Optional clutch

A technology of clutches and coupling sleeves, applied in clutches, mechanically driven clutches, clutches that mesh with each other, etc., can solve the problems of large volume, clutch transmission torque limitation, etc., achieve the effect of small volume, large load torque, and overcoming high heat and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

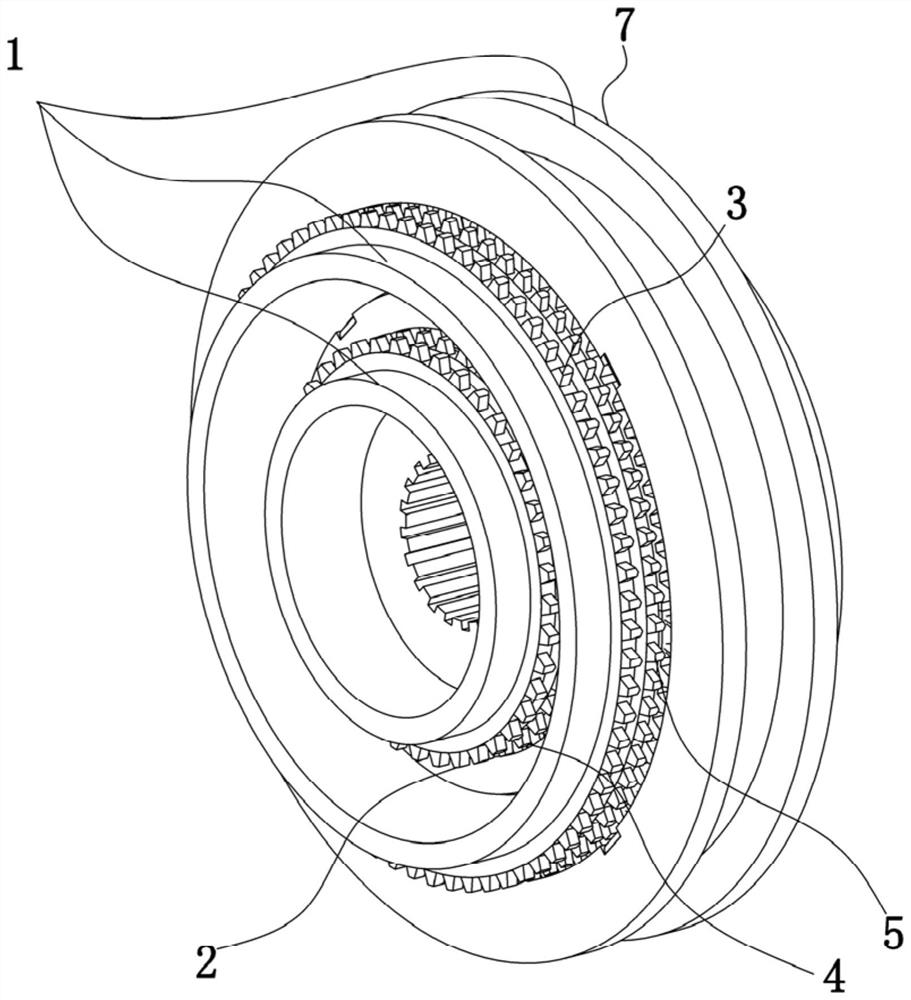

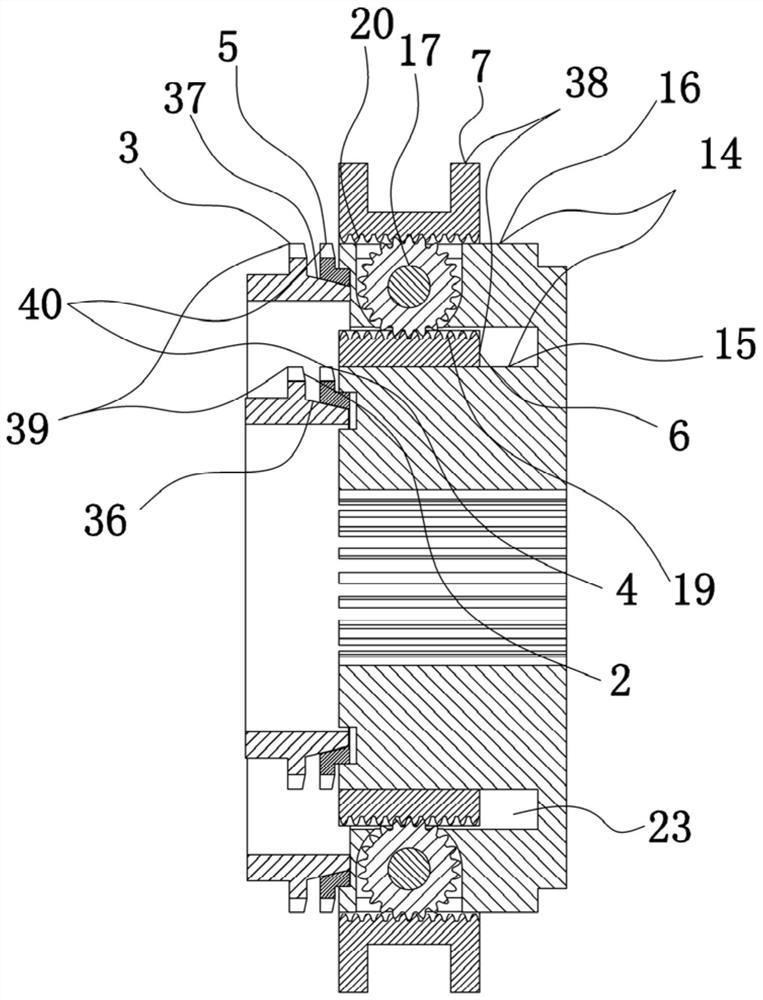

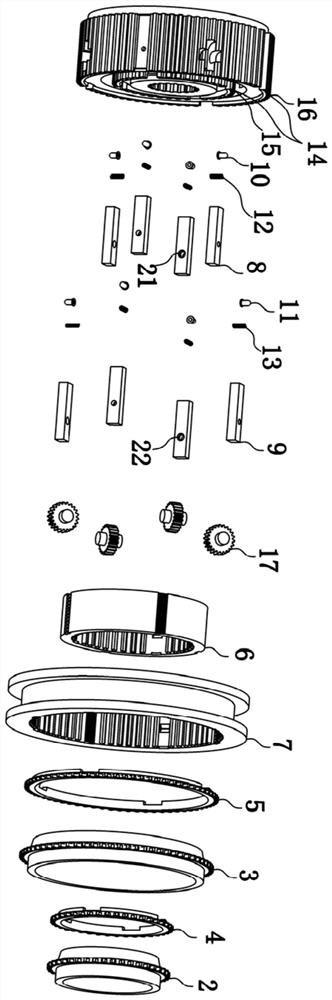

[0021] Such as Figure 1-8 As shown, a selectable clutch has: an inner ring coupling sleeve 6, an outer ring coupling sleeve 7, a spline hub 14, an inner ring coupling ring gear 2 and an outer ring coupling ring gear 3, and is characterized in that: a spline hub 14 There are two integrated coaxial inner ring spline hubs 15 and outer ring spline hubs 16, and the outer ring joint sleeve 7 is provided with an outer ring joint that matches the spline teeth 35 of the outer ring spline hub. The sleeve inner spline teeth 33 are sleeved on the outer ring spline hub 16, the inner ring joint sleeve 6 is provided with the inner ring joint sleeve inner spline teeth 32 matched with the inner ring spline hub spline teeth 34, and the inner ring joint sleeve inner spline teeth 32 are arranged. The coupling sleeve 6 is installed in the inner ring coupling sleeve installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com