Soil shear strength testing equipment and testing method

A technology of shear strength and testing equipment, which is applied in the direction of applying stable shear force to test material strength, strength characteristics, measuring devices, etc., which can solve the lack of accurate judgment and measurement data that affect surveyors on the stability of soil layers Insufficient precision and other problems, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

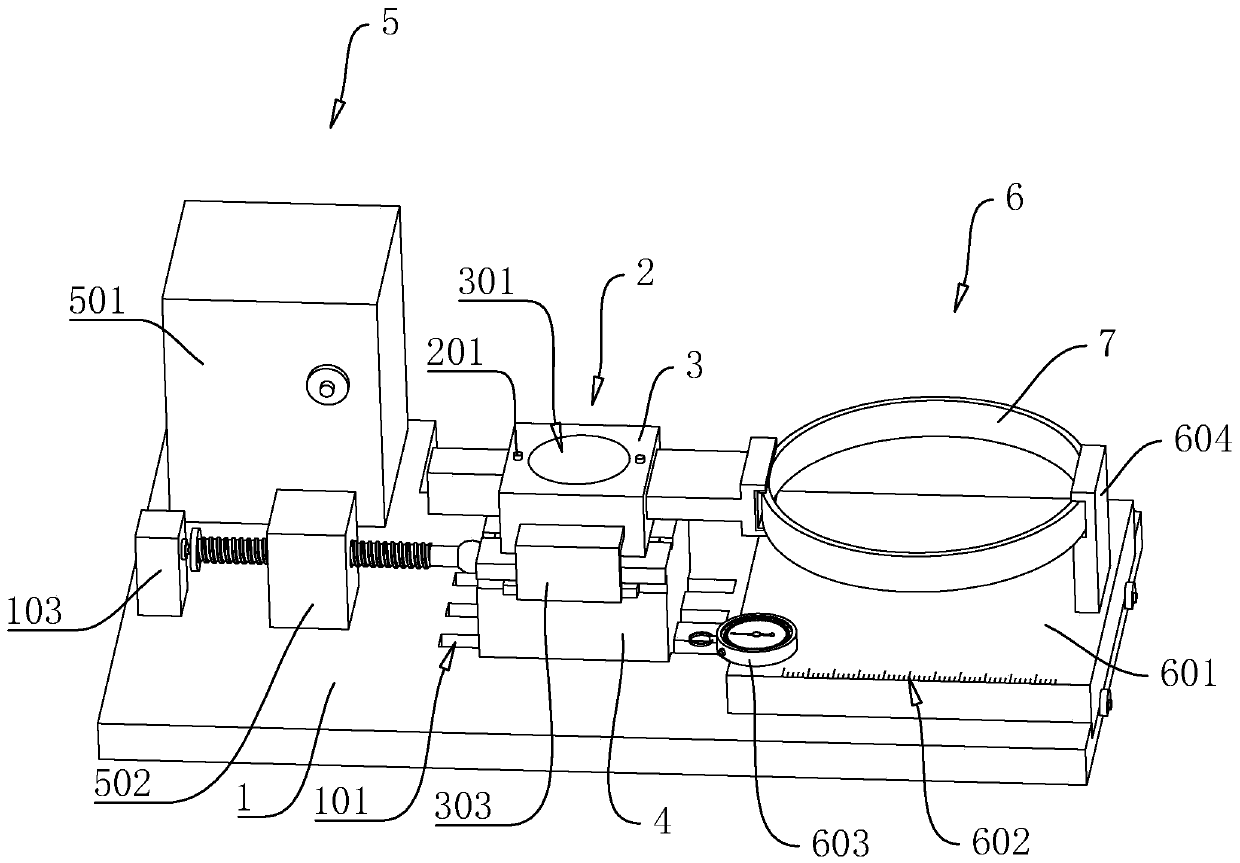

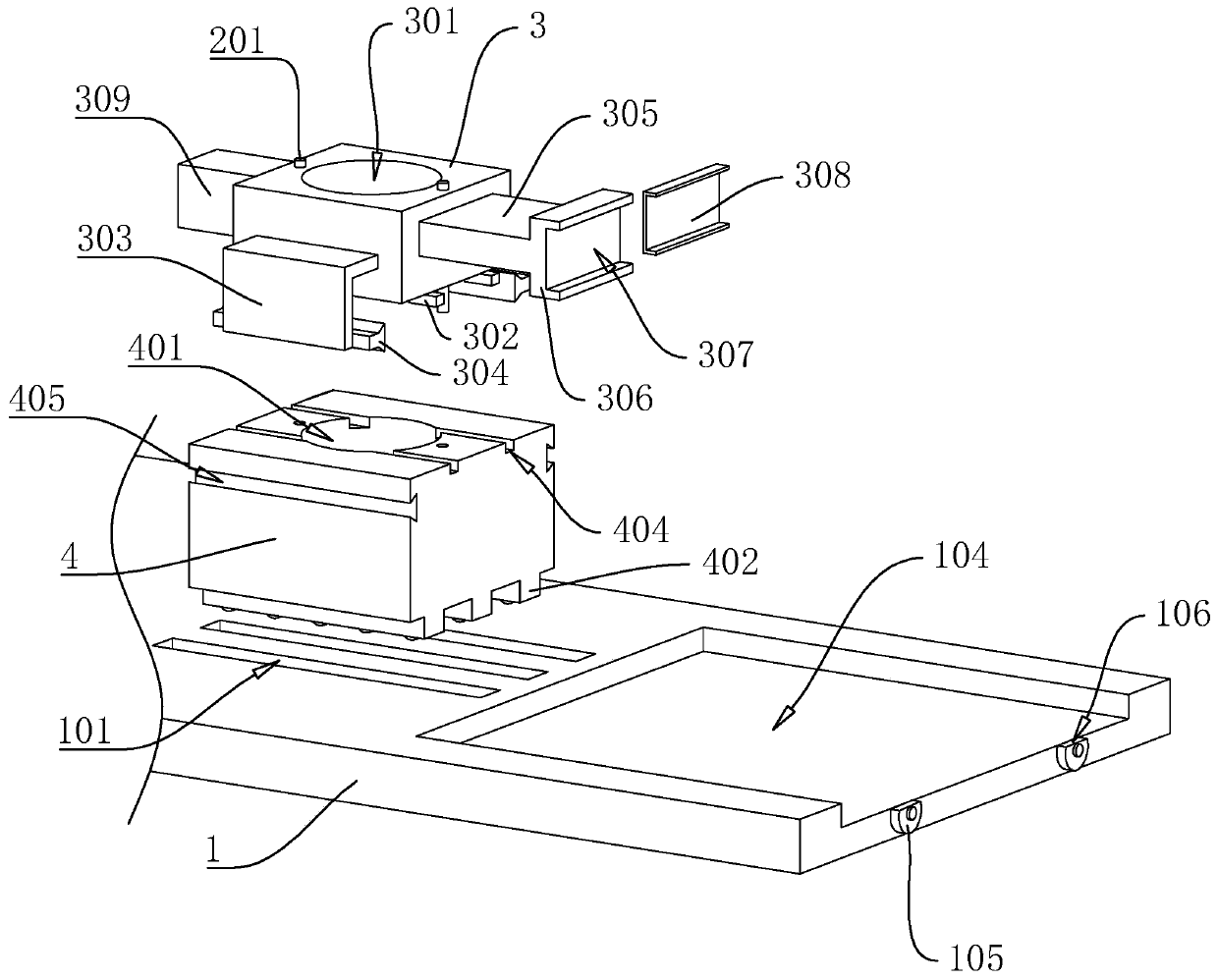

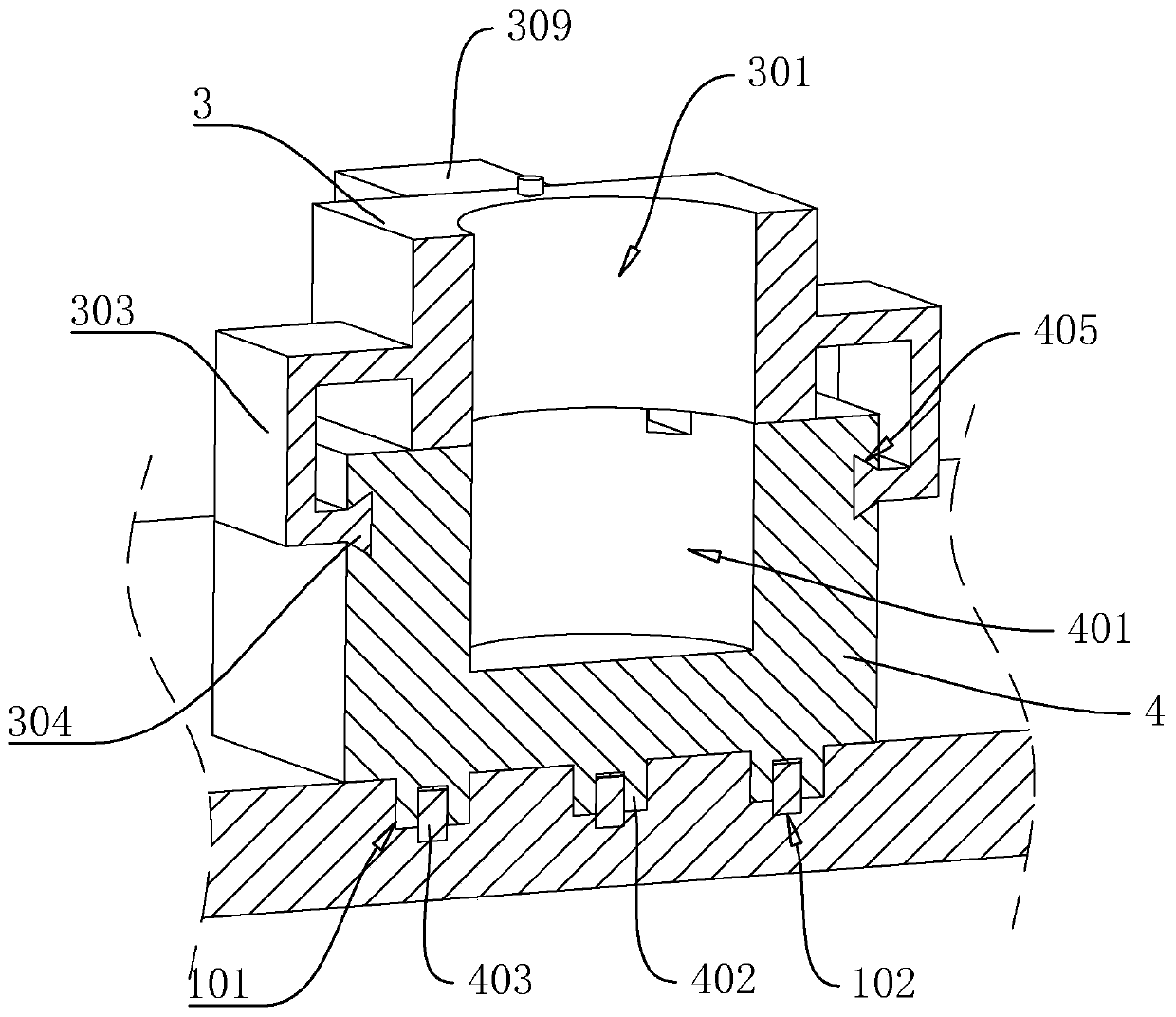

[0042] A kind of soil shear strength test equipment, with reference to figure 1 , figure 2 and image 3 , including a bottom plate 1 and a shear box 2 located on the bottom plate 1 . The shearing box 2 includes a lower box 4 and an upper box 3 slidably arranged on the lower box 4, and a positioning pin 201 is arranged between the upper box 3 and the lower box 4 to limit the relative slippage between the two. The upper surface of the upper box 3 is provided with a first through hole 301 along its own thickness direction, and the upper surface of the lower box 4 is provided with a second through hole 401. The first through hole 301 and the second through hole 401 are jointly used to place the The soil is agglomerated, and the inner bottom wall of the second through hole 401 is used to bear the soil agglomerates.

[0043] refer to figure 2 and image 3 , the upper surface of the bottom plate 1 is provided with a plurality of sliding grooves 101, and the bottom wall of the ...

Embodiment 2

[0056] A test method for soil shear strength testing equipment, comprising the following steps:

[0057] Sample preparation: first cut the undisturbed soil into rectangular agglomerates with a flat outer surface with a ring knife. When cutting the undisturbed soil, ensure that the solid-liquid-gas three-state balance of the undisturbed soil is cut, that is, the undisturbed soil is not sticky or loose after cutting. After standing for 20 minutes, it still maintains a specific shape; then use a cylinder with a sharp bottom to open a mold on the rectangular agglomerate to obtain a cylindrical sample.

[0058] Debugging the sample: pass the cylindrical sample through the first through hole 301 and into the second through hole 401, and adjust its position so that the position of the cylindrical sample in the shear box 2 tends to be stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com