second plate 7 is connected and fixed. It is characterized in that the connection and positioning mechanism is along the Extending in the direction of the plane parallel to the plane of the first plate 4 or the second plate 7, the two ends of the first plate 4 and the second plate 7 adopt the concave clamping plate 15 and the convex clamping plate 16 respectively. Fastened and fixed, and a sealing gasket is arranged between the concave clamping plate 15 and / or the convex clamping plate 16 and the first plate 4 and the second plate 7, and the foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com